Manufacturing method of ring rib buckling connection part

A manufacturing method and snap-fit connection technology, which is applied in the direction of manufacturing tools, mold auxiliary parts, ceramic molding machines, etc., can solve the difficulties in ensuring the appearance quality of component concrete, the difficulty in ensuring the quality of connection between ring bars and components, and the positioning of reserved ring bars Inaccurate and other problems, to achieve the effect of not easy to deform, good processability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

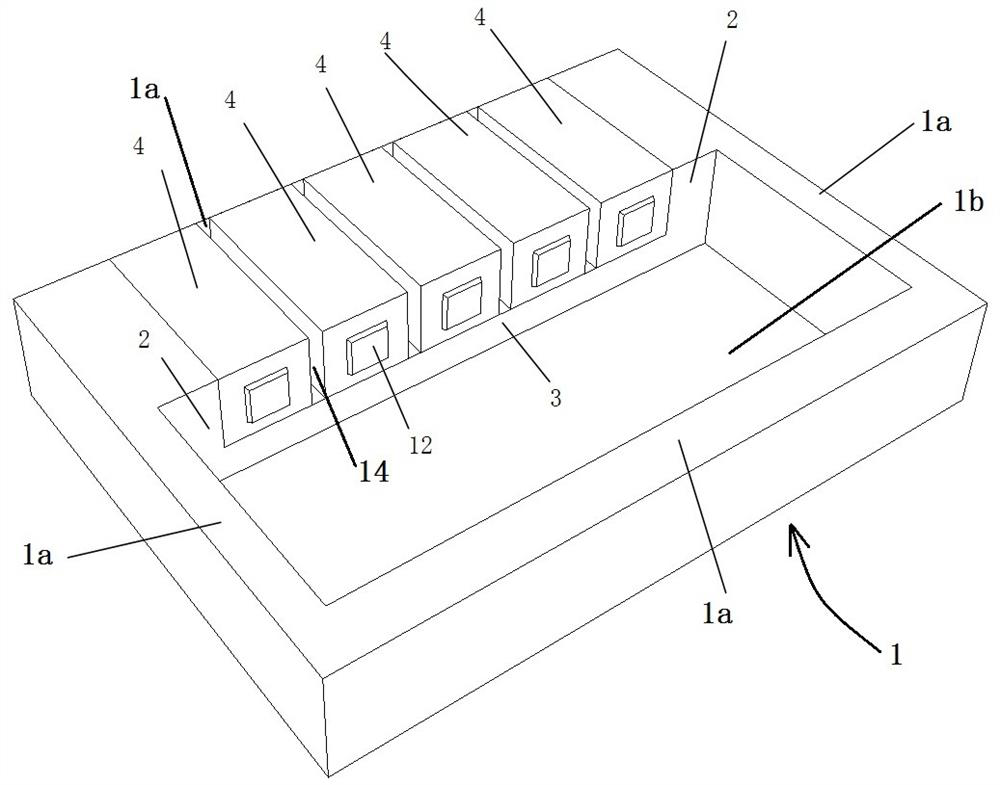

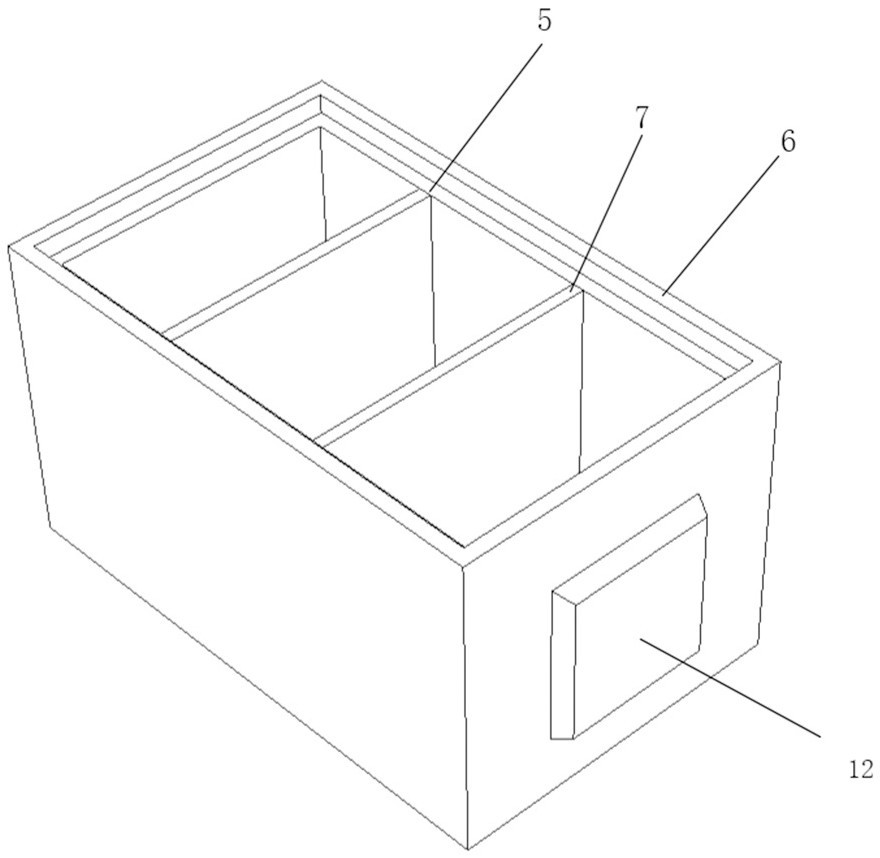

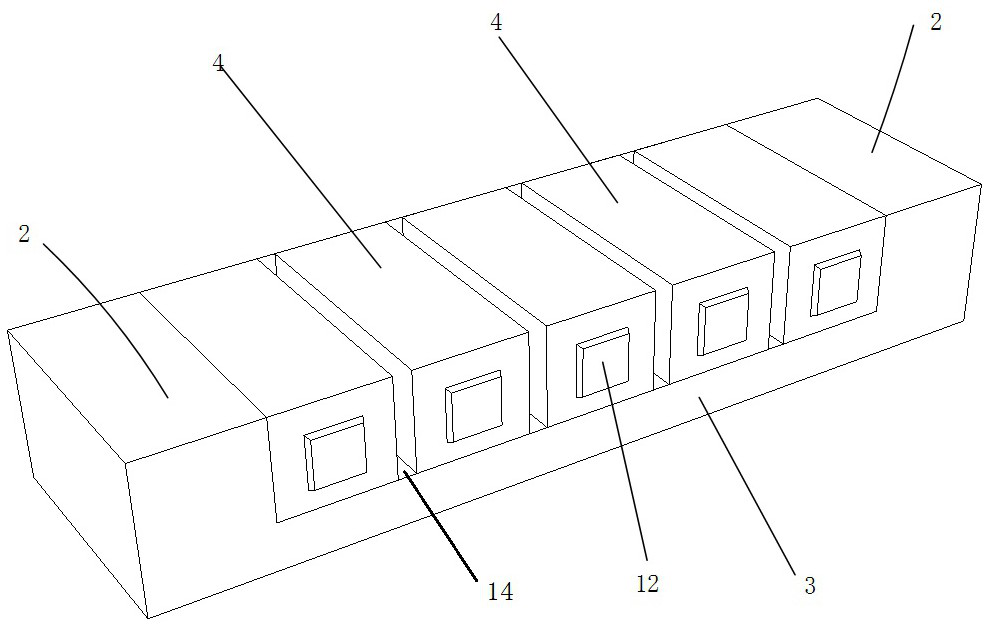

[0026] Example: such as figure 1 , 2 , 3, 4, and 5, the present embodiment specifically relates to a manufacturing method of a snap-fit connection member with ring bars, the manufacturing method comprising the following steps:

[0027] (1) if figure 1 , 3 As shown, according to the geometric size and configuration of the prefabricated component 11 to be processed, the mold main body 1 is processed and manufactured. The mold main body 1 is mainly composed of four side molds 1a to form a rectangular frame, and a bottom mold 1b is arranged at the bottom of the rectangular frame, so that The mold main body 1 has a cubic bin body; the cubic bin body is divided into a front half bin body and a rear half bin body, and a bar-shaped base 3 is arranged horizontally in the front half bin body, and one or more groups of mold main bodies 1 are divided into corresponding In the area of ring ribs and areas without ring ribs, and in the part with ring ribs, several cavity blocks 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com