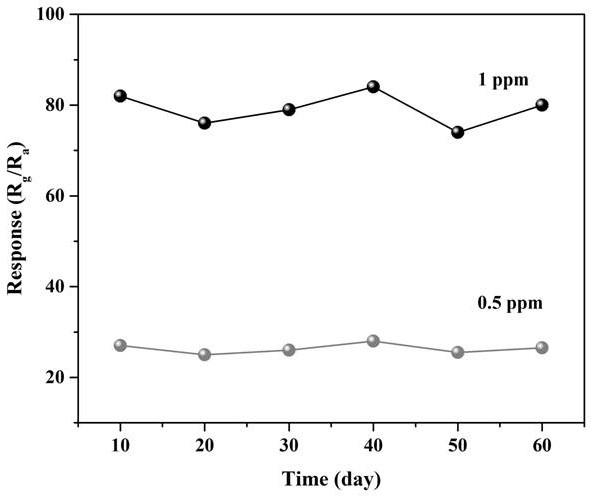

A 3dom In modified by n-gqds 2 o 3 Composite materials and their preparation methods and applications

A composite material, 3domin2o3 technology, applied in the field of N-GQDs modified 3DOMIn2O3 composite material and its preparation, can solve the problems of long recovery time, poor selectivity, unfavorable practical application, etc. Beneficial for adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A 3DOM In modified by N-GQDs 2 o 3 Preparation method of composite material:

[0026] (1) N-GQDs were synthesized by a one-step hydrothermal method. The specific steps were as follows: 10 mg of graphene oxide (synthesized by the improved Hummers method) was mixed with 18 mL of secondary water and 2.0 mL of ammonia water (28wt%), and ultrasonicated for 30 After 1 min, the mixture was transferred to a reaction kettle lined with polytetrafluoroethylene, solvothermally heated at 180 °C for 12 h, cooled to room temperature naturally, and the mixed solution was filtered through a 25 nm microporous membrane to remove the black precipitate, and the golden yellow filtrate was spun Concentrated by evaporation, and further purified in a 1000da dialysis bag for 1 day to remove excess ammonia, and dried in vacuum to obtain N-GQDs;

[0027] (2) Synthesis of 3DOM In by impregnation-calcination method 2 o 3 , the specific steps are:

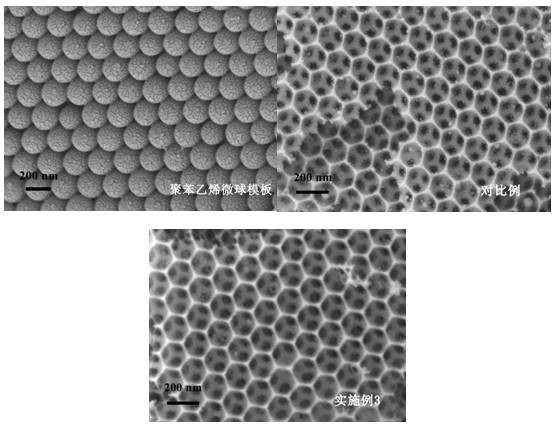

[0028] (2a) Preparation of polystyrene microsp...

Embodiment 2

[0032] The difference from Example 1 is that the N-GQDs in step (1) is 0.5 mg.

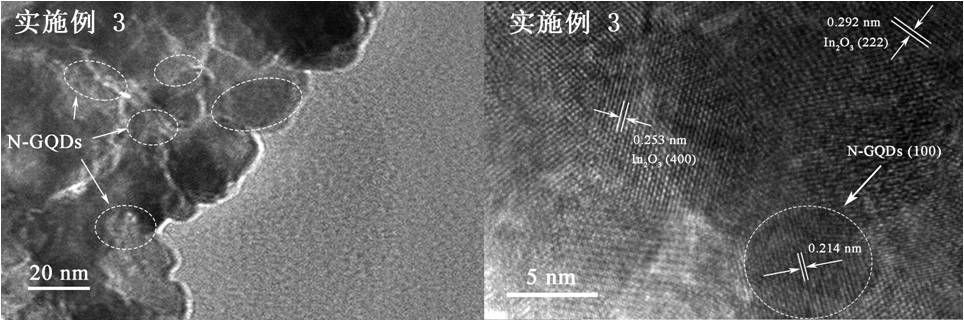

Embodiment 3

[0034] The difference from Example 1 is that the N-GQDs in step (1) is 1.0 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com