High-power four-quadrant converter fault-tolerant control method based on predictive control

A four-quadrant converter and fault-tolerant control technology, which is applied in the direction of converting AC power input to DC power output, converting AC power input to AC power output, and controlling electromechanical brakes, etc. It can solve the problem of decreased control accuracy and aggravated capacitor voltage imbalance To avoid personal safety accidents and huge economic losses, improve reliability and stability, avoid secondary failures and reduce control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

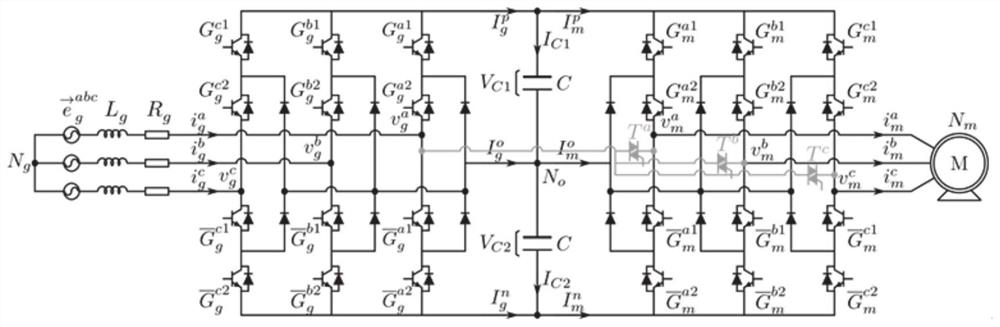

[0045] This embodiment proposes a bridge arm multiplexing fault-tolerant control circuit for a three-level neutral point clamped (3L NPC) back-to-back converter system, which is applied to a three-level neutral point clamped back-to-back converter, and the three The faulty bridge arm of the level midpoint clamped back-to-back converter is connected to the multiplexed bridge arm through a bidirectional thyristor.

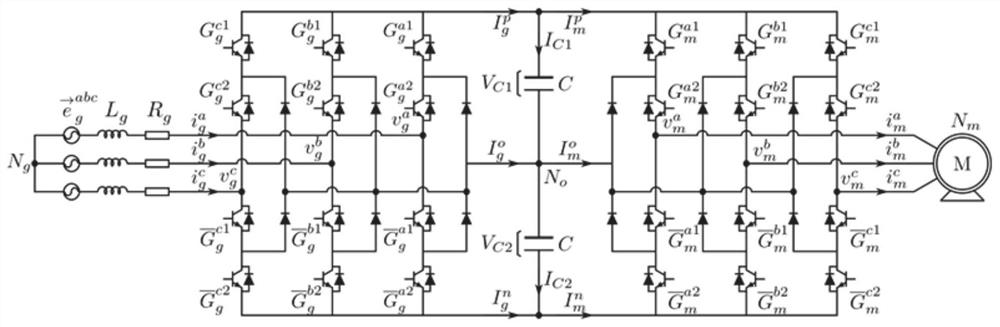

[0046] 3L NPC back-to-back converter model such as figure 1 As shown, it is composed of six-phase bridge arms, DC bus and filter. Each phase bridge arm is composed of four switching tubes and two anti-parallel diodes. Three levels can be output by giving different gate signals, and the DC bus is Consists of two capacitors with the same capacitance. The back-to-back converter can be divided into the grid side and the motor side as a whole. The structure of the grid side is that the DC bus is connected to the three-phase power supply through the active front-end recti...

Embodiment 2

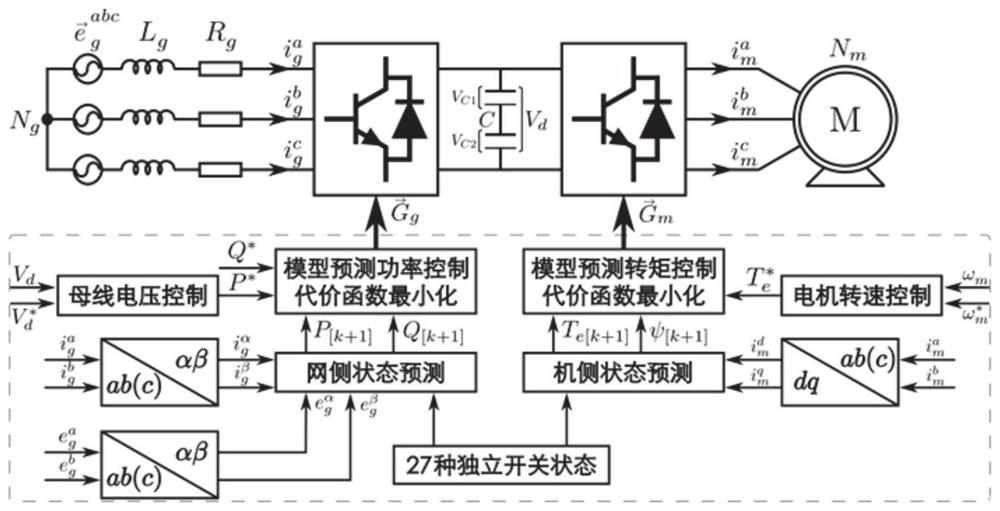

[0058] Embodiment 2 of the present disclosure provides a predictive control-based fault-tolerant control method for a high-power four-quadrant converter, which is applied to a three-level neutral-point clamped back-to-back converter, including the following process:

[0059] Obtain the parameter data of the converter after the faulty bridge arm and the multiplexed bridge arm are connected through the bidirectional thyristor;

[0060] Block the switching signal of the faulty bridge arm, and reorganize the switching state of the converter according to the obtained parameter data;

[0061] Traversing all combined switch states, predicting the system state at a certain moment in the future;

[0062] The optimal combined switch state is obtained with the goal of minimizing the weighted sum of the network-side cost function and the machine-side cost function;

[0063] Converter control is performed according to the optimal combination of switching states.

[0064] For the detailed...

Embodiment 3

[0066] Embodiment 3 of the present disclosure provides a predictive control-based high-power four-quadrant converter fault-tolerant control system, which is applied to a three-level neutral-point clamped back-to-back converter, including:

[0067] The data acquisition module is configured to: acquire the parameter data of the converter after the faulty bridge arm and the multiplexed bridge arm are connected through the bidirectional thyristor;

[0068] The switching state reorganization module is configured to: block the switching signal of the faulty bridge arm, and reorganize the switching state of the converter according to the obtained parameter data;

[0069] The state quantity prediction module is configured to: traverse all combined switch states, and predict the system state quantity at a certain moment in the future;

[0070] The optimal switch state acquisition module is configured to: take the minimum weighted sum of the network-side cost function and the machine-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com