Autoclaved aerated concrete block manufacturing equipment and process

A concrete block, autoclaved gas filling technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problem of incompatibility between pressure resistance and heat preservation, to improve the pressure resistance and heat preservation, easy installation, convenient The effect of building construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

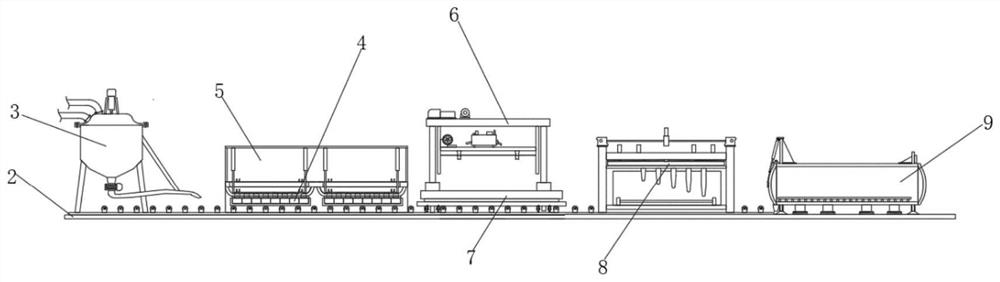

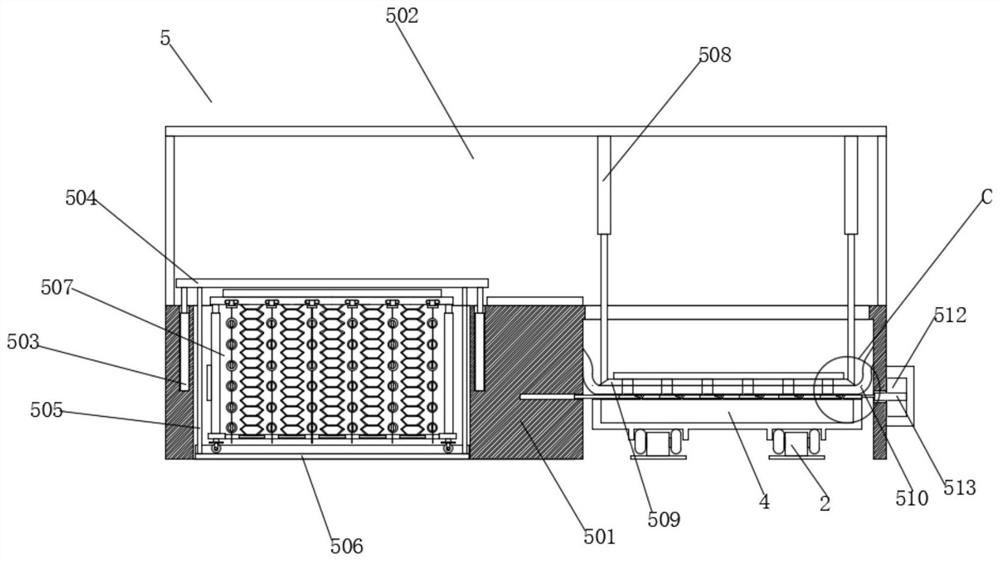

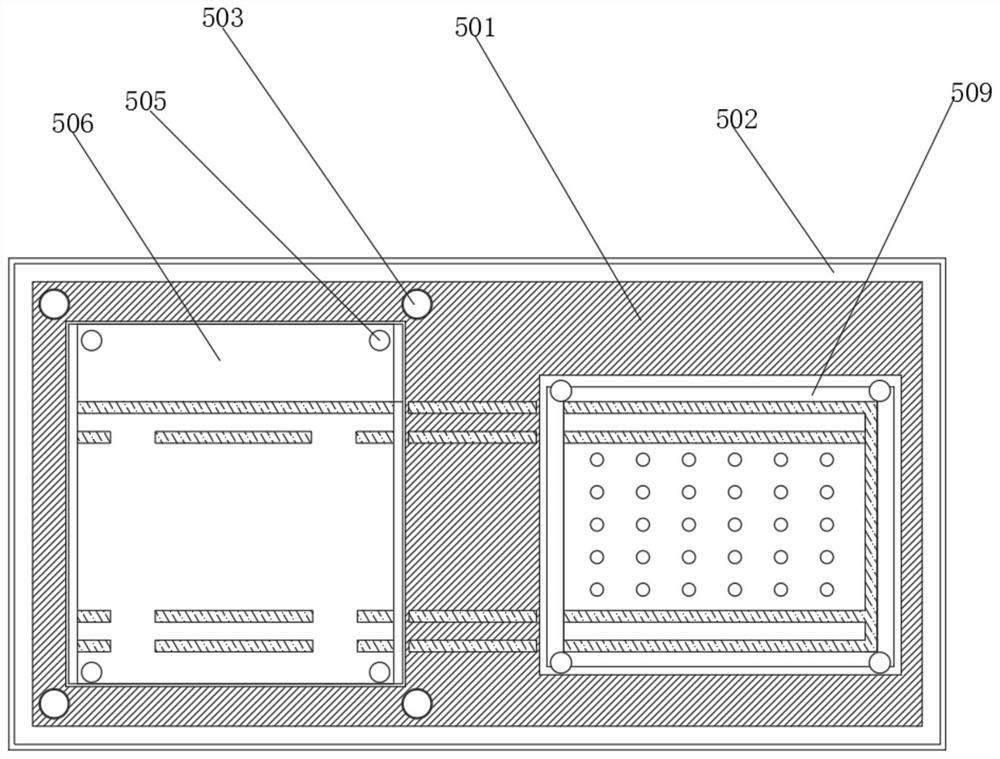

[0041] see Figure 1-3 , an autoclaved aerated concrete block production equipment, comprising a molding die 1 for making block pellets, a feeding track 2 and a mixing device 3 sequentially arranged on the feeding track 2, a first feeding trolley 4, a forming Device 5, clamping mechanism 6, second feeding trolley 7, cutting device 8 and autoclaving device 9, forming device 5 includes a device shell 501, and the inside of the device shell 501 is sequentially provided with a lifting cavity and a first feeding chamber from front to back. In the maintenance chamber where the trolley 4 passes, the top of the device housing 501 is fixedly connected with an isolation cover 502, and the top of the device housing 501 is respectively provided with four lifting hydraulic cylinders 503 near the four corners of the lifting chamber, and the output ends of the lifting hydraulic cylinders 503 are fixedly connected with supports Top plate 504, four corners of the bottom surface of supporting t...

Embodiment 2

