Twelve-phase three-level H-bridge direct current side cascade propulsion frequency converter and capacitor voltage balance control method

A capacitor voltage, three-level technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the problem of difficult to meet the adaptability requirements of large-capacity inverters and other problems, to achieve the effect of high adaptability, strong inheritance, and simple main circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

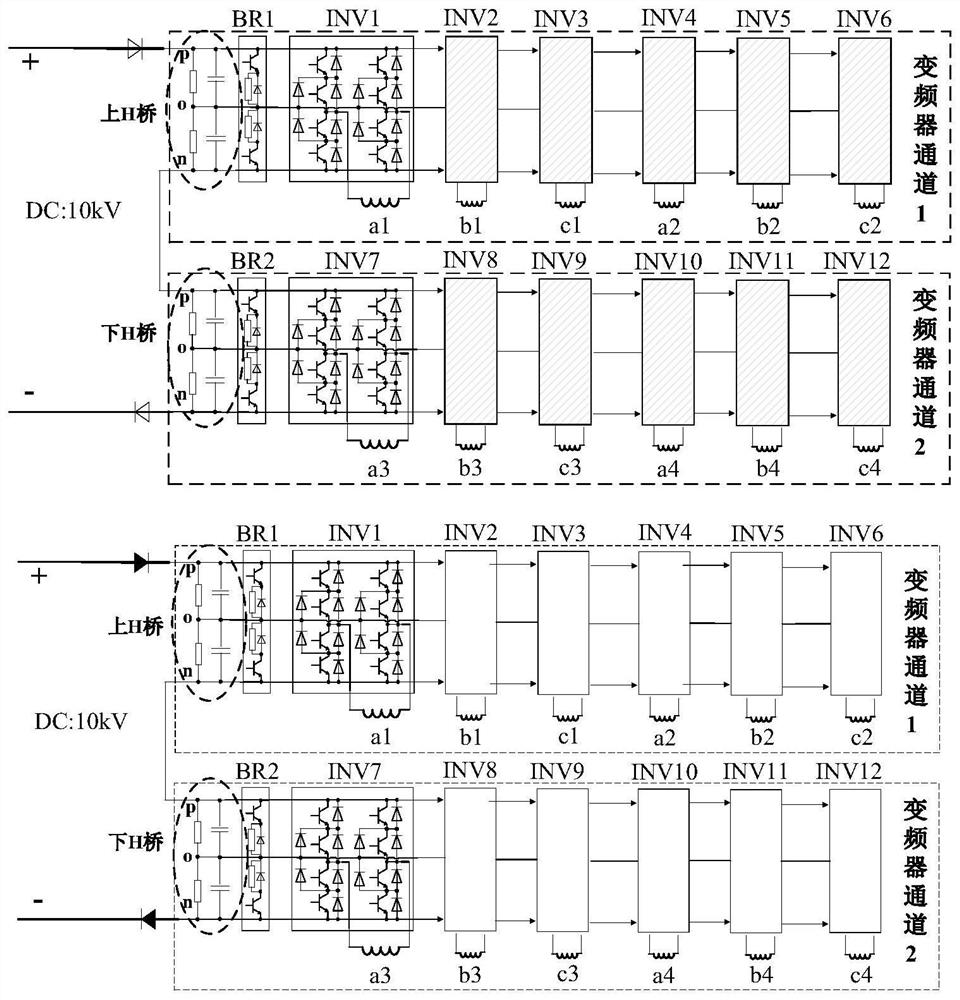

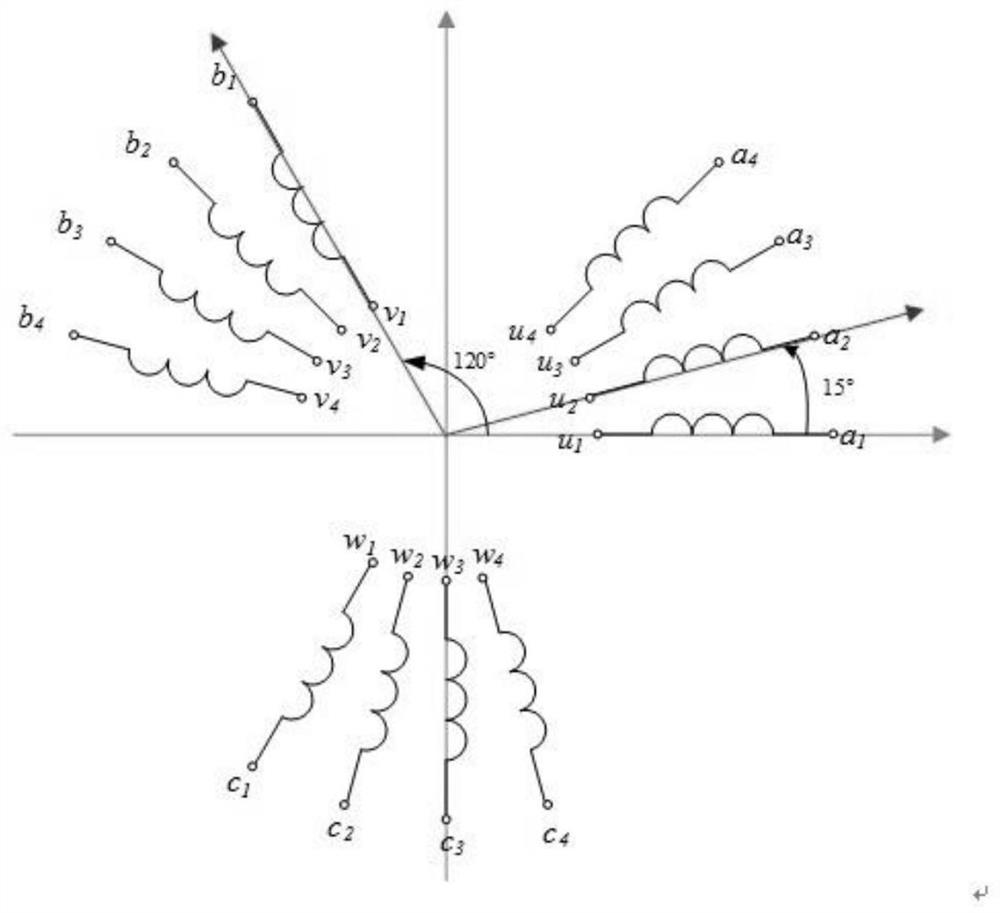

[0041] like figure 1The main circuit topology of the 12-phase three-level H-bridge DC-side cascaded propulsion inverter of the present invention is shown in the figure. A check diode is set