Civil engineering shielding engineering wall member

A wall and component technology, applied in the field of civil engineering shielding wall components, can solve the problems of increasing the cost of walls, increasing the difficulty and cost of wall construction, and being unsuitable for civil engineering applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

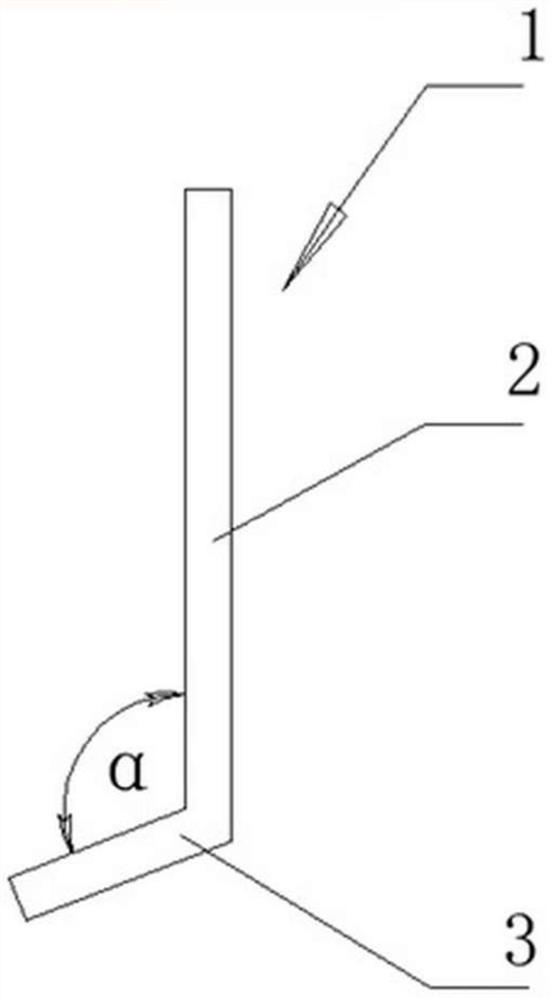

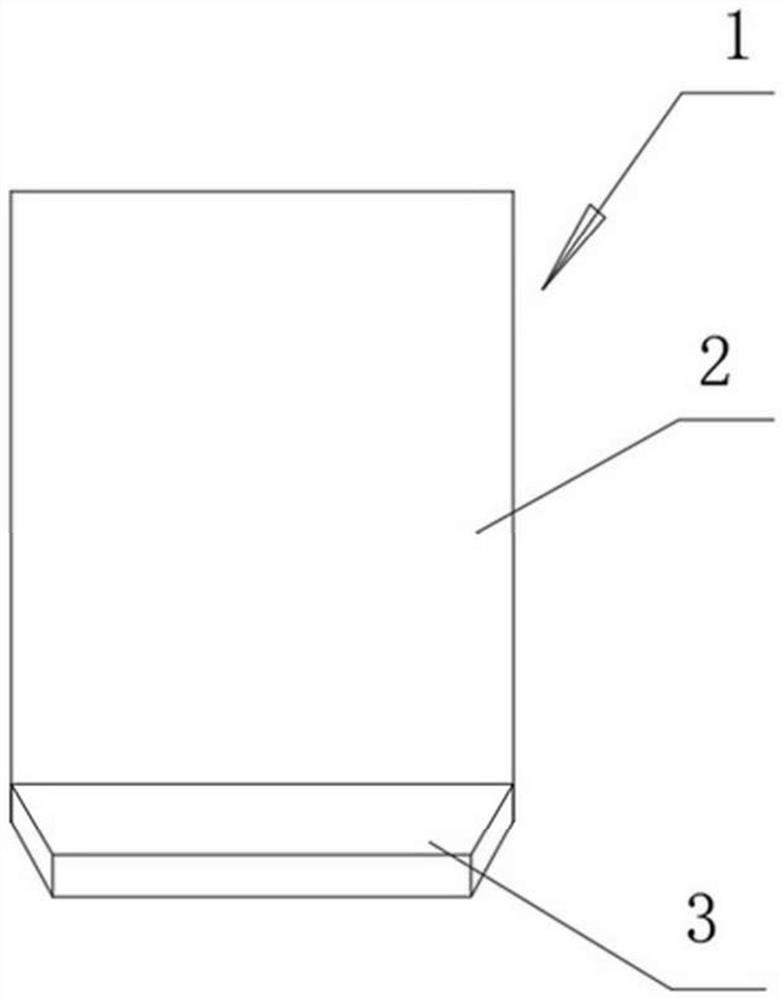

[0051] The first embodiment: In order to improve the performance of the existing retaining wall, a civil shielding engineering wall component is provided. Such as figure 1 , figure 2 , image 3 As shown, the main body of this wall component 1 is also an upright wallboard 2, and a bottom plate 3 extending to one