[0044] see Figure 4-5 The molding die 1 includes a bottom shell 101 and a mold cover 102 installed on the bottom shell 101, and the top surface of the bottom shell 101 is provided with a hemispherical mold groove, and the bottom surface of the mold cover 102 is fixedly connected with a The hemispherical bulge, and the center of the hemispherical bulge is provided with a transverse through groove, and the top of the bottom shell 101 is provided with a wire groove communicating with the mold groove.

[0045] The difference from Example 1 is that the protrusions provided on the mold cover 102 in the molding die 1 can ensure that a hemispherical hollow shell can be formed after the mold is formed, and the hemispherical protrusions on the mold cover 102 The horizontal through groove provided can make the formed hemispherical block ball have a horizontal plate inside, which is convenient for the insertion of the plastic plate on the subsequent binding rope, and ensures the firm and...

Embodiment 3

[0047] see Figure 6-8 The movable trolley 507 includes a bottom frame 5071 and a discharge hydraulic cylinder 5072 arranged on the top of the bottom frame 5071. The top of the discharge hydraulic cylinder 5072 is fixedly connected with a discharge top plate 5073, and the surface of the bottom frame 5071 is evenly provided with several The bottom surface of the discharge top plate 5073 is slidably connected with a clamping strip 5074 through the chute, and the bottom of the clamping strip 5074 is fixedly connected with a number of PP material binding ropes, and the front of the clamping strip 5074 The shape is earth-shaped, the bottom horizontal plate of the clamping strip 5074 is located outside the discharge top plate 5073 and the bottom surface of the clamping strip 5074 is fixedly connected with the traction rope on the small ball of the block, and the bottom surface of the discharge top plate 5073 is fixedly connected with a wrinkled shape. rubber cloth 5075, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com