at the positive stage of the DC input, and a check diode is set at the negative stage of the DC input for the propulsion inverter at the lower end of the cascade. Except for the check diode, the other electrics and structures are completely the same. There are mainly six three-level H-bridge inverters. unit, a braking unit, etc., the number of phases of the drive inverter and the twelve-phase open-winding motor are matched and designed (such as figure 2 shown).

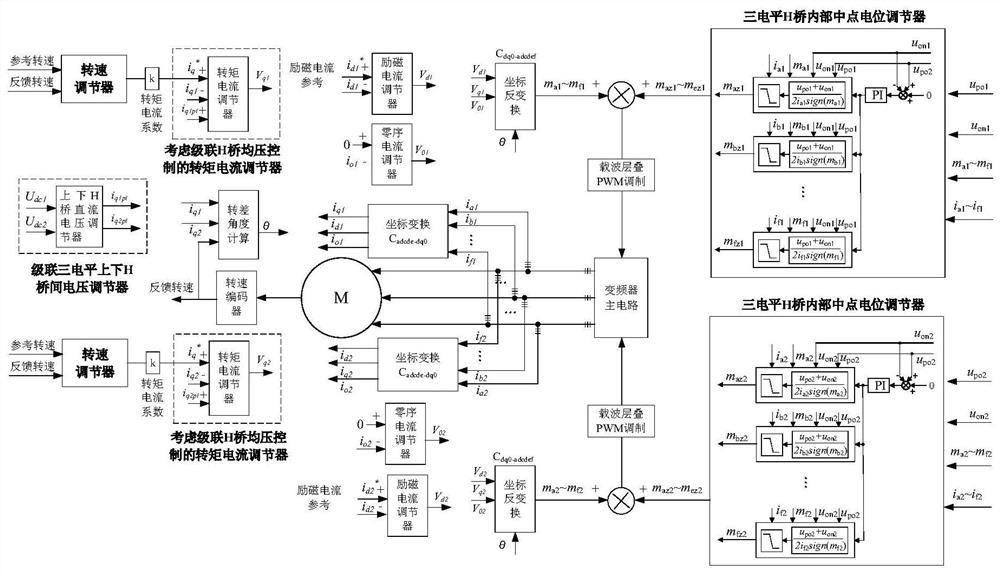

[0042] The capacitor-voltage equalization control of the DC-side cascaded propulsion inverter of the twelve-phase three-level H-bridge of the present invention includes four regulators, na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com