Non-woven fiber low-speed and high-yield random carding machine

A non-woven fiber and carding machine technology, applied in the field of carding machines, can solve the problems of unreasonable carding system design, unsuitable non-woven fibers, unreasonable card clothing design, etc., and achieves improved clutter effect, good clutter effect, and structure Design scientific and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

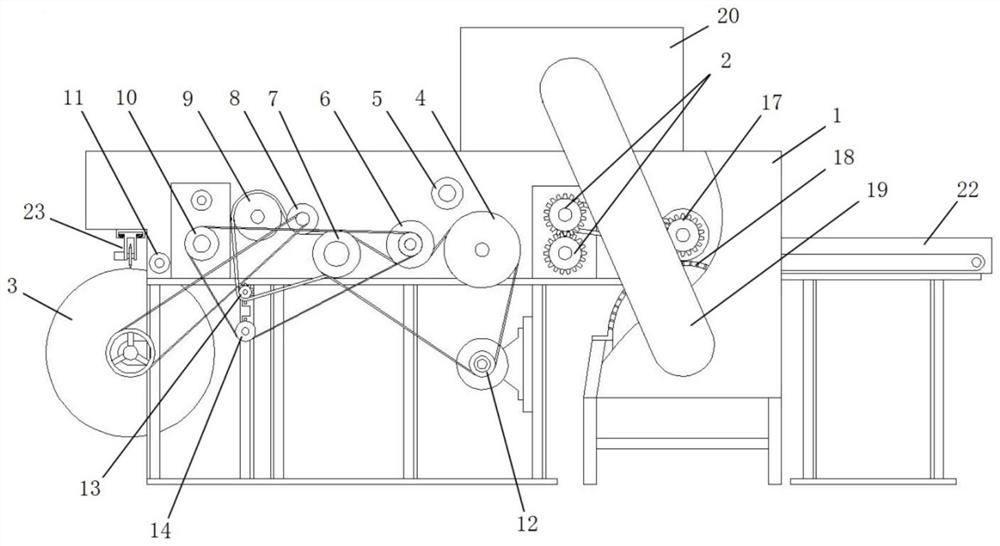

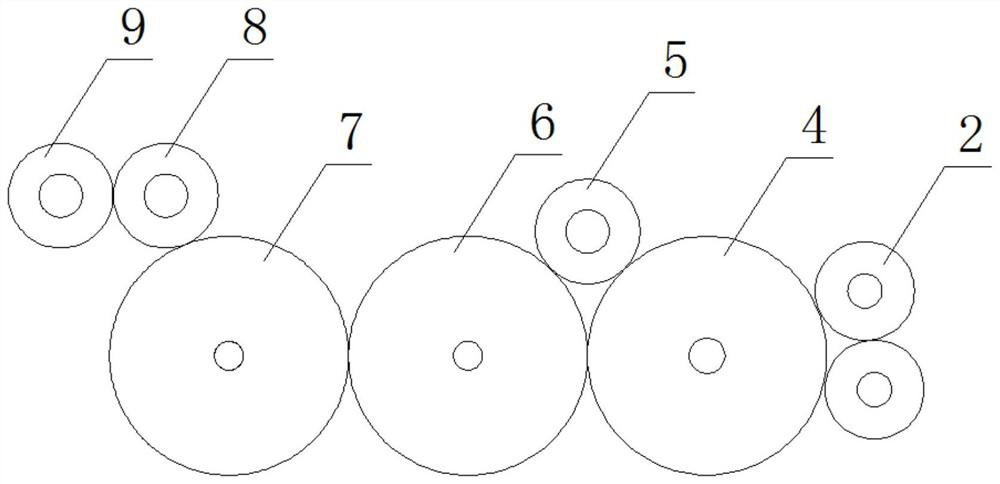

[0035] Such as figure 1 with figure 2 As shown, the present embodiment is a low-speed and high-yield messy carding machine for nonwoven fibers, comprising a frame 1, a group of feeding rollers 2 are provided at the front end of the frame 1, and a cotton roll 3 is provided at the rear end, and it is characterized in that: The frame 1 is located between the feeding roller 2 and the winding roller 3, and the part rotates from front to back to support the opening roller I4, the auxiliary opening roller 5, the opening roller II6, the doffer 7, the inner coagulation roller 8 and the outer coagulation roller 9.

