Three-degree-of-freedom hybrid bias magnetic bearing

A technology of degrees of freedom and magnetic bearings, applied in the direction of bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of non-adjustable bias magnetic flux, non-adjustable permanent magnetic flux, and low inherent rigidity, and achieve low design difficulty, The effect of high critical speed and power density and high suspension precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

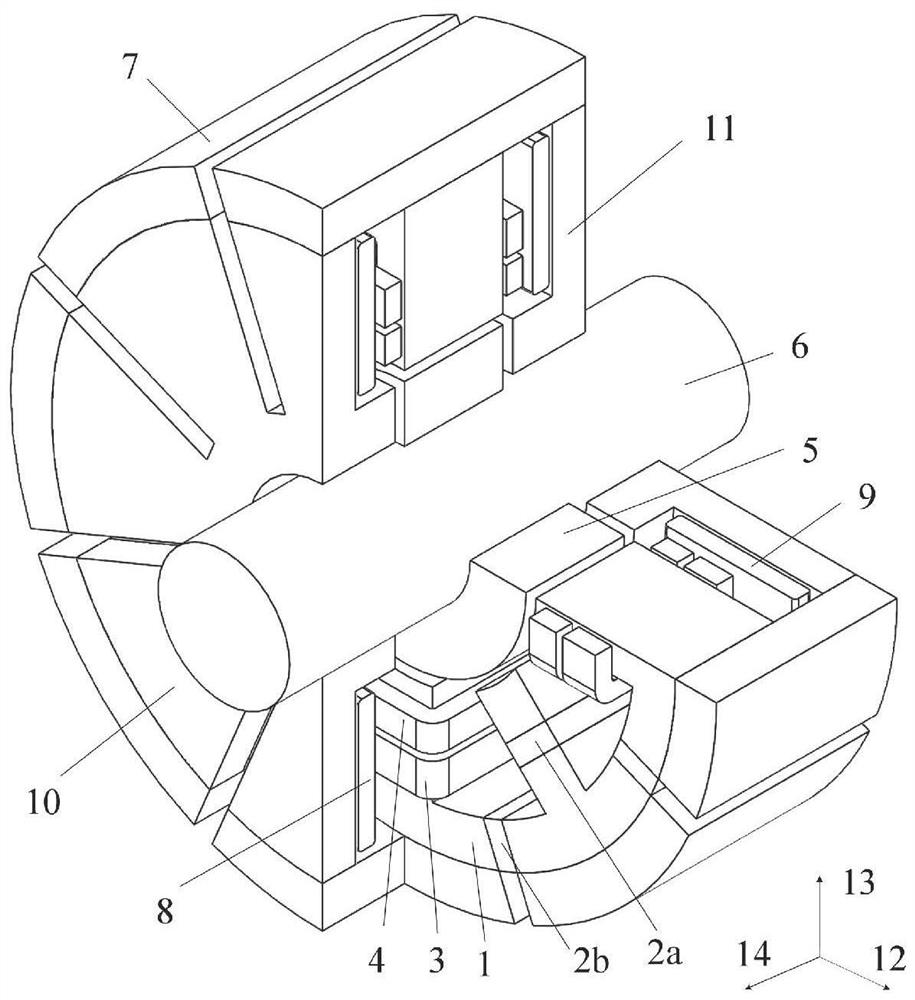

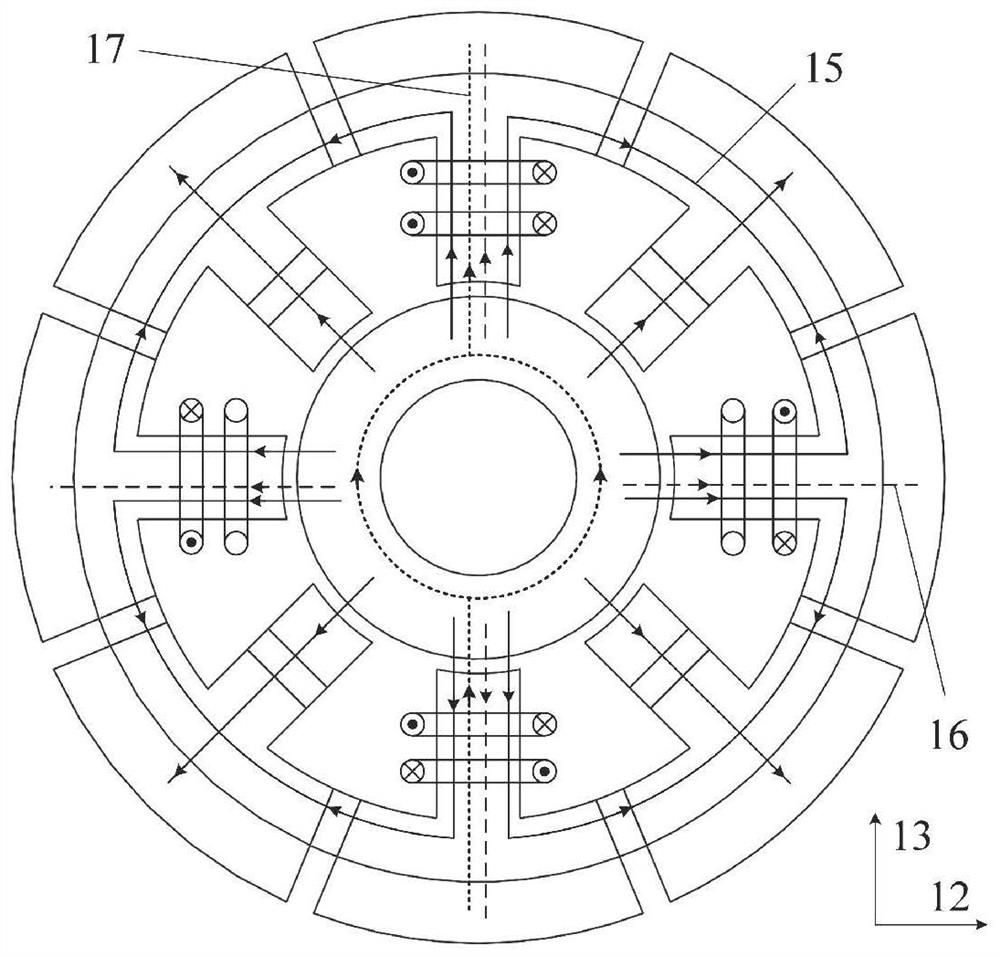

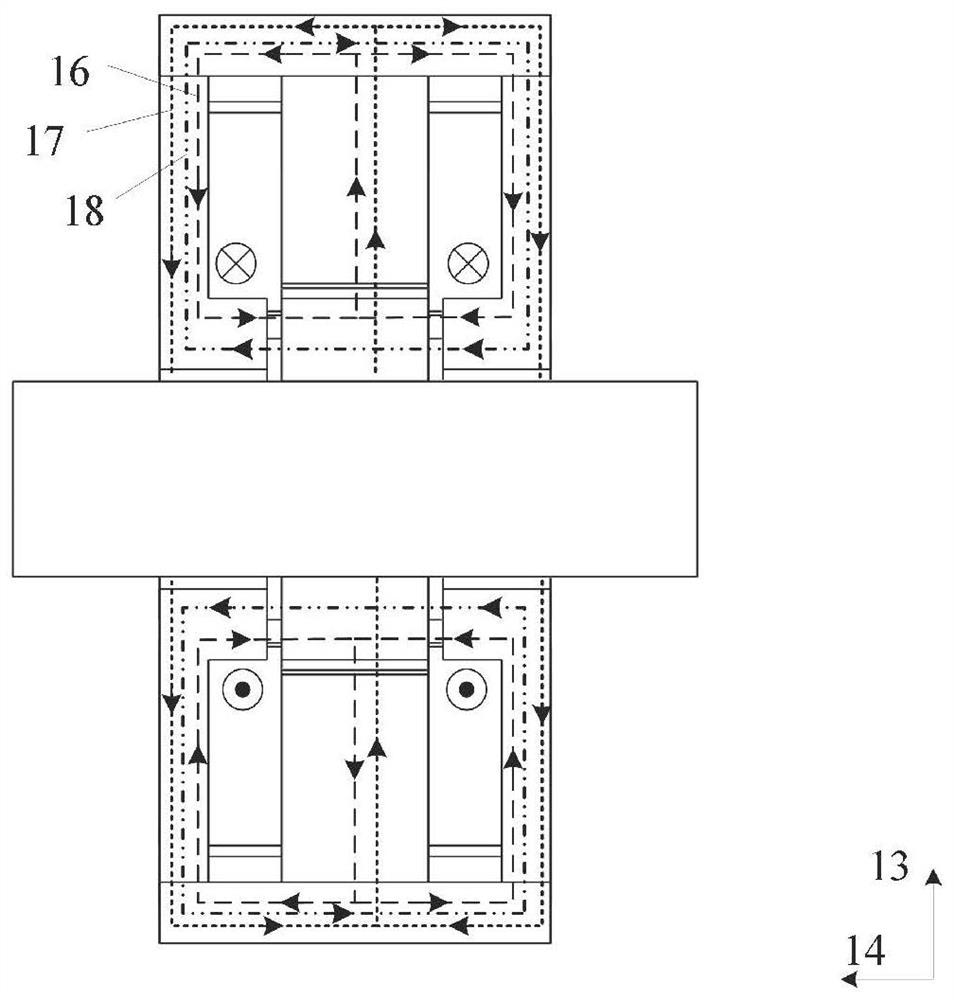

[0031] The technical scheme of a three-degree-of-freedom hybrid bias magnetic bearing of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0032] Such as figure 1 As shown, it is a three-dimensional structural schematic diagram of a three-degree-of-freedom hybrid bias magnetic bearing of the present invention, wherein, 1 is a radial force stator, 2a is a tooth permanent magnet, 2b is a yoke permanent magnet, 3 is a bias coil, and 4 is a radial force Suspension coil, 5 is the rotor, 6 is the rotating shaft, 7 is the magnetic yoke, 8 is the axial suspension coil Ⅰ, 9 is the axial suspension coil Ⅱ, 10 is the axial force stator Ⅰ, 11 is the axial force stator Ⅱ, 12 , 13, and 14 are the positive directions of the coordinate axes in the x, y, and z directions, respectively.

[0033]A three-degree-of-freedom hybrid bias magnetic bearing, including a radial force stator, a tooth permanent magnet, a yoke permanent magnet, a magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com