Cleaning method for ink-jet printer accessory nozzle

The technology of an inkjet printer and a cleaning method, which is applied in printing and other directions, can solve the problems affecting the printing accuracy and service life of the nozzle of the inkjet printer, clean the ink inside the nozzle of the inkjet printer, and damage the piezoelectric ceramics, etc., so as to improve the printing accuracy and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

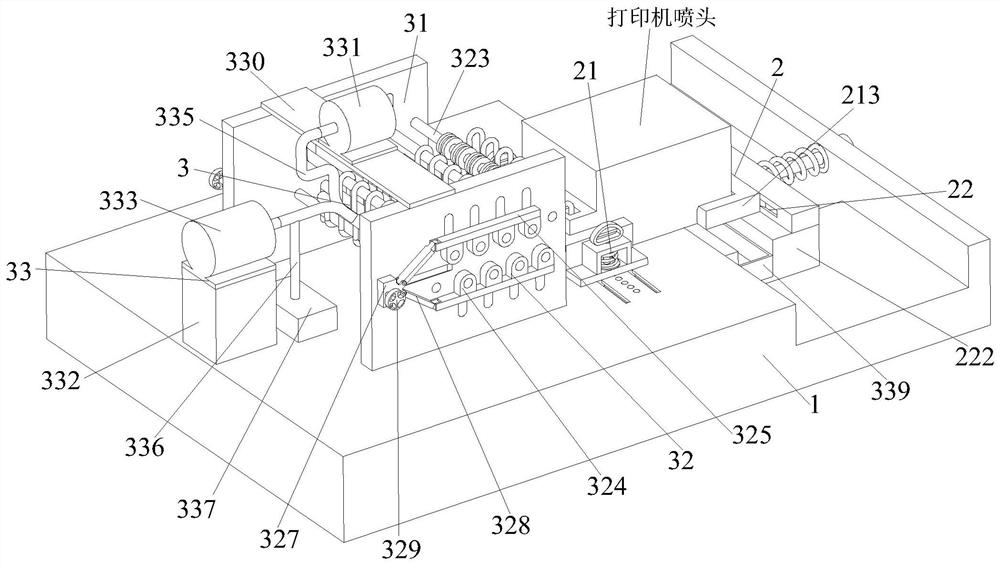

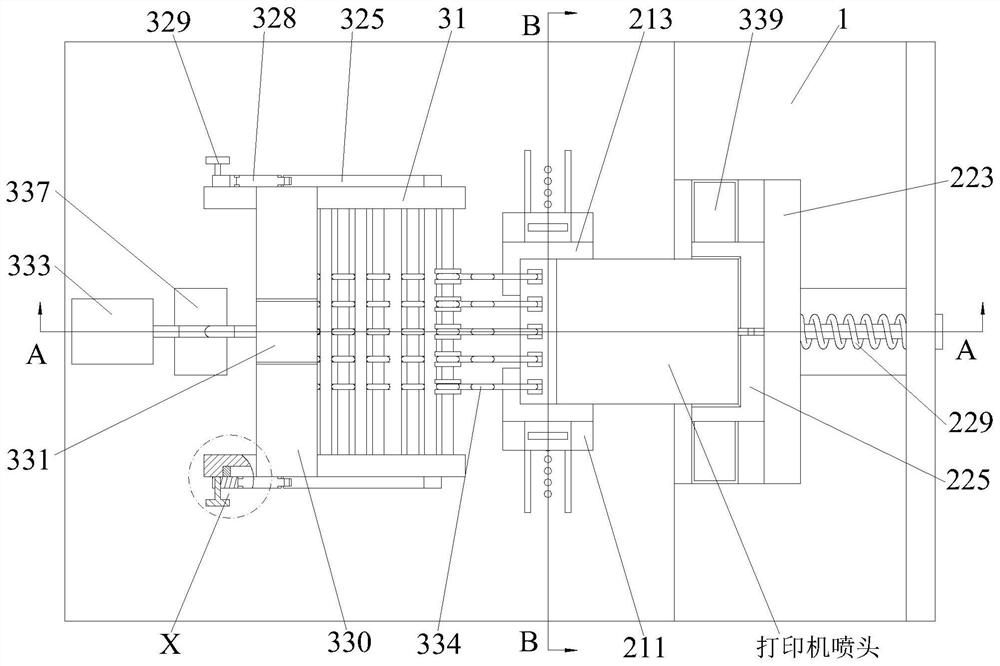

[0043] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 11 , to further elaborate the present invention.

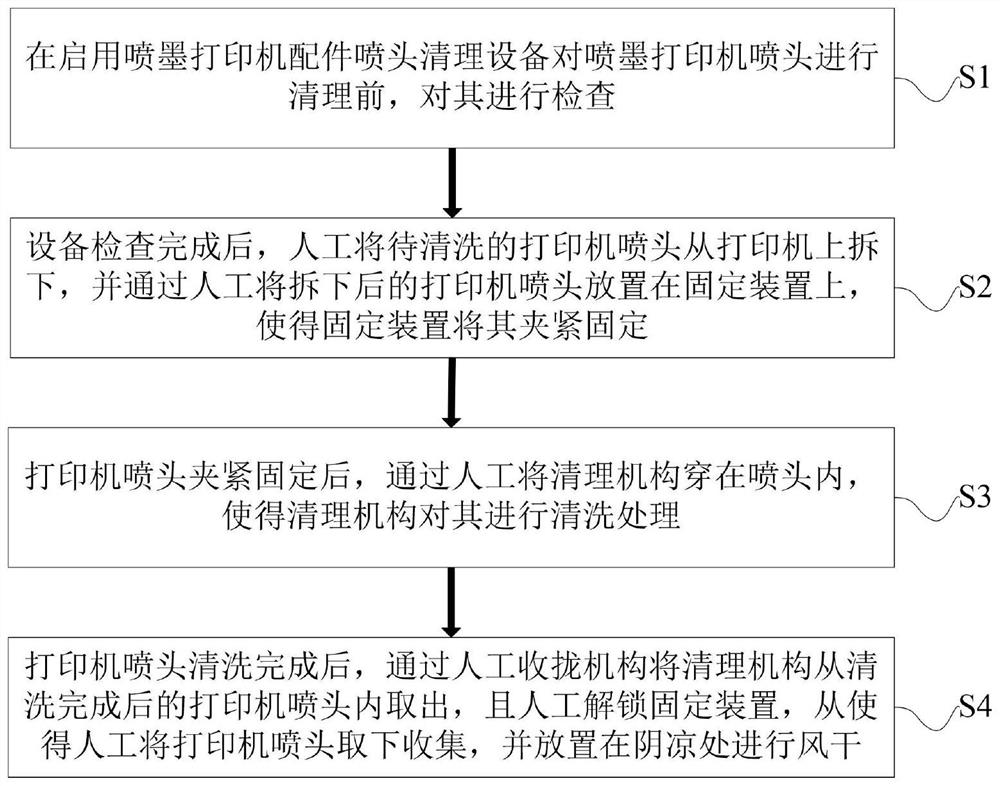

[0044] A method for cleaning nozzles of inkjet printer accessories, which uses a nozzle cleaning device for inkjet printer accessories. When the nozzle cleaning equipment cleans the inkjet printer nozzle, the specific method is as follows:

[0045] S1. Equipment inspection: check the nozzles of inkjet printers before using the nozzle cleaning equipment of inkjet printer accessories;

[0046] S2. Material loading process: After the equipment inspection is completed, the printer nozzle to be cleaned is manually removed from the printer, and the removed printer nozzle is manually placed on the workbench 1, and the adjustment rod 215 is pulled out manually, The workbench 1 is separated from the sliding plate 211, so that the position of the corner pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap