Double-screw extrusion type compound nutrition fertilizer granulator

A technology of double-screw extrusion and nutrient fertilizer, applied in the direction of extrusion and granulation of raw materials, can solve the problems of inconvenient rapid centralized collection of compound nutrient fertilizer granules, inability to effectively control granulation uniformity and granulation quality, etc. The effect of centralized collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

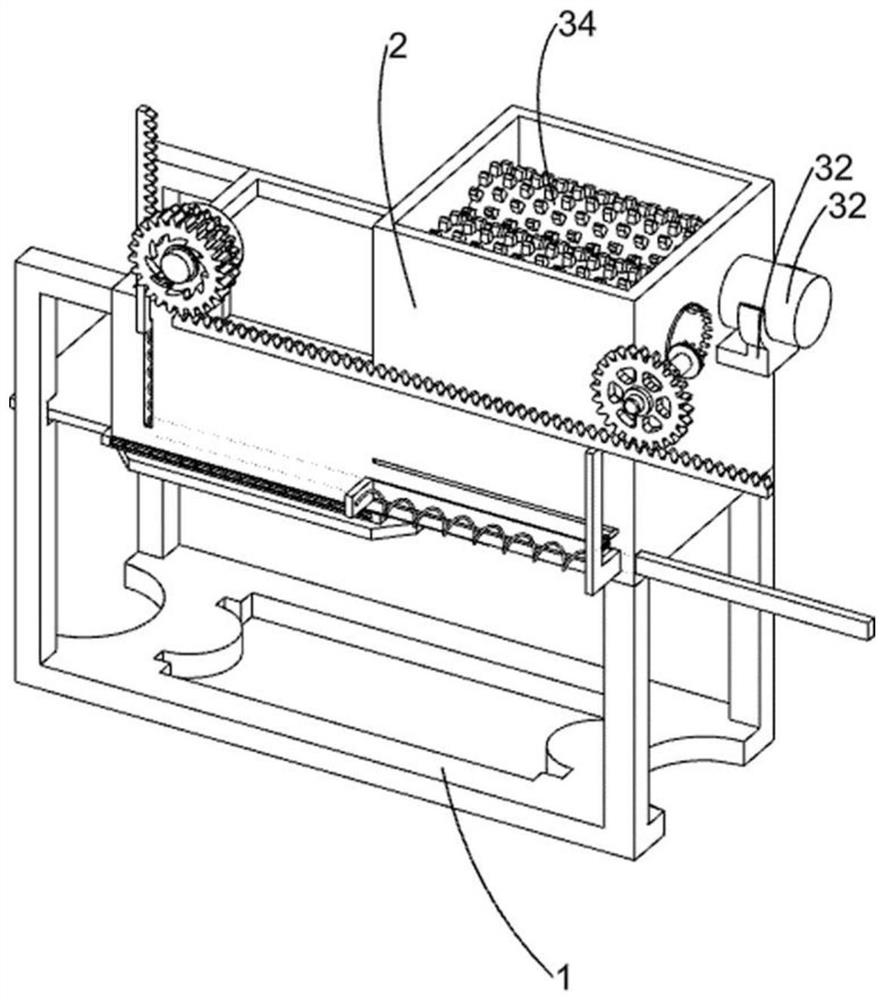

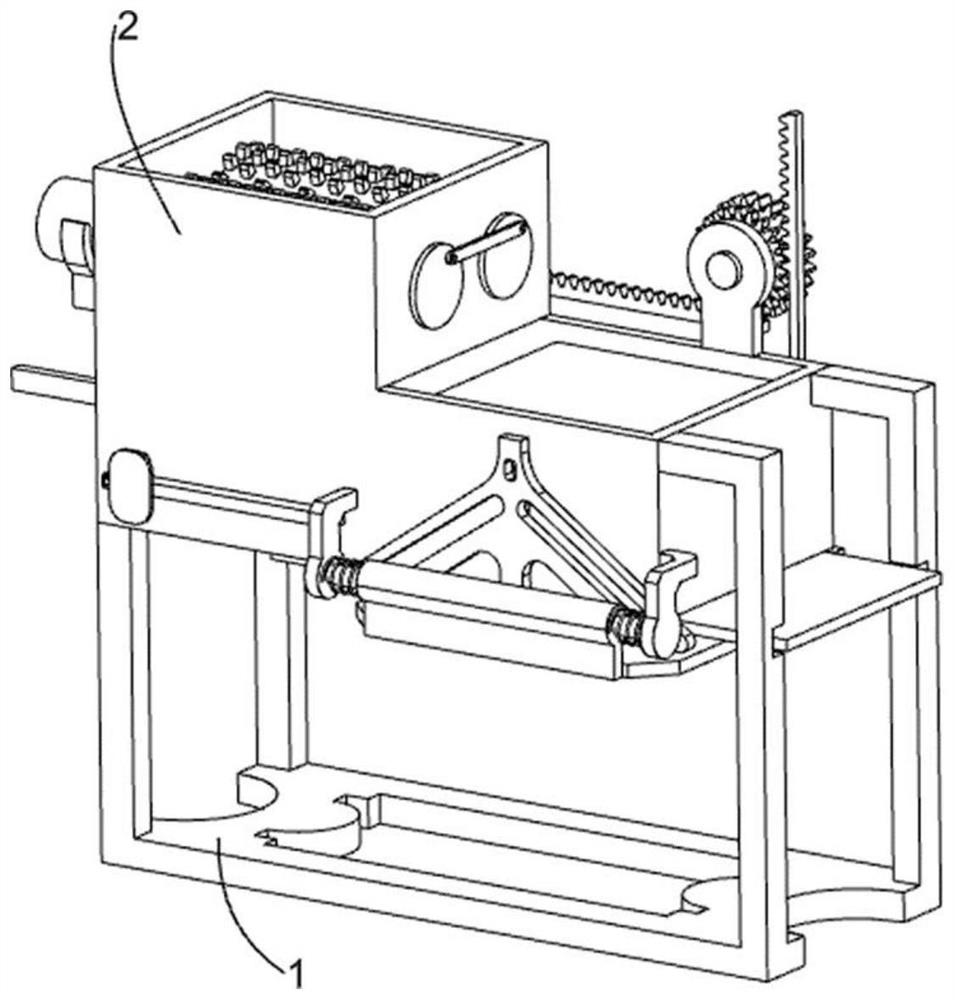

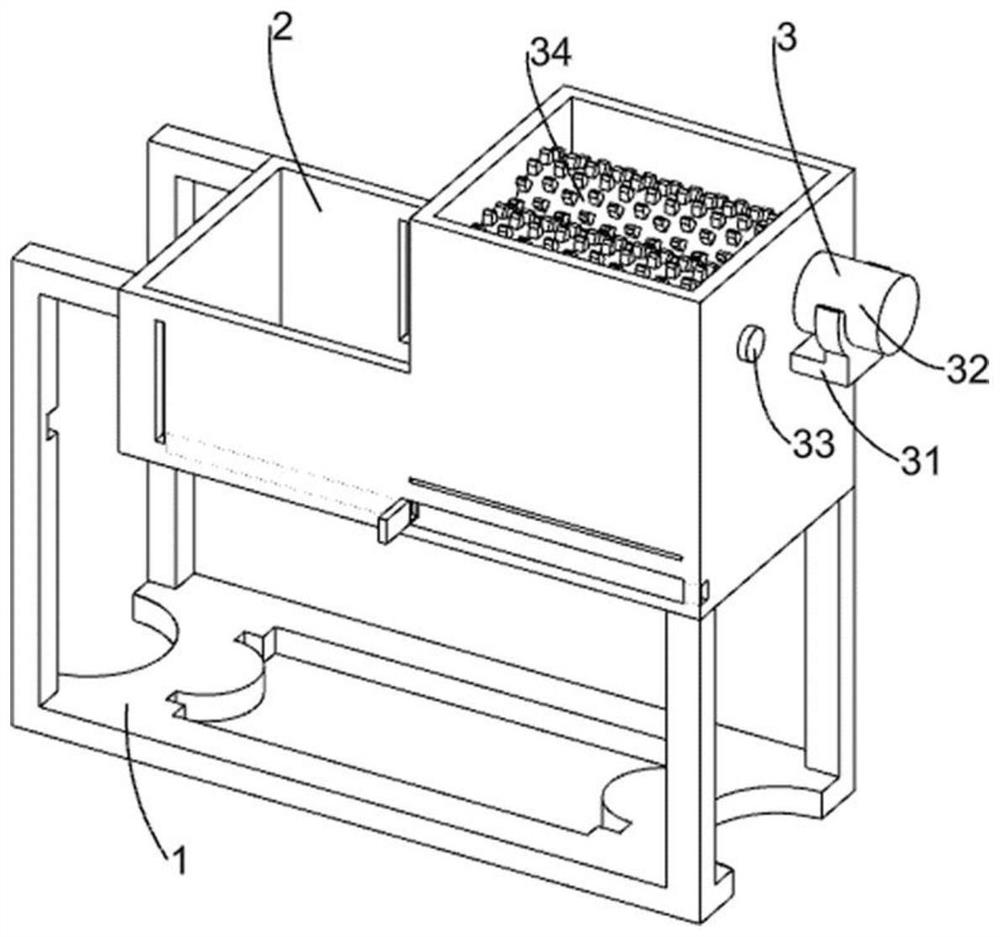

[0032] A kind of twin-screw extruding compound nutrient fertilizer granulator, such as Figure 1-3 As shown, it includes a bottom plate 1, a special-shaped tank 2, a rotary pressing mechanism 3, a front pushing mechanism 4, a pressing mechanism 5 and a granulation mechanism 6. The bottom plate 1 is connected with a special-shaped tank 2, and the special-shaped tank 2 is A rotary pressing mechanism 3 is provided, and the rotary pressing mechanism 3 is used to press down the compound nutritional fertilizer raw material onto the special-shaped tank 2, and the special-shaped tank 2 is provided with a front pushing mechanism 4, which is used to The compound nutritional fertilizer raw material is evenly pushed onto the perforated plate 511, and the side of the special-shaped tank 2 is provided with a pressing mechanism 5, which is used to extrude the compound nutritional fertilizer raw material from the perforated plate 511. 2. A granulation mechanism 6 is provided on one side, and ...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 4-12 As shown, the rotary pressing mechanism 3 includes a motor frame 31, a servo motor 32, a rotating shaft 33, a rolling barrel 34, a disk 35 and a connecting rod 36, and the special-shaped tank 2 is welded with a motor frame 31, and on the motor frame 31 A servo motor 32 is fixedly installed, and a pair of rotating shafts 33 are connected through bearings on the special-shaped tank 2, wherein a rotating shaft 33 is connected with the servo motor 32, and a rolling barrel 34 is fixedly connected to the rotating shaft 33, which is used for the rolling barrel 34. For extruding the compound nutritional fertilizer raw material, two rolling barrels 34 cooperate with each other, a disc 35 is connected on the rotating shaft 1 33, and a connecting rod 36 is movably connected between the two discs 35 .

[0035]The front pusher mechanism 4 includes missing toothed disc 41, rotating shaft seat 42, full toothed disc 43, gear one 44, speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com