Drying facility for abandoned animal carcasses

A technology for drying equipment and animal carcasses, applied in the field of drying equipment, can solve the problems of high energy consumption, decreased processing efficiency, long processing time, etc., and achieve the effect of reducing the cost of degreasing and facilitating storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

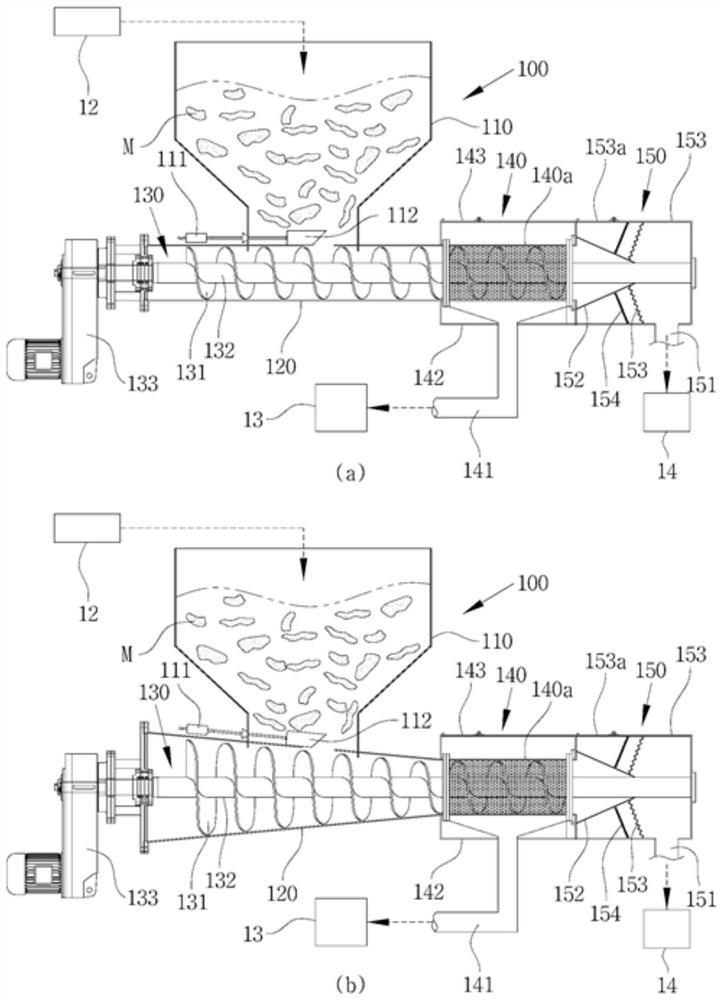

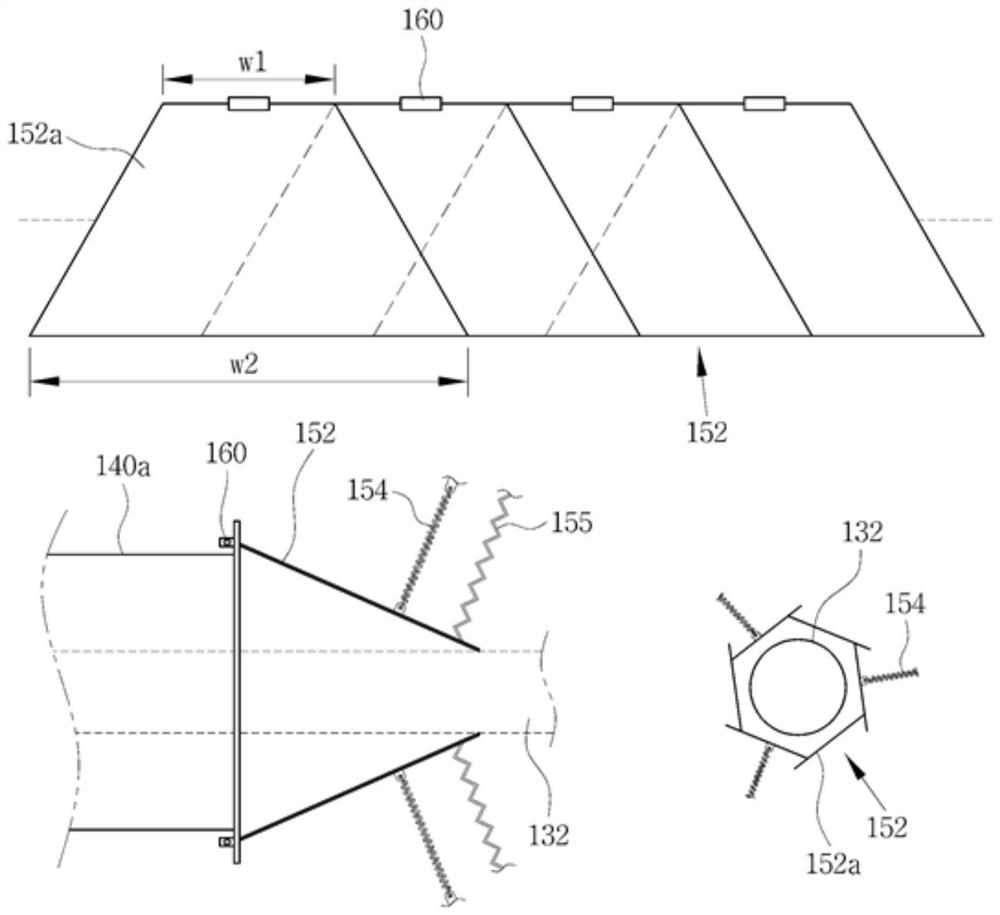

[0063] Next, a preferred embodiment of the present invention will be described in detail with reference to the drawings. The description is to make it easy to operate in order to make technicians in the art.

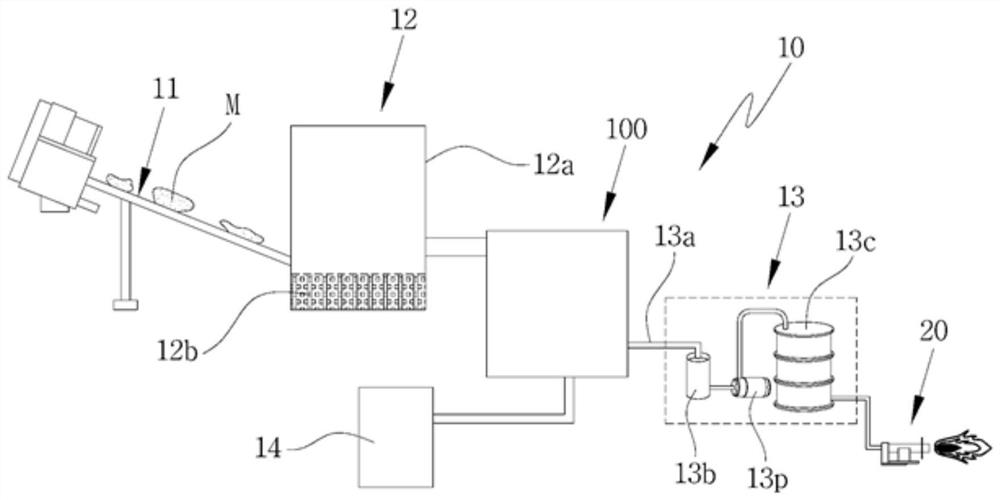

[0064] like Figure 1 to 9 As shown, a drying device 10 of a waste animal body according to the present invention includes:

[0065] The conveyor belt transfer unit 11 is used to transmit a waste of a slaughter (including the discarded animal body) of cattle, pig or poultry;

[0066] The heating unit 12 is used to heat the slaughtered waste through the conveyor belt conveying unit 11 by high temperature heating;

[0067] The degreasing unit 100 is used to accommodate the slaughtering waste by the heating unit 12, and is separated into waste grease and the slaughter by-product is discharged;

[0068] The oil storage unit 13 is provided with the degreasing unit 100 for storing waste grease produced by the degreasing unit 100;

[0069] The drying unit 14 is connected to the degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com