Residue weighing data analysis and correction method for kitchen waste treatment

A technology of food waste and correction method, which is applied in the field of food waste treatment residue weighing data analysis and correction, waste weighing data analysis and correction field, can solve the problems of theoretical waste total amount and measurement total amount error, etc., and achieve high scale Emphasis on accuracy, simple operation, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

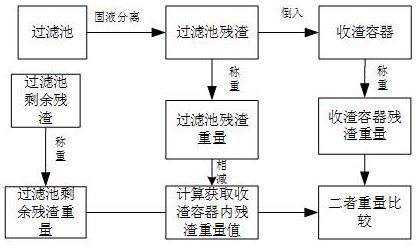

[0035] Embodiment: an intelligent detection and correction system, including a weight detection unit that detects the weight of the residue in the filter tank and the weight of the residual residue in the filter tank, a signal conversion unit, a control unit, and a computer control system; the signal conversion unit converts the electrical signal measured by the weight detection unit Convert it into a digital signal recognizable by the computer and send it to the computer control system, and the computer control system will feed back the error existing after processing to the system for correction.

[0036] The weight detection unit includes four independent pressure sensors installed around the lower end of the filter tank; the signal detection unit converts the transmitted pressure electrical signal into a digital signal that can be recognized by the computer; the control unit processes the data.

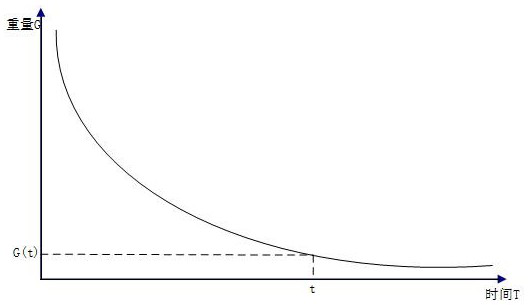

[0037] When the four independent pressure sensors measure the weight of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com