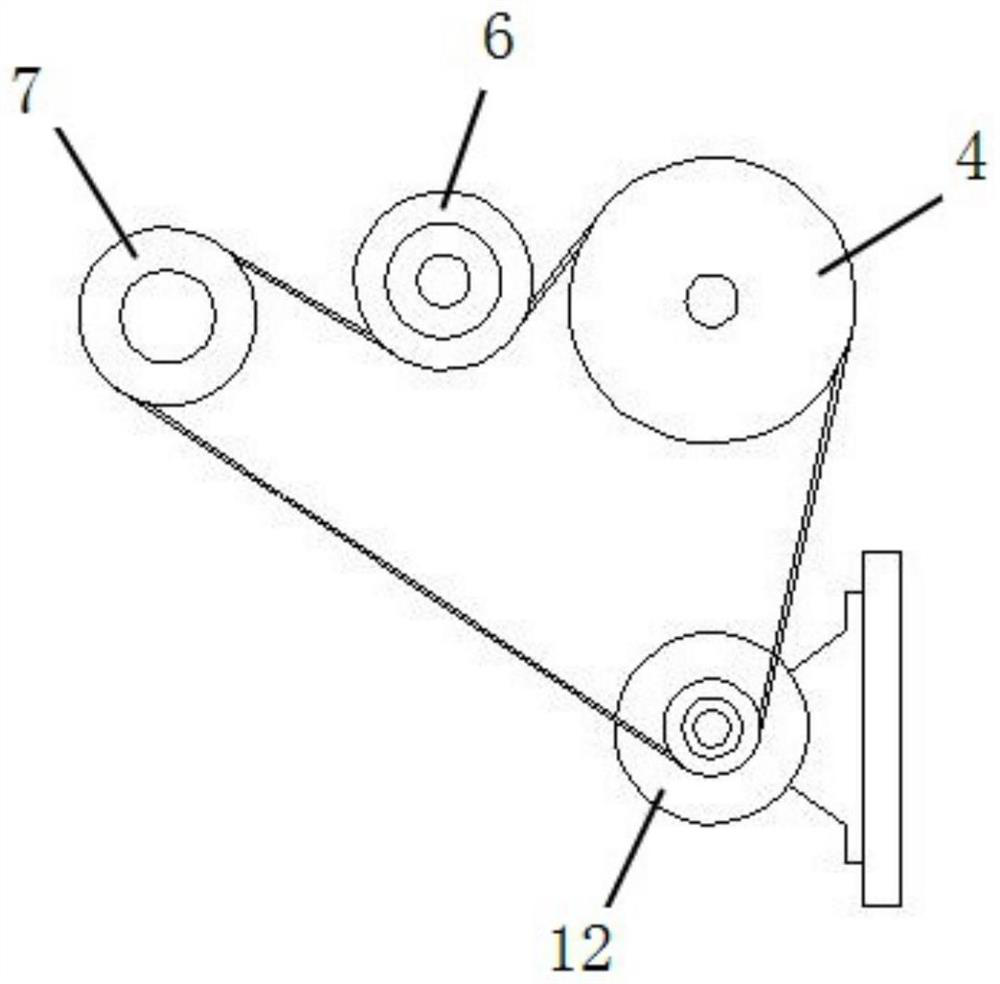

[0036] Such as image 3 As shown, the opening roller I4 and the opening roller II6 are connected to the rotating shaft of the first drive motor 12 through the first transmission belt, and the end of the doffer 7 is provided with a guide wheel for guiding the first transmission belt.

[0037] Such as Figure 4 As shown, the doffer 7 is driven to rotate by a pulley provid...

Embodiment 2

[0045] This embodiment is a low-speed and high-yield disorderly carding machine for nonwoven fibers, which includes a frame 1, a group of feeding rollers 2 are provided at the front end of the frame 1, and a winding roller 3 is provided at the rear end, and it is characterized in that: the frame 1 is located at The part between the feeding roller 2 and the winding roller 3 rotates from front to back to support the opening roller I4, the auxiliary opening roller 5, the opening roller II6, the doffer 7, the inner condensing roller 8 and the outer condensing roller 9. The opening roller I4 and the opening roller II6 are connected to the rotating shaft of the first driving motor 12 through the first transmission belt, the doffer 7 is driven to rotate by the second driving motor 15, and one end of the doffer 7 is connected to the inner condensed cotton through the second transmission belt. The roller 8 is connected by transmission, and the other end of the doffer 7 is connected by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com