Construction method for prefabricated superposed beams and slabs

A construction method and technology of laminated slabs, which are applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, girders, etc., and can solve the problem of easy cracking at the joints of laminated slabs or laminated beams problems, to achieve the effect of increasing the number of reusable times and saving the amount of templates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

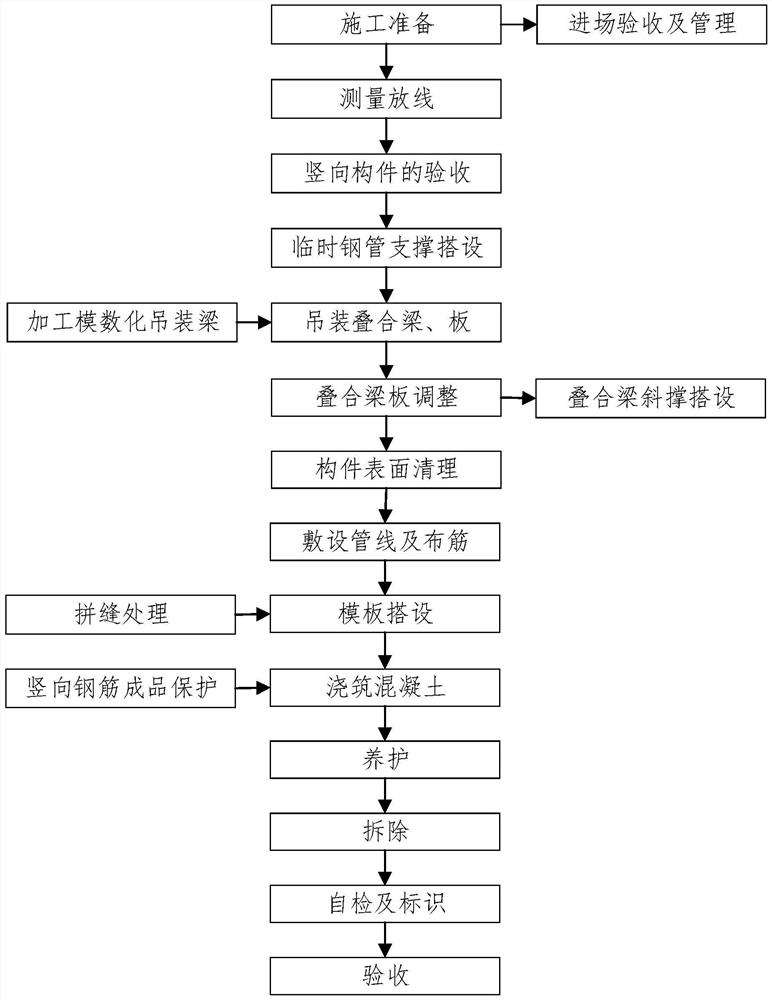

[0029] The embodiment of the present invention proposes a construction method for assembled composite beams and slabs:

