Aerated concrete plate with prearranged pipeline, preparation method and construction method

A technology of aerated concrete and pipelines, which is applied in the direction of clay preparation devices, manufacturing tools, chemical instruments and methods, etc. It can solve the problems of low efficiency of hydropower pipelines and affect the structural strength of autoclaved aerated concrete slabs, and achieve high support And tightness, high consistency, avoiding the effect of plastering and hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

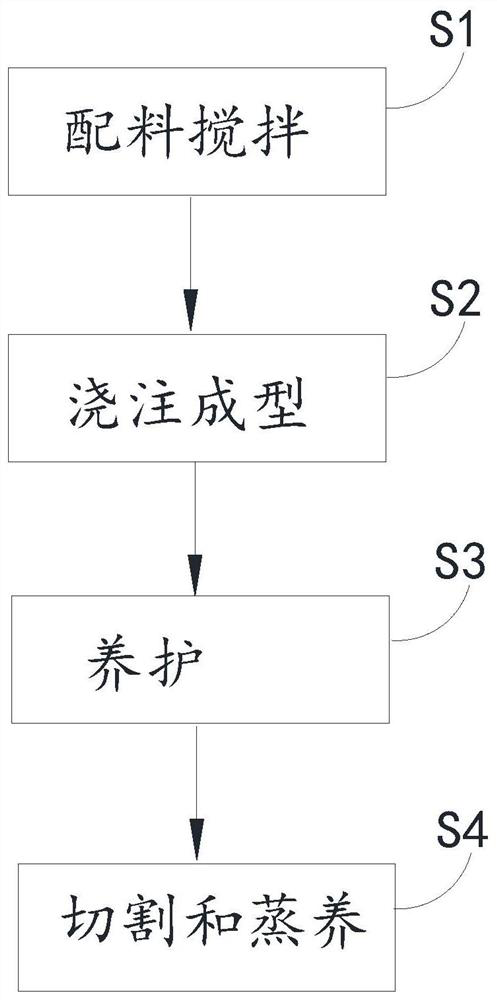

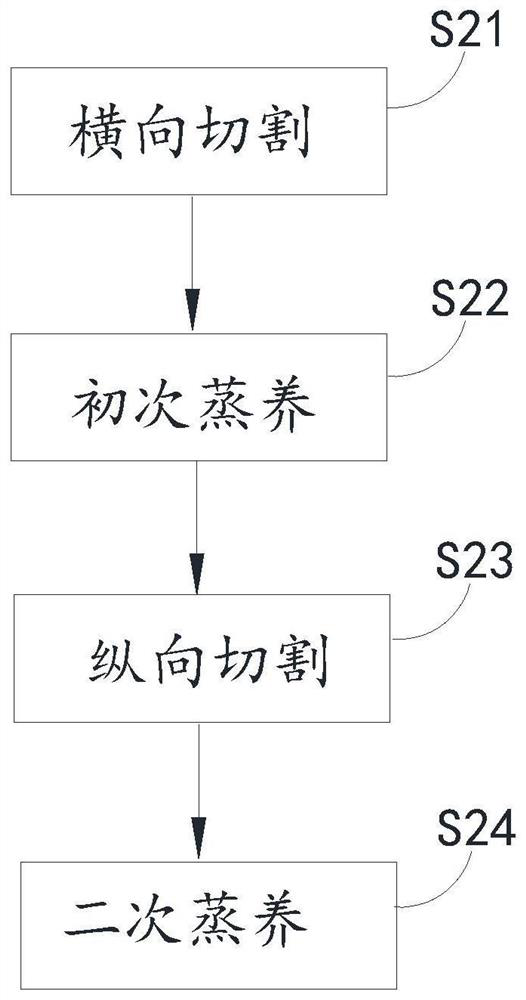

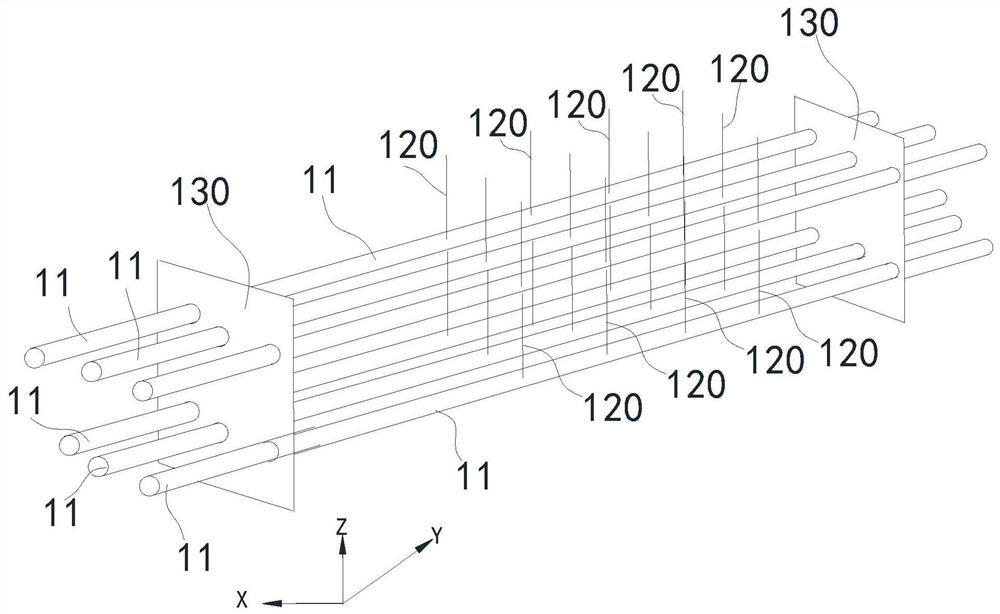

[0063] see Figure 1 to Figure 9 , this embodiment provides a method for preparing an aerated concrete slab with pre-installed pipes. The method for preparing the aerated concrete slab with preset pipes can pre-set pipes in the autoclaved aerated concrete slab during production of the autoclaved aerated concrete slab, and the pipes can be used for water supply pipes or circuit wiring pipes. Therefore, when the autoclaved aerated concrete slab is used to build the wall, it is not necessary to make grooves on the wall before or after the wall is built. Such as figure 1 As shown, the preparation method of the aerated concrete slab with pre-installed pipeline comprises the following steps:

[0064] S1. Stirring of ingredients: uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com