Paperboard packaging box manufacturing and forming binding machine and method

A packing box and cardboard technology, which is applied in the field of cardboard box making and forming nailing machines, can solve the problems of wrinkling and deformation of binding parts, increasing labor intensity of workers, difficult linear alignment of carton boards, etc., to improve friction, improve operating efficiency, Avoid the effect of tilt offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

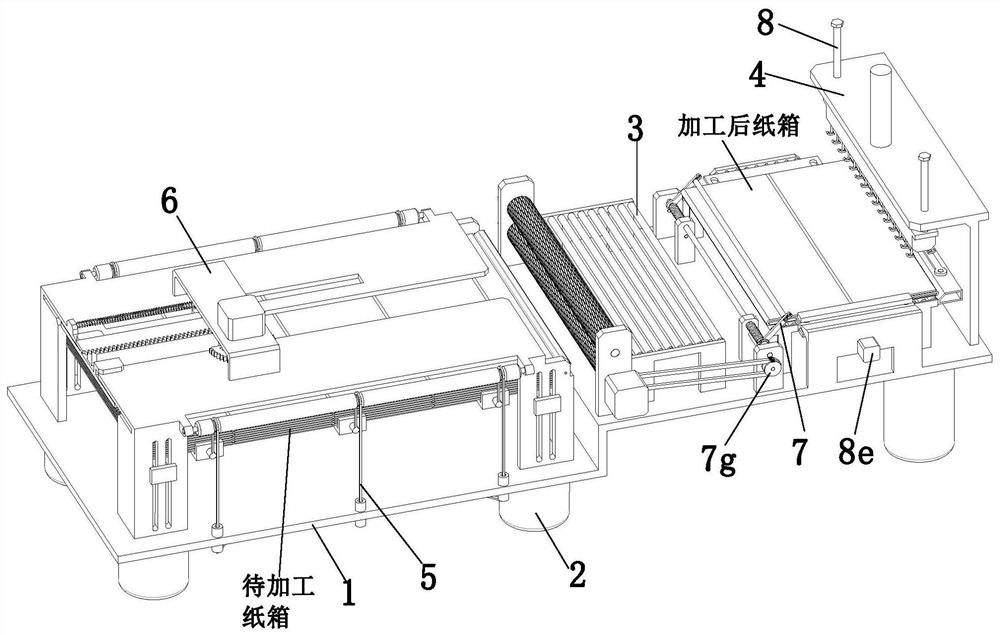

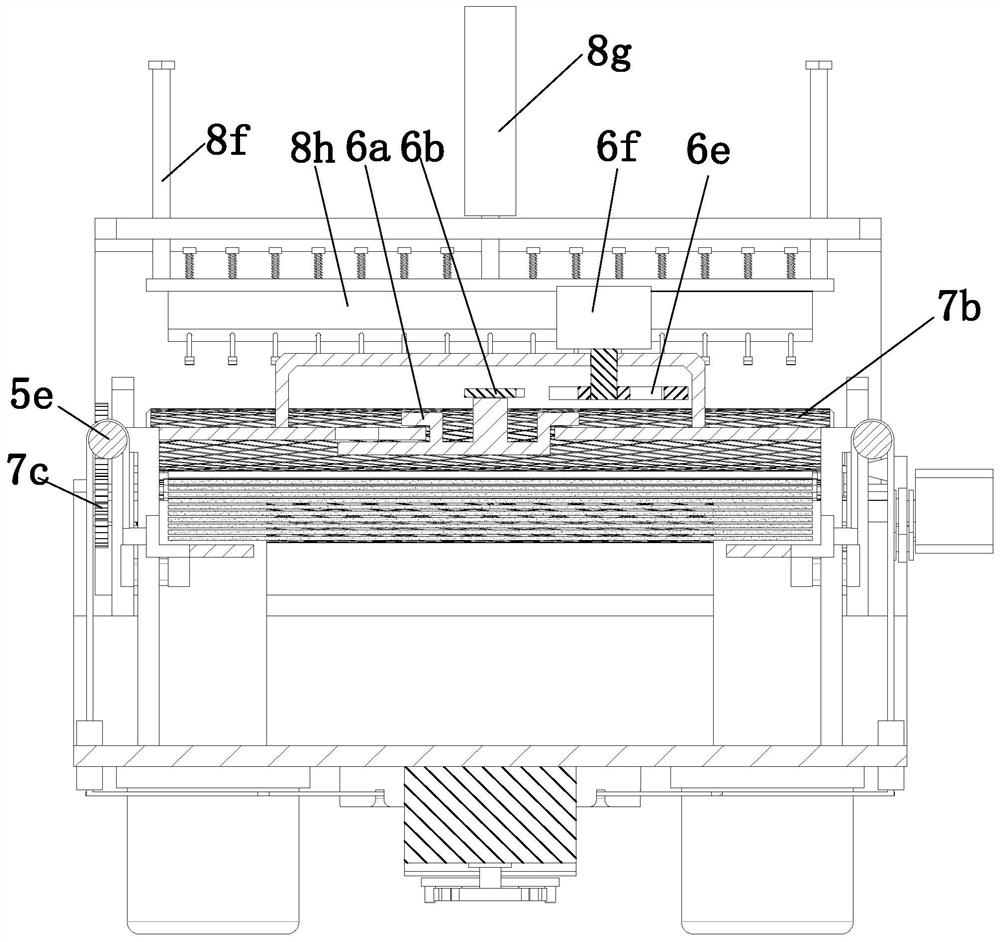

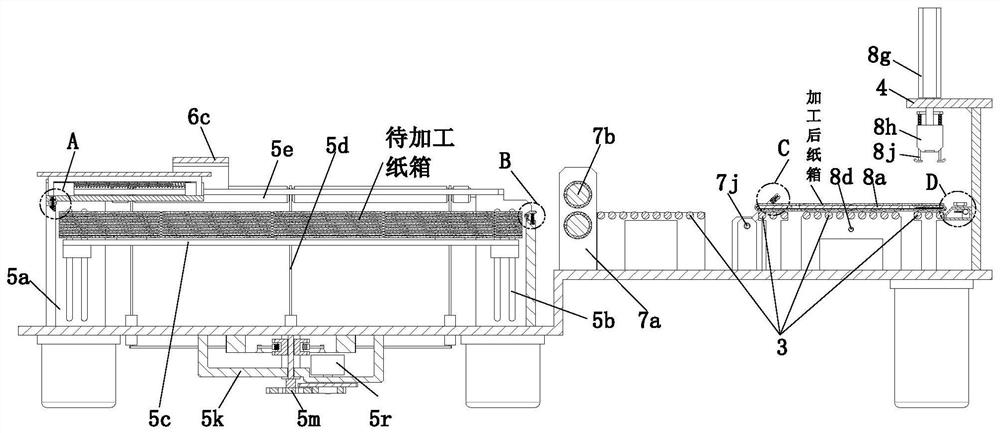

[0039] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0040] A nailing machine for making cardboard packaging boxes, including a mounting frame 1, a supporting foot 2, a supporting shaft 3, an L-shaped plate 4, a palletizing mechanism 5, a conveying mechanism 6, a folding mechanism 7 and a binding mechanism 8, the installation Support feet 2 are evenly installed on the lower end of the frame 1, a palletizing mechanism 5 is installed on one end of the mounting frame 1, a conveying mechanism 6 is installed on the palletizing mechanism 5, and an L-shaped plate 4 is installed on the other end of the mounting frame 1, and an L-shaped plate 4 A binding mechanism 8 is installed on it, and a folding mechanism 7 is installed on the mounting frame 1 between the L-shaped plate 4 and the conveying mechanism 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com