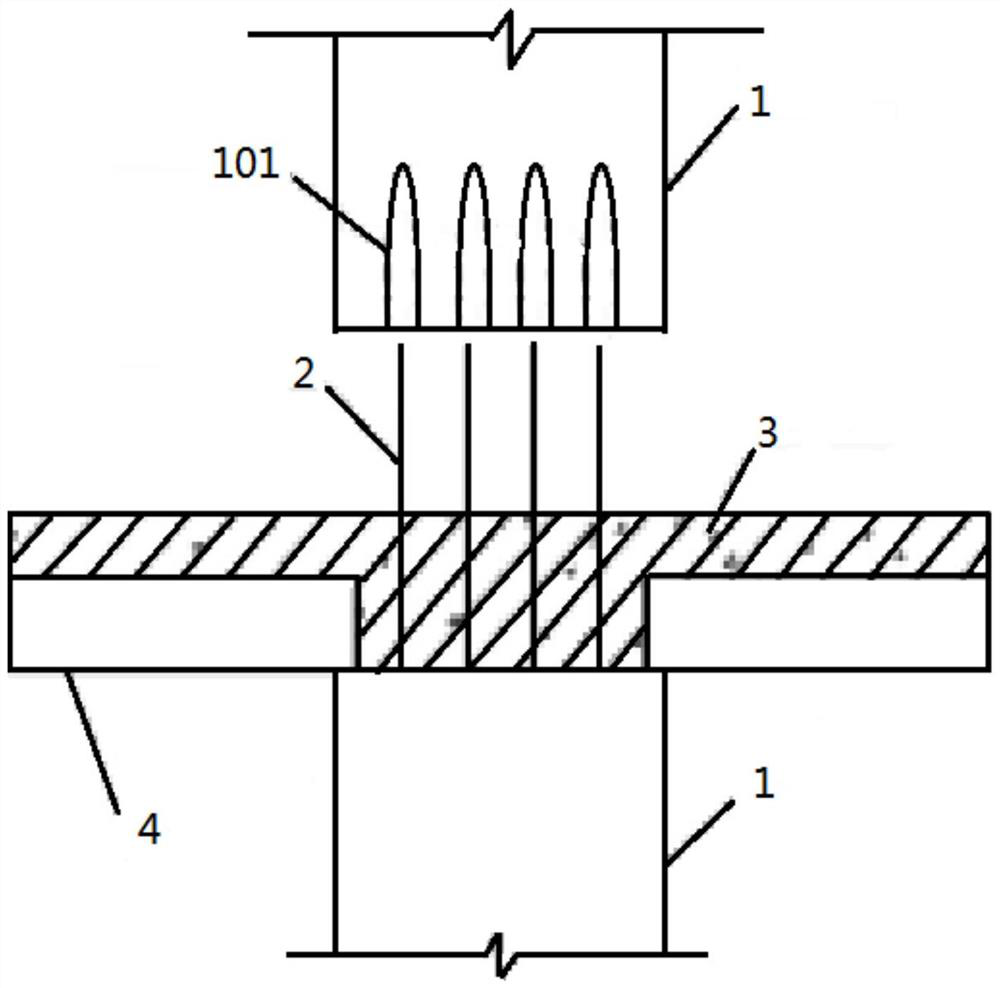

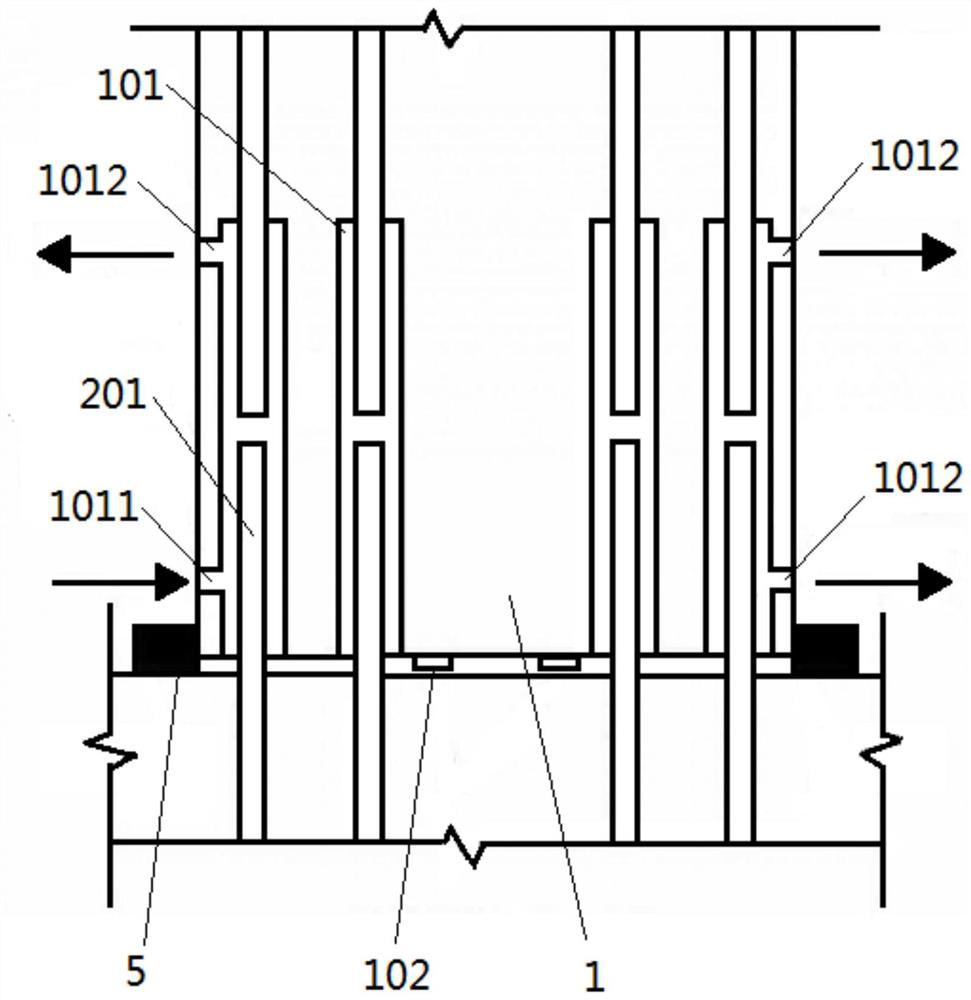

[0030] Such as Figure 1~4 shown, including:

[0031] Surveying and setting out, carrying out horizontal control setting out and elevation control setting out, arranging vertical control points and pilot elevation control points;

[0032] Put the temporary steel pipe support in place quickly, and use the laser level to quickly erect the temporary support before hoisting the laminated slab and laminated beam;

[0033] Hoist the laminated beams and laminated slabs in place, adjust and fix the laminated beams and laminated slabs;

[0034] Clean the surface of composite beams and composite slabs, and use grid cloth and expanded concrete to treat the joints and joints of composite slabs;

[0035] After the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com