Modularized fabricated kitchen wall panel

A prefabricated, wall panel technology, applied in special buildings, small buildings, building components, etc., can solve the problem of panel warping (thermal expansion, large thermal expansion and cold contraction, beauty joint block collapse, etc. problem, to achieve the effect of saving dosage and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

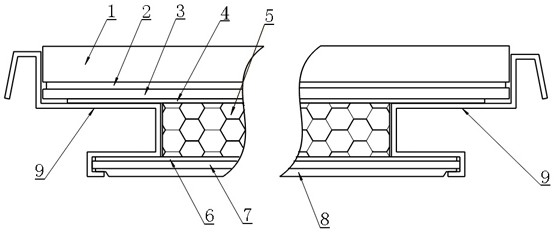

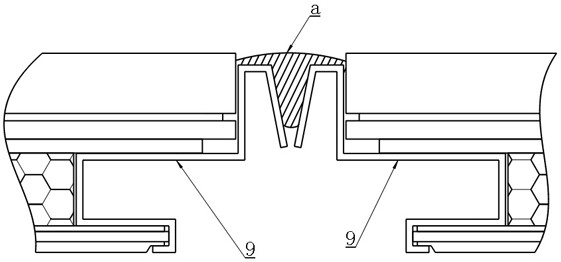

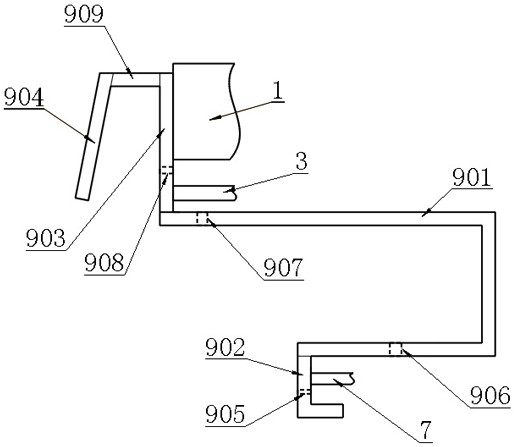

[0027] Example: as attached figure 1 , 2 and attached image 3 As shown, a modular assembled kitchen wall panel, which sequentially includes a decorative panel 1, a first adhesive layer 2, an outer steel plate 3, a second adhesive layer 4, a honeycomb core board 5, and a third adhesive layer from outside to inside. The junction layer 6, the inner steel plate 7, the fourth adhesive layer 8 for bonding the wall, and the outer steel plate 3 and the inner steel plate 7 are arranged between the inner steel plate 7 and passed through the honeycomb core plate 5. Concave way to intercept and accommodate excess glue support profile unit 9.

[0028] In this embodiment, the decorative panel 1 is an existing fireproof decorative panel or an antibacterial decorative panel, the outer steel plate 3 and the inner steel plate 7 are galvanized steel plates, and all four bonding layers are made of common plate The bonding is done by curing with glue, and it is sufficient to finally ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com