Intelligent uniform spraying device for flame retardant production and flame retardant production method

The technology of spraying device and flame retardant is applied in the direction of spraying device, liquid spraying device, and device for coating liquid on the surface, etc., which can solve the problems of affecting the flame-retardant effect of flame-retardant sound-absorbing panels, inconvenient spraying and unevenness, etc. Achieve the effect of improving stability, preventing waste and ensuring efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

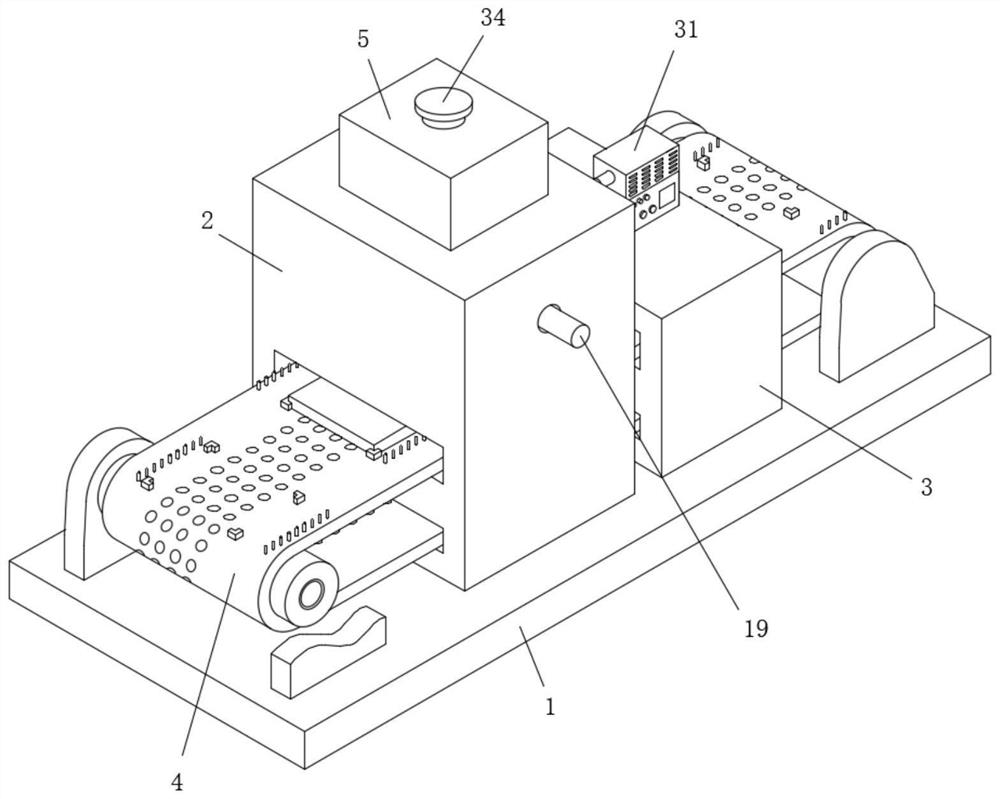

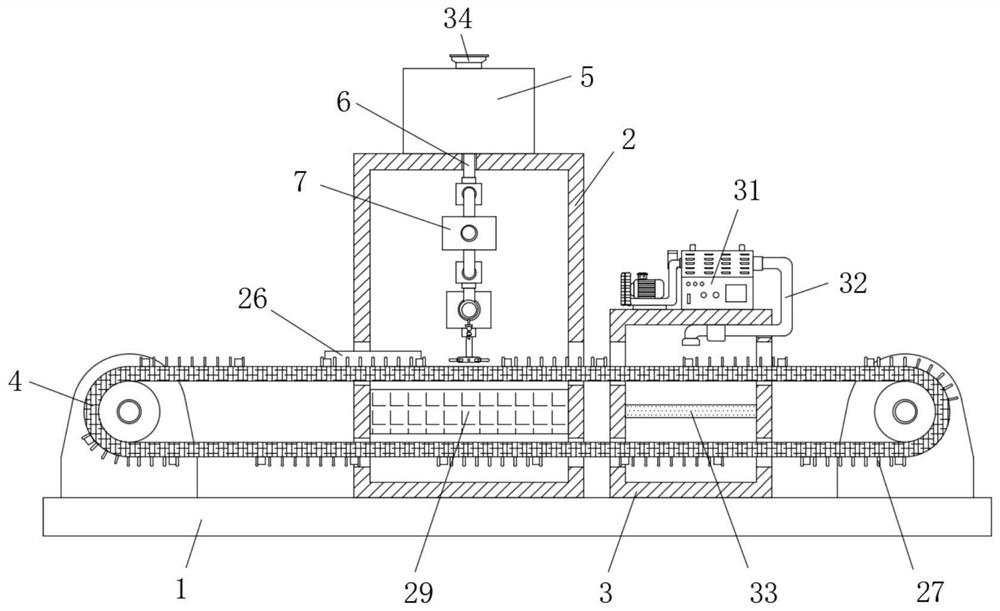

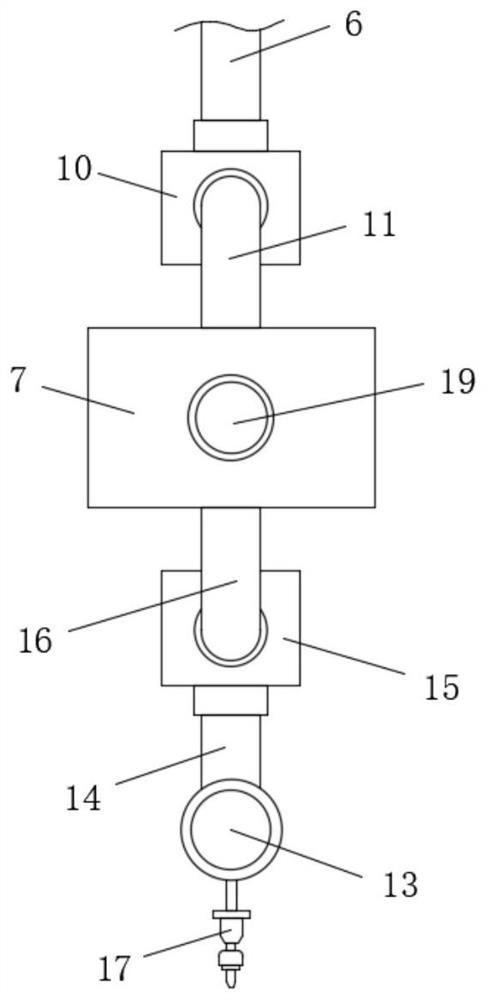

[0040] refer to Figure 1-11 , an intelligent uniform spraying device for flame retardant production, comprising a bottom plate 1, the top of the bottom plate 1 is fixedly connected with a spray box 2 and a drying box 3, and a drive connection is connected with a spray box 2 and a drying box respectively. 3, the conveyor belt 4, the top outer wall of the spray box 2 is fixedly connected with a storage box 5, the bottom of the storage box 5 is provided with a discharge pipe 6, and the bottom end of the discharge pipe 6 extends to the inside of the spray box 2 , a fixed block 12 is arranged on the inner walls of the opposite sides of the spray box 2, that is, two fixed blocks 12 are symmetrically fixedly connected, and the same group of spray assemblies is fixedly connected between the two fixed blocks 12, and the spray assembly is located at the conveying The top of the belt 4 is connected with the bottom end of the discharge pipe 6, two groups of transmission components are sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com