Damper live-line disassembly and assembly robot capable of automatically getting on and off line

A technology of anti-vibration hammers and robots, which is applied to overhead lines/cable equipment, manipulators, manufacturing tools, etc. It can solve problems such as the difficulty of lifting robots on and off the line, and achieve the effects of solving operational limitations, avoiding shaking, and simplifying methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

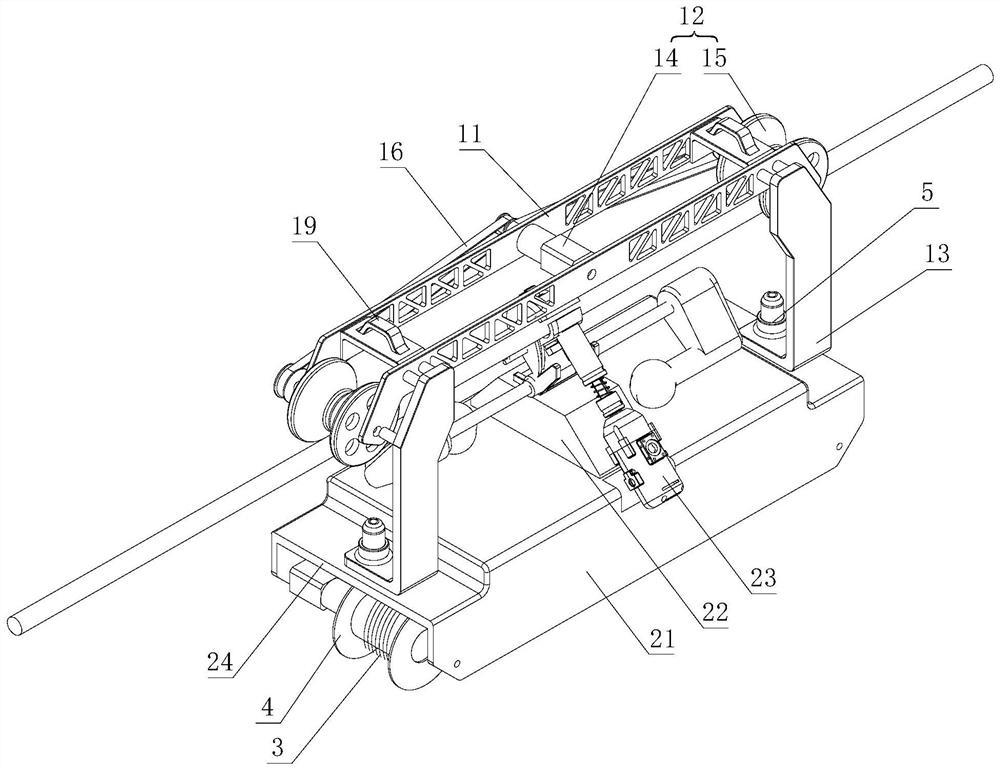

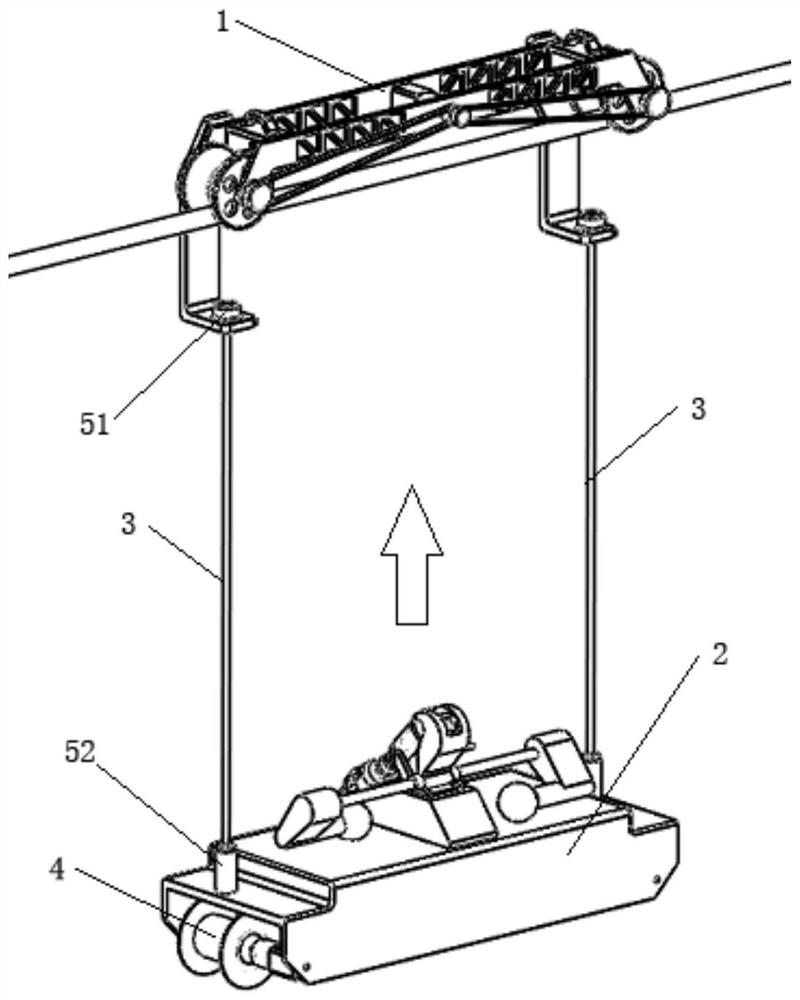

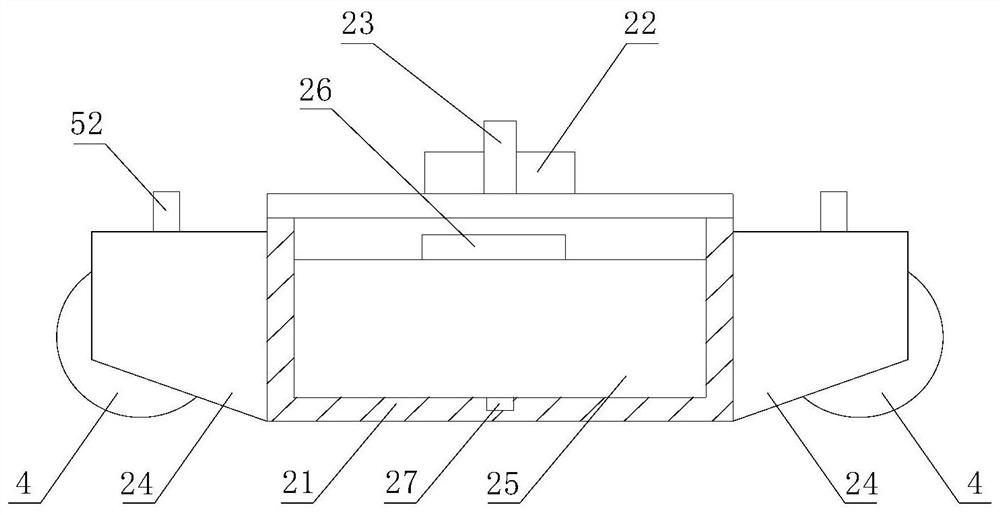

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a live disassembly robot for an anti-vibration hammer that can go on and off the assembly line autonomously includes a suspension assembly 1 suspended on a wire, and a main body 2 for live disassembly of the anti-vibration hammer. The suspension assembly 1 is provided with a The main body 2 is connected to the insulating rope 3, and the main body 2 is provided with a hoisting mechanism 4 that controls the winding and unwinding of the insulating rope 3. When the insulating rope 3 is wound, the main body 2 moves upward under the reaction force.

[0024] The whole anti-vibration hammer live disassembly robot is suspended on the wire through the suspension component 1. Since the host and the suspension component 1 are connected by the insulating rope 3, the main body 2 can be controlled only by controlling the winding and unwinding of the insulating rope 3. Relative to the rising and falling movement of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com