Rotatable equipment for robot polishing and feeding

A technology of rotating equipment and robots, applied in grinding/polishing equipment, metal processing equipment, grinding machine parts, etc., can solve the problems of affecting the grinding effect, large footprint, small load, etc., to reduce the need for positioning accuracy , The effect of increasing rigidity and bearing capacity and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

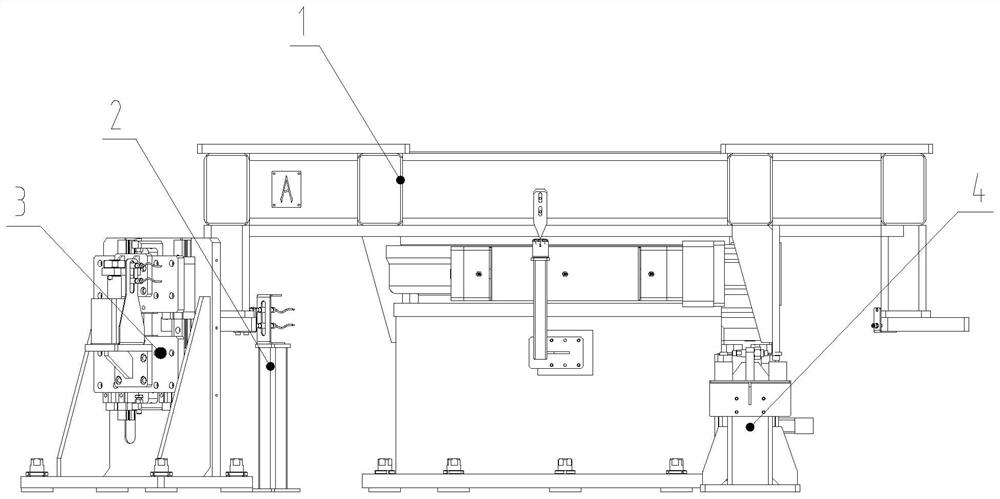

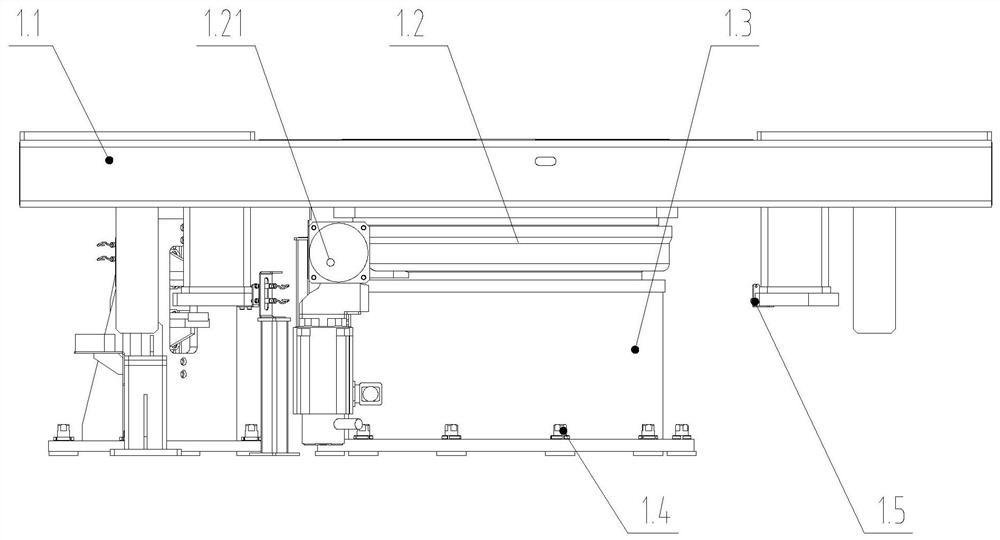

[0024] Such as Figure 1 to Figure 8 As shown, a rotatable device for grinding and feeding by a robot includes a rotating body 1 that cooperates with an external control system to support the entire device, and also includes a detection component 2 for detecting whether the rotating body 1 is in place. A clamping device 3 for fixing the rotating body 1 and a limiting assembly 4 for preventing the rotating body 1 from over-limit rotation.

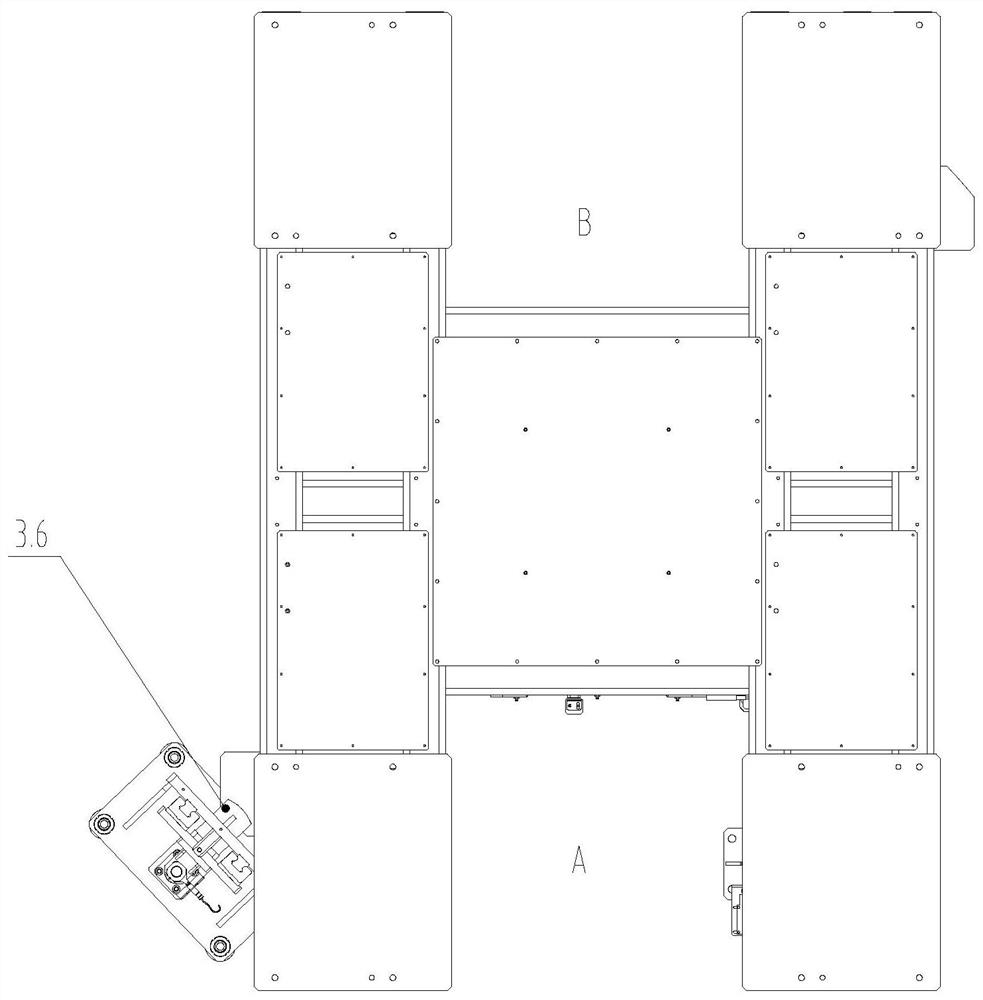

[0025] Such as figure 2 As shown in the figure, there are marked A and B in the figure. The workpiece is manually loaded to A, and the equipment drives A to rotate to work position B. At the same time, the finished parts at B are brought to A by the turntable, and the material is manually unloaded, repeating. this action.

[0026] Through the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com