Method and device for cleaning micro-nano particles by time-controlled double-beam laser induced shock waves

A micro-nano particle, laser-induced technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, cleaning flexible objects, etc., can solve the problems of reducing the efficiency of shock wave cleaning and restricting applications, so as to avoid direct interaction, control convenience, The effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

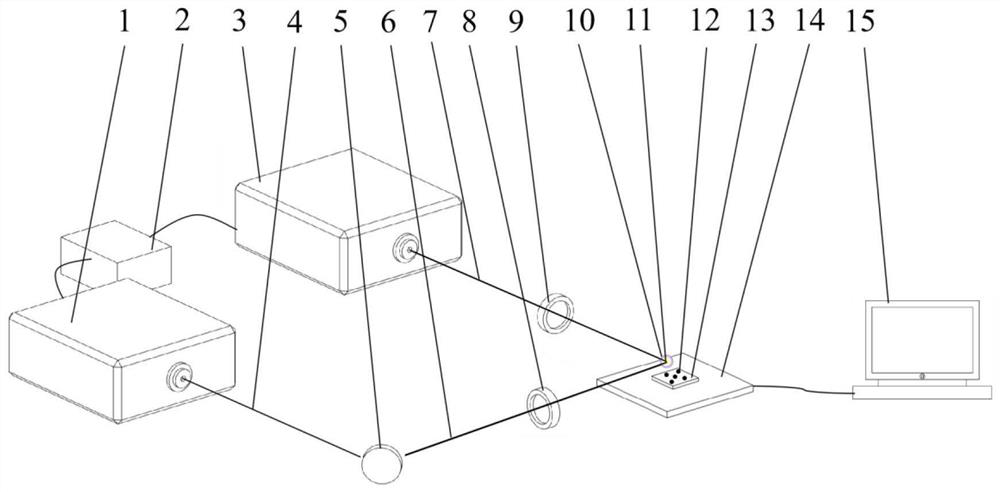

[0027] refer to figure 1 and figure 2 , a time-regulated double-beam laser-induced shock wave cleaning method for micro-nano particles, comprising the following steps:

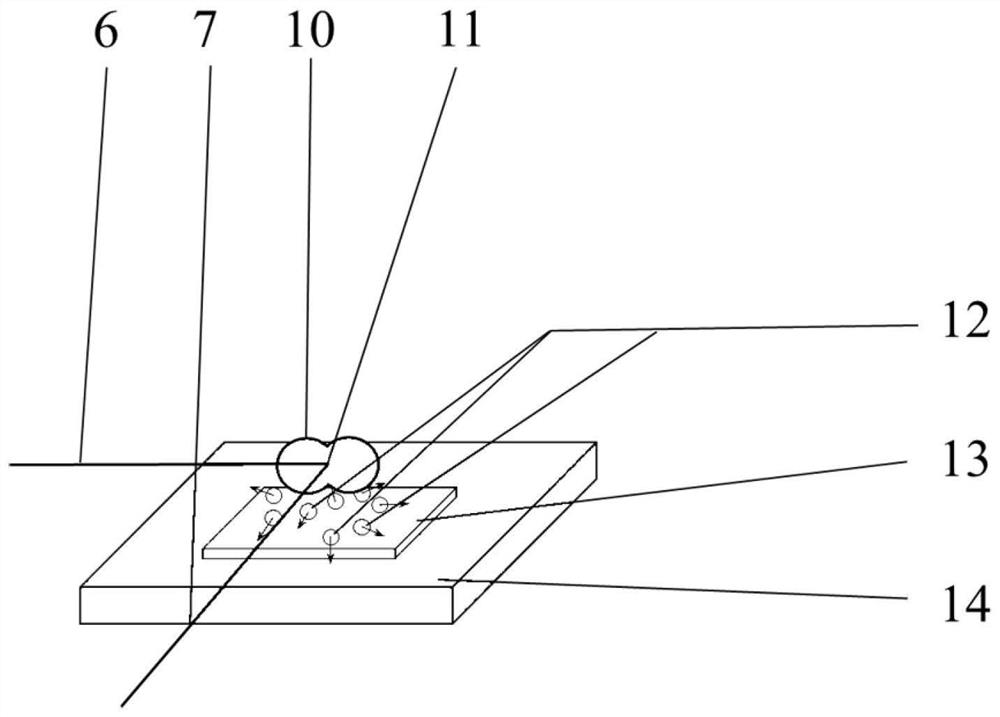

[0028] 1) Place the substrate 13 to be cleaned on the three-dimensional mobile platform 14, and move the three-dimensional mobile platform 14 so that the surface of the substrate 13 to be cleaned is located below the laser focus 11;

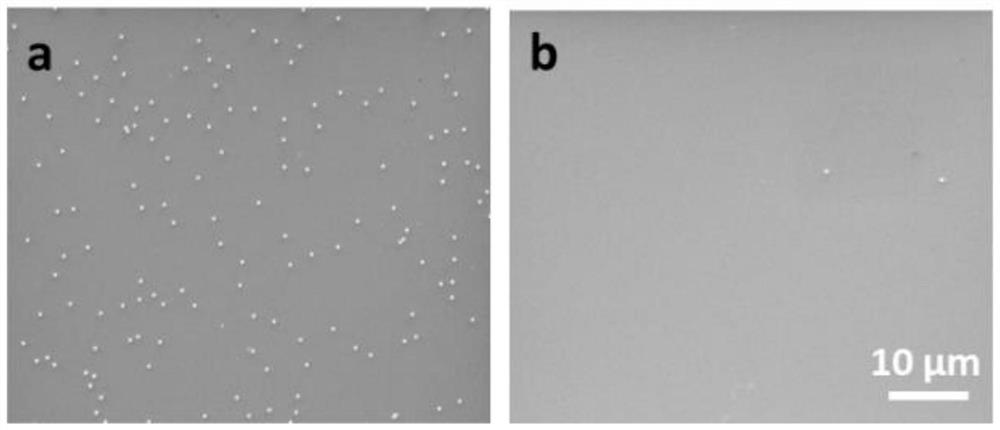

[0029] 2), using two focusing mirrors to focus the double-beam pulsed laser beams in the gas above the surface of the substrate 13 to be cleaned to induce gas breakdown, the double-beam pulsed laser beams are generated by two lasers, and the distance between the double-beam pulsed laser beams The delay time is regulated by the digital delay generator 2, and the time interval between the two beams is between 0-100 μs; a plasma shock wave is generated, and under the forc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com