Spherical tooth track running structure and tracked micro-electric vehicle

A driving structure and spherical tooth technology, applied in the field of transmission, can solve the problems of slow running, lack of drag force, and affecting tourists' sightseeing experience, etc., and achieve the effect of reducing manufacturing cost and making it easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

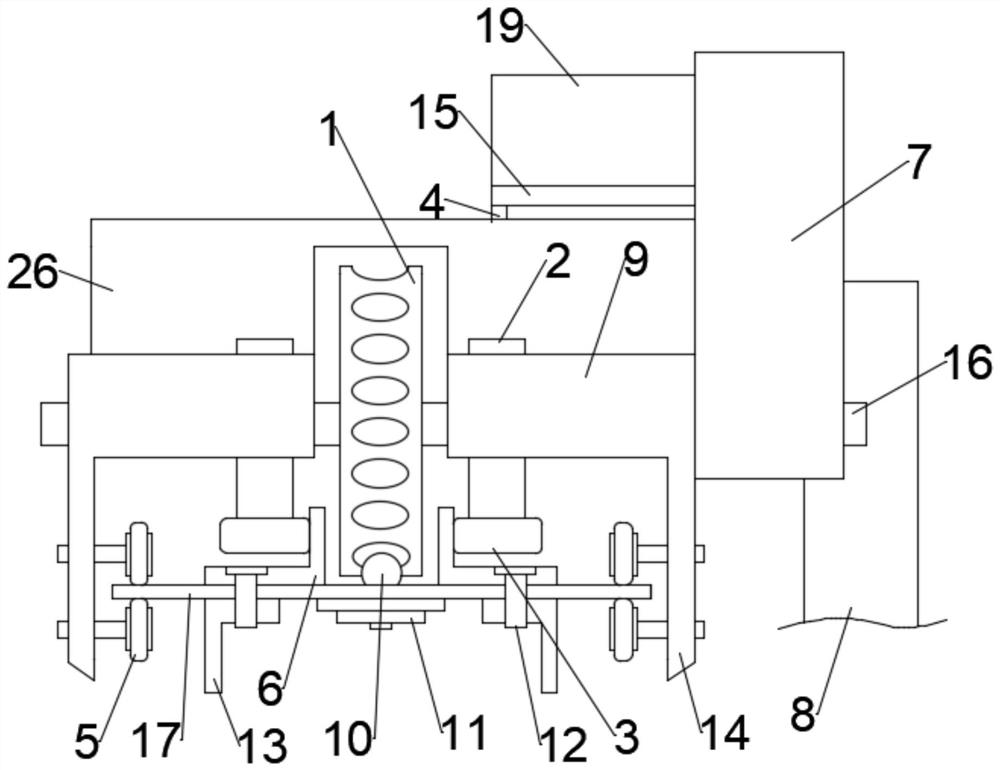

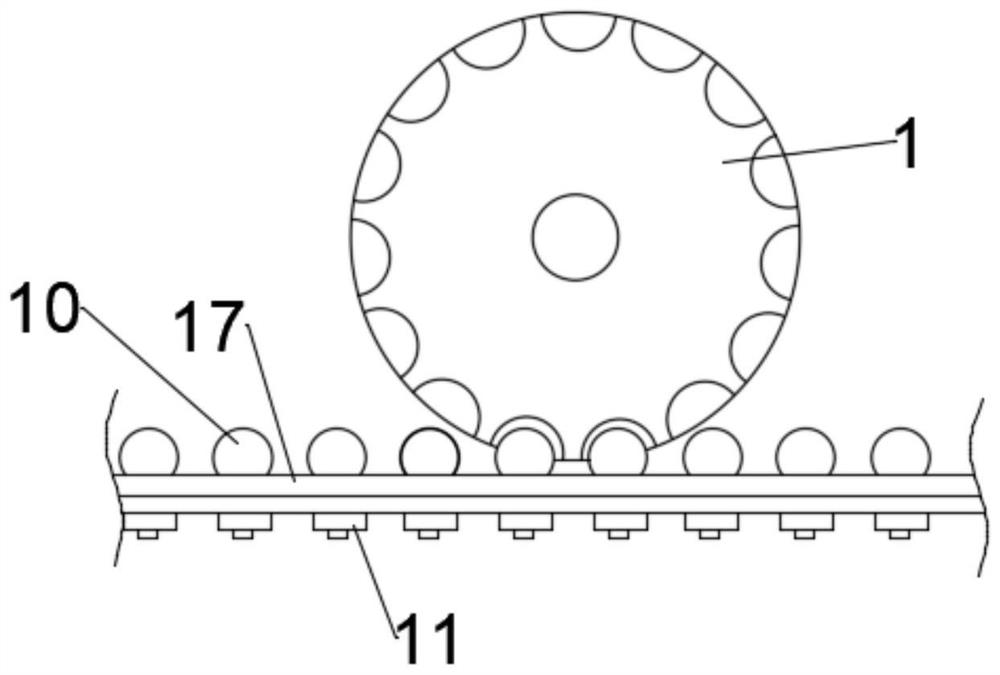

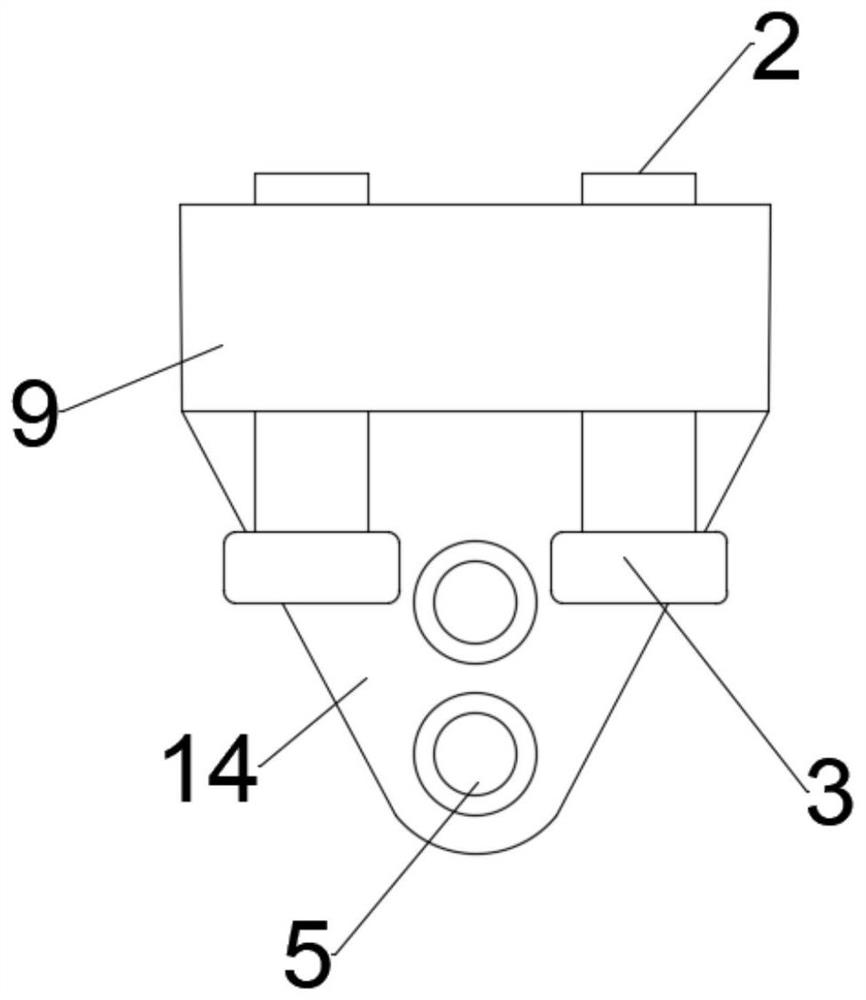

[0040] like Figure 1-5 As shown, the present embodiment provides a spherical tooth track driving structure, including: a track 17, a concave tooth drive gear 1, a guide assembly and a locking rail assembly.

[0041] The rail 17 is provided with a guide rail 6 arranged along the length direction of the rail 17 and a plurality of spherical teeth 10 arranged at equal intervals. The concave tooth drive gear 1 is provided with concave teeth adapted to the spherical teeth 10 . The concave-tooth drive gear 1 is rotatably connected to the guide assembly, and one end of the guide assembly is connected to the guide rail 6. Through the cooperation between the guide assembly and the guide rail 6, the concave-tooth drive gear 1 is kept rotating along the laying direction of the spherical teeth 10. The concave-tooth drive gear 1 When rotating, the spherical tooth 10 meshes with the concave tooth. One end of the lock rail assembly is connected with the guide assembly, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com