Six-degree-of-freedom series robot tool and zero error rapid calibration method based on a genetic algorithm

A genetic algorithm and error calibration technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of no way to eliminate, influence on point calibration results, etc., to avoid unstable calibration results, fast and simple cost, robustness strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

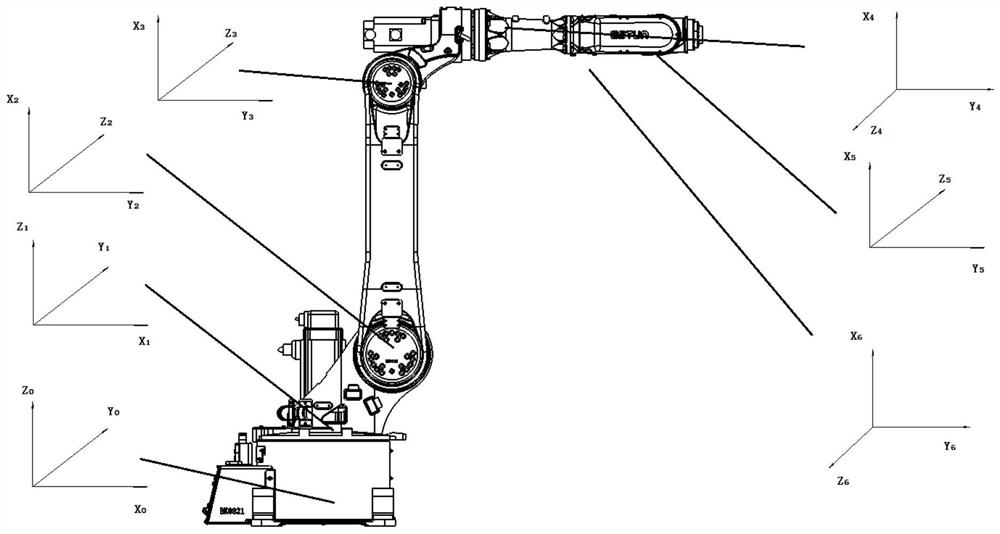

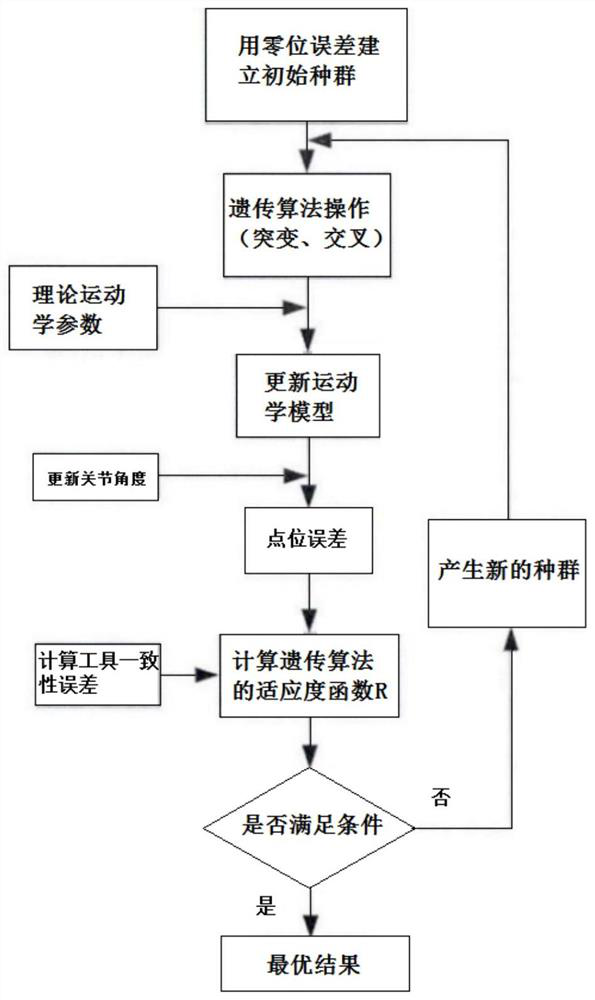

[0036] Specific implementation method: combined Figure 1 to Figure 4 , this embodiment is based on a genetic algorithm-based six-degree-of-freedom serial robot tool and a rapid calibration method for zero error, specifically in accordance with the following steps:

[0037] Step 1: Establish the actual model of the robot through the DH parameter modeling method of the robot;

[0038] Step 11: If figure 1 As shown, the D-H error model of the robot is established, and the two connected connecting rod axes are specified as i and i-1 respectively, and the common normal line of the connecting rod axes i and i-1 is set as the connecting rod length a i-1, the angle formed by the two connecting rods is set as the torsion angle α i-1 , and the distance between the two public normals is the connecting rod offset d i , a i-1 and a i The angle between them is θ i , called the joint angle. The D-H error model of the robot is composed of the above four parameters (the length of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com