ToF-based welding seam recognition method

A recognition method and weldment technology, applied in the field of weld seam recognition, can solve the problems of environmental restrictions, large amount of calculation, and inability to determine three-dimensional information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

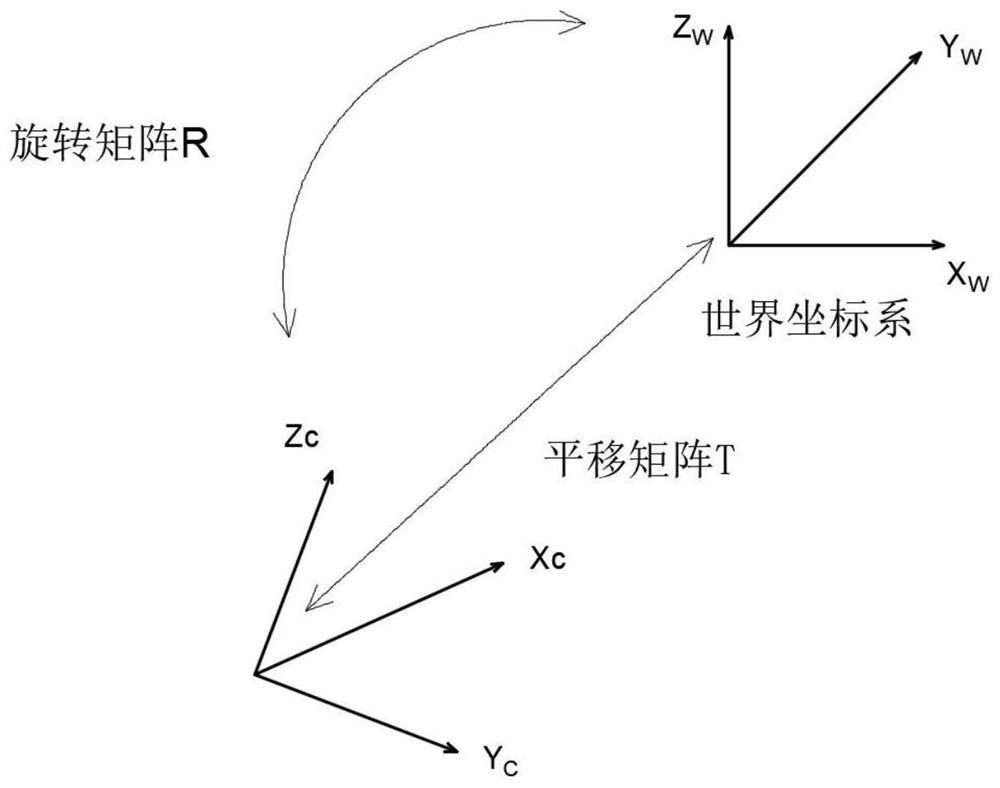

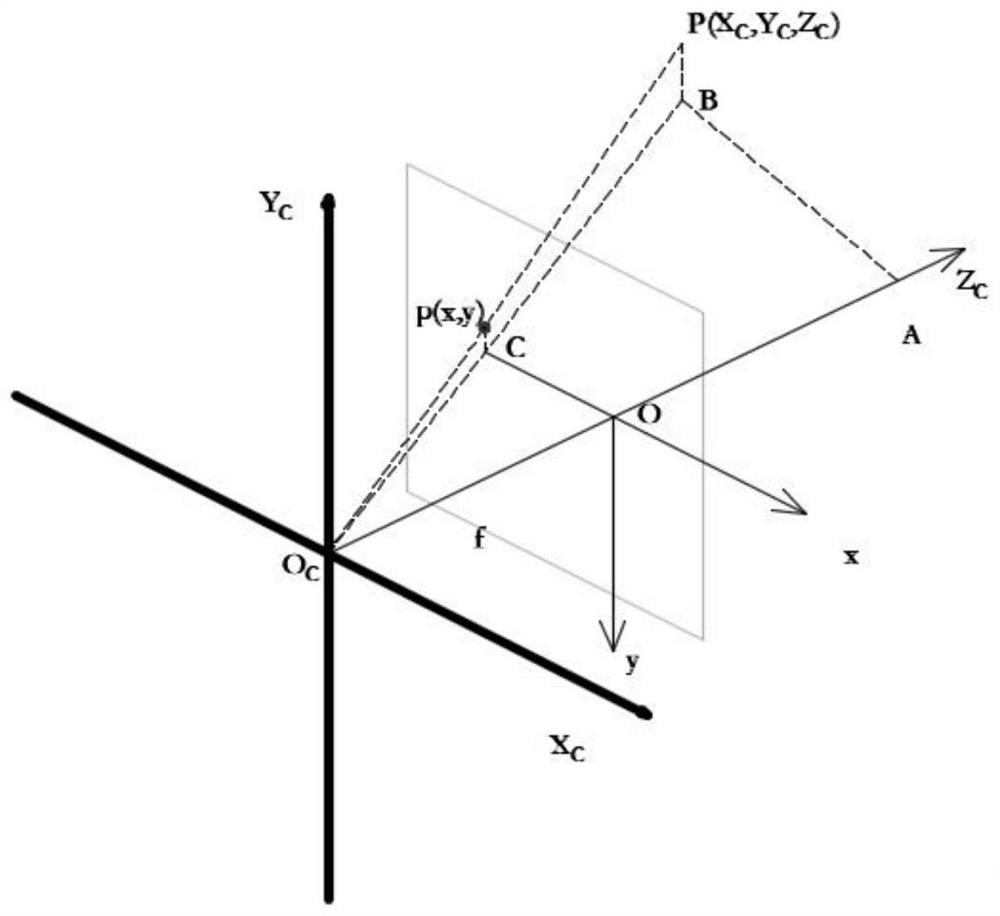

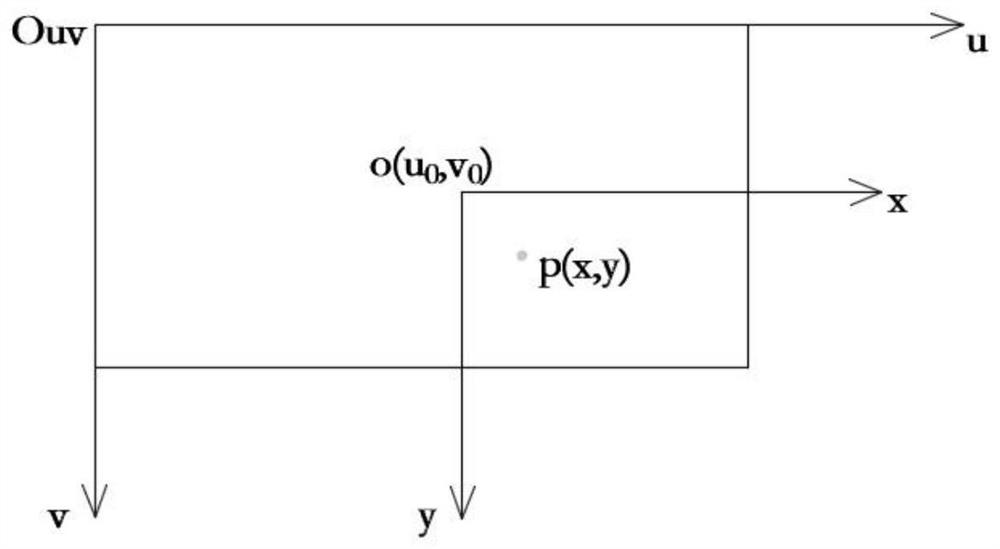

[0039] see Figure 1-Figure 5 , this implementation provides a ToF-based weld recognition method, including the following steps:

[0040] Step S1. Obtain the original weld image of the weldment to be processed through the camera based on ToF technology. The original weld image includes: amplitude image and depth image;

[0041] Specifically, the original weld seam image is the weld seam image before welding or after welding. In this embodiment, a camera based on ToF technology is used to directly capture and acquire, and the sensor in the camera based on ToF technology is an array type, so that The three-dimensional information of the target can be quickly obtained in the process of each frame of image acquisition; the sensor in the camera based on ToF technology can emit modulated infrared light, which diffusely reflects after encountering the weld seam, and the receiving end analyzes the emitted light and The phase difference or time difference of the received light can obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com