Device and method for visual detection of tools in shield soil cabin

A detection device and shield soil technology, which is applied in the field of geotechnical engineering, can solve problems such as difficult to complete the hob full surface imaging, affecting the accuracy of 3D modeling of the hob, and achieve the effect of reducing the dead angle of shooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

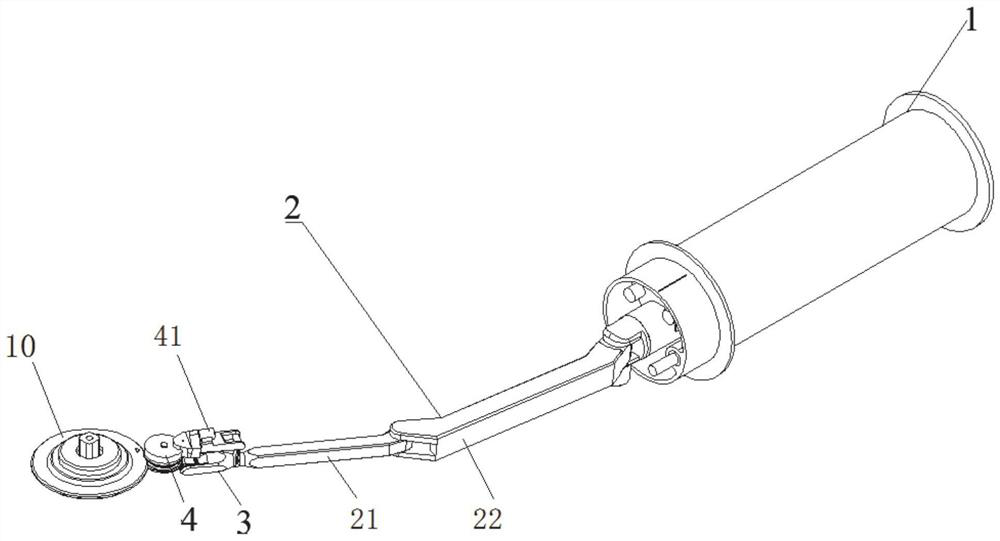

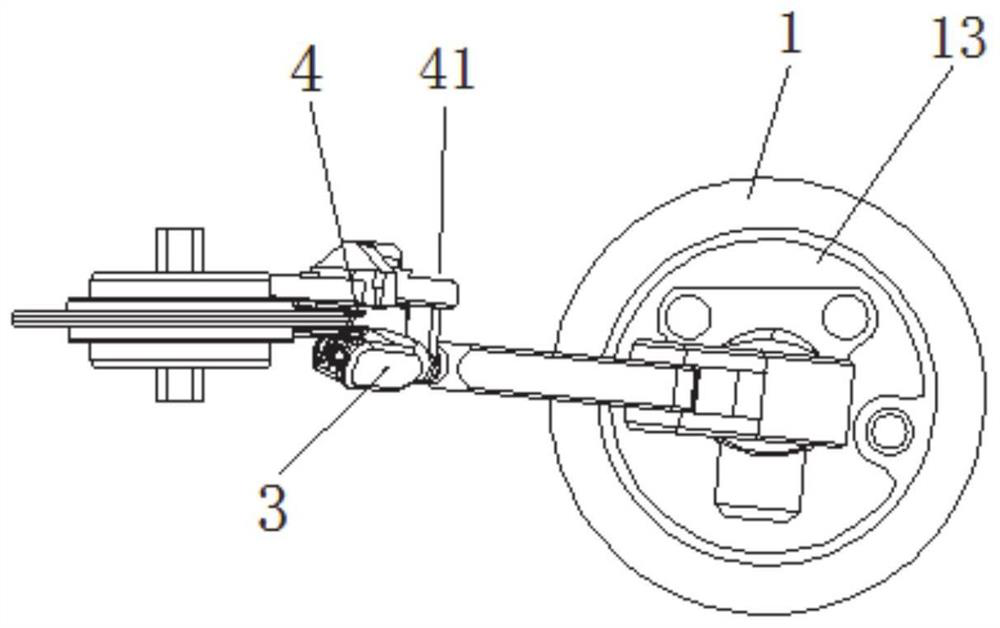

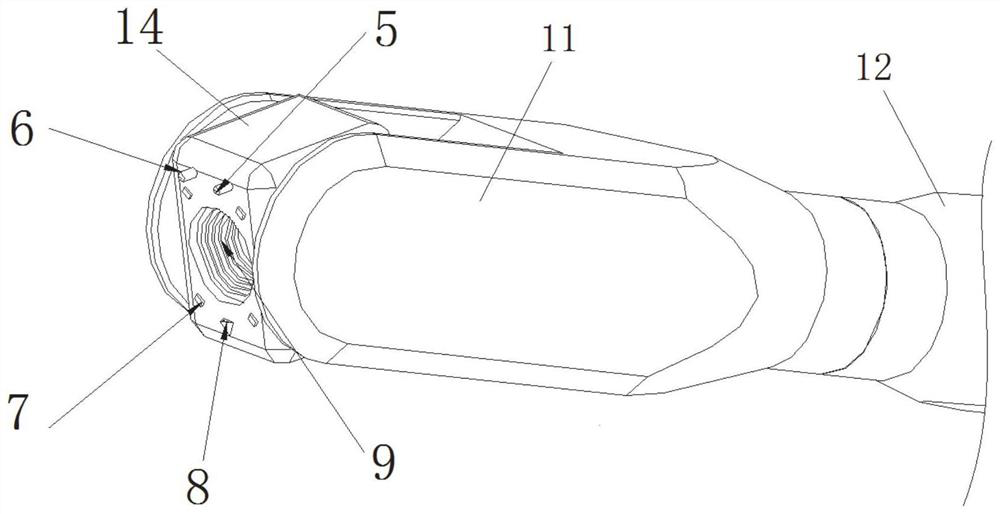

[0030] like Figure 1-Figure 3 As shown in the figure, this embodiment provides a visual detection device for tools in a shield tunneling chamber, including a host computer, a detection component and a driving component. The driving component can drive the detection component to enter or leave the shield tunneling chamber from the bulkhead board; the detection component Including a multi-joint robotic arm 2, the end 12 of the robotic arm is equipped with a binocular camera 9 through a multi-axis turntable 3, and the multi-axis turntable 3 can drive the binocular camera 9 to rotate along multiple axes; the end of the robotic arm 2 is installed with a drive wheel. Rotating the driving mechanism 4, the driving wheel can contact with the hob 10 and drive the hob 10 to rotate; the host computer can communicate with the binocular camera 9 to complete the three-dimensional modeling of the hob 10, and judge the degree of wear of the hob 10.

[0031] It should be noted that the multi-j...

Embodiment 2

[0044] This embodiment provides a method for visual detection of tools in a shield soil cabin, using the device for visual detection of tools in a shield soil cabin described in Embodiment 1, including the following steps:

[0045] Before the shield machine excavates, the detection component enters the shield tunnel, the movement of the mechanical arm makes the driving wheel and the binocular camera align with different hob in turn, the driving wheel drives the hob to rotate, and the binocular camera is turned on to take pictures automatically. The image information completes the three-dimensional modeling program. The three-dimensional model includes the spatial coordinate system of the end of the detection device and the morphological model of the cutter head and the hob. After the initial model of the shield tool is built, the detection device is retracted to the storage component.

[0046] After the shield machine has been working normally for a period of time, when the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com