Biodegradable material and preparation method thereof

A technology for degrading materials and degrading plastics, applied in the field of degradable materials, can solve the problems of complex preparation methods and high cost of degradable materials, and achieve the effect of simple preparation methods and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

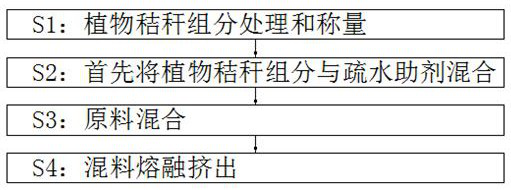

[0028] refer to figure 1 , a biodegradable material, including the following important components: 40 parts of plant straw components, 6 parts of modified starch, 3 parts of degradable plastic resin, 3 parts of polystyrene, 2 parts of polyglycolic acid, 1.2 parts of toughening agent, 3 parts of hydrophobic additive, 2 parts of liquid viscous agent, 0.3 part of antioxidant, 0.3 part of preservative, straw components include corn straw powder, wheat straw powder, rice straw powder and soybean straw powder, corn straw powder, wheat straw The mass ratio of rice straw powder, rice straw powder and soybean straw powder is 1:1:1:1.

[0029] The present invention also proposes a method for preparing biodegradable materials, including the following preparation methods:

[0030] S1: Processing and weighing of plant straw components;

[0031] S2: first mixing the plant straw component with the hydrophobic additive;

[0032] S3: raw material mixing;

[0033] S4: Mixed material melt ex...

Embodiment 2

[0044] refer to figure 1 , a biodegradable material, including the following important components: 47 parts of plant straw components, 7 parts of modified starch, 4.5 parts of degradable plastic resin, 4.5 parts of polystyrene, 3 parts of polyglycolic acid, 1.9 parts of toughening agent, 4.5 parts of hydrophobic additive, 3.5 parts of liquid viscous agent, 0.45 part of antioxidant, 0.45 part of preservative, straw components include corn straw powder, wheat straw powder, rice straw powder and soybean straw powder, corn straw powder, wheat straw The mass ratio of rice straw powder, rice straw powder and soybean straw powder is 1:1:1:1.

[0045] The present invention also proposes a method for preparing biodegradable materials, including the following preparation methods:

[0046] S1: Processing and weighing of plant straw components;

[0047] S2: first mixing the plant straw component with the hydrophobic additive;

[0048] S3: raw material mixing;

[0049] S4: Mixed materi...

Embodiment 3

[0060] refer to figure 1 , a biodegradable material, including the following important components: 50 parts of plant straw components, 8 parts of modified starch, 6 parts of degradable plastic resin, 6 parts of polystyrene, 4 parts of polyglycolic acid, 2.4 parts of toughening agent, 6 parts of hydrophobic additive, 5 parts of liquid viscous agent, 0.6 part of antioxidant, 0.6 part of preservative, straw components include corn straw powder, wheat straw powder, rice straw powder and soybean straw powder, corn straw powder, wheat straw The mass ratio of rice straw powder, rice straw powder and soybean straw powder is 1:1:1:1.

[0061] The present invention also proposes a method for preparing biodegradable materials, including the following preparation methods:

[0062] S1: Processing and weighing of plant straw components;

[0063] S2: first mixing the plant straw component with the hydrophobic additive;

[0064] S3: raw material mixing;

[0065] S4: Mixed material melt ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com