side of the wallboard is provided below the wallboard. The improvement is: the wall board and the bottom board are fixedly connected together, preferably reinforced cement concrete prefabricated parts. The included angle between the wall board and the bottom board is not a right angle, but an obtuse angle greater than 90 degrees. According to a large number of experiments and calculations, the obtuse angle should be between 100-110 degrees, preferably 105 degrees.

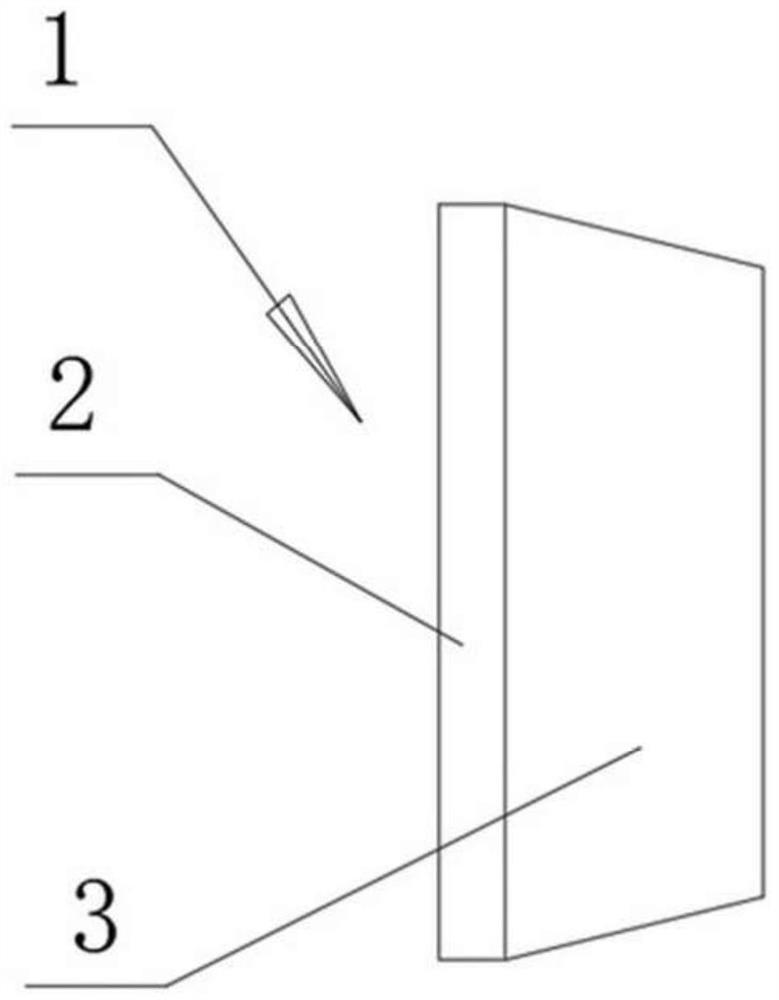

[0052] Figure 4 The installation structure of the previous wall panel is introduced. The angle between the wall panel and the bottom plate in the figure is 90 degrees. The installation requires a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com