Conveyor belt push plate unloading device

A technology of unloading device and conveyor belt, which is applied in transportation and packaging, arrangement of loading and unloading vehicles, vehicles with endless chain/ring belt, etc. The effect of ideal sealing effect, low maintenance cost and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

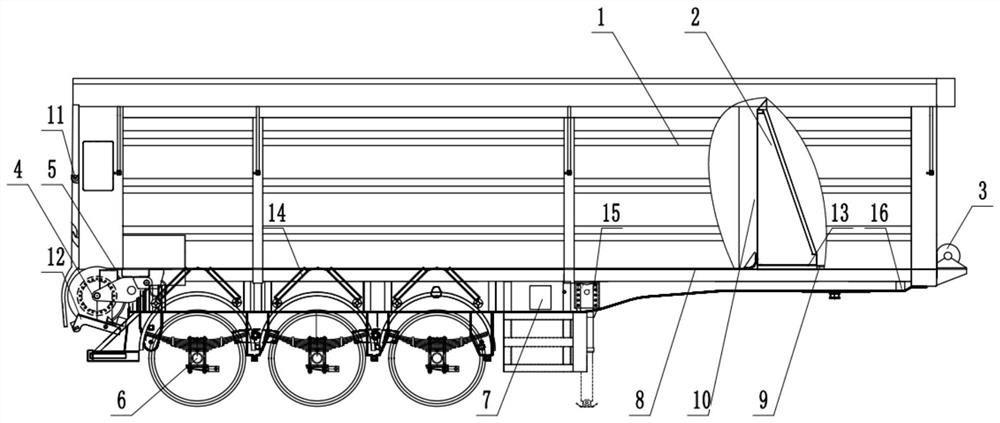

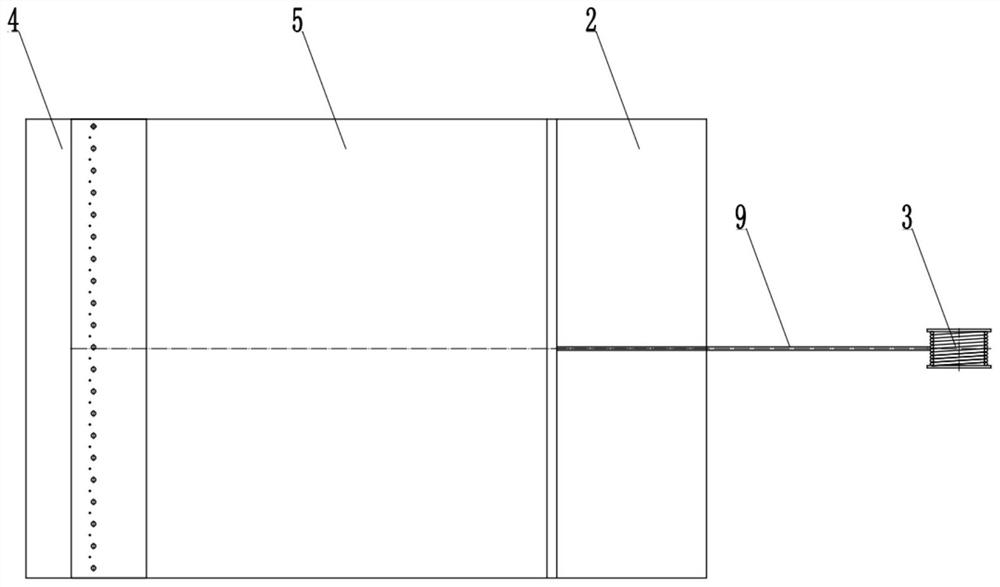

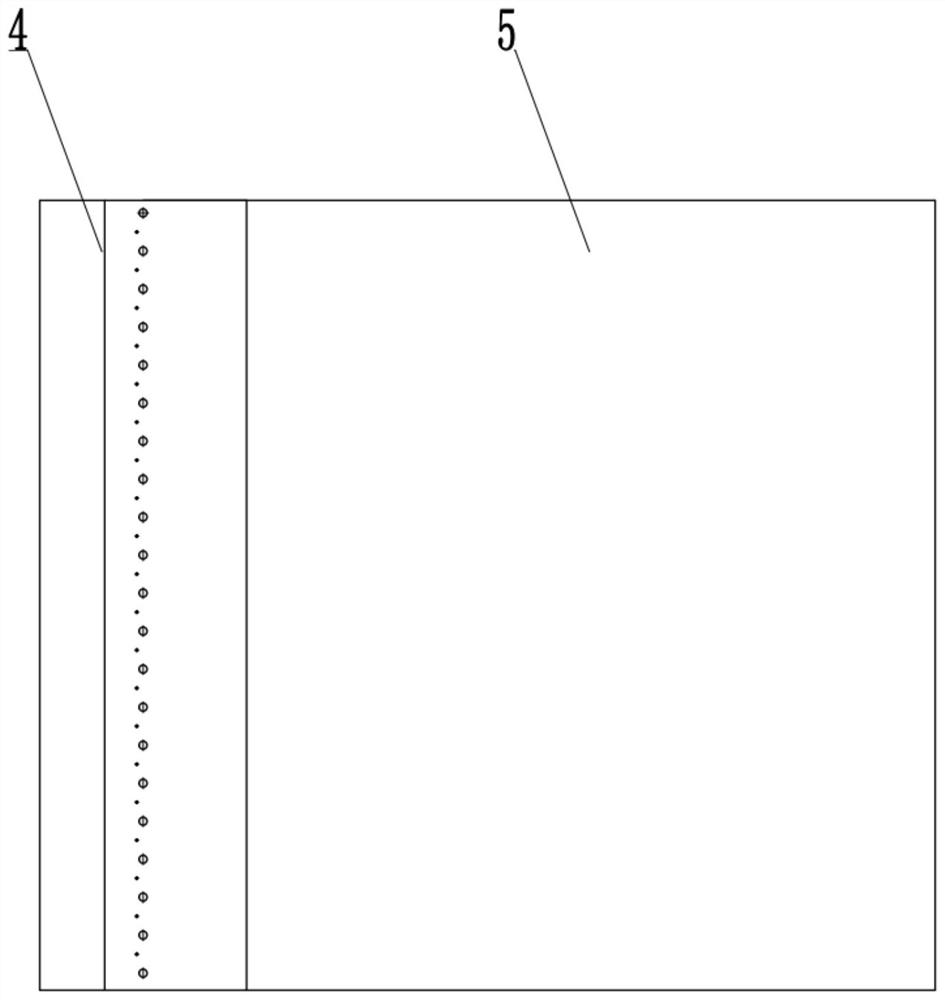

[0045] Such as figure 1 As shown, it is a schematic structural view of the conveyor belt push plate unloading device in Embodiment 1 of the present invention; as figure 2 As shown, it is a schematic view of the structure of the conveyor belt push plate unloading device in Embodiment 1 of the present invention; as image 3 As shown, it is a schematic diagram of the connection structure between the unloading roller and the unloading belt in the active recovery system in the conveyor belt push plate unloading device in Example 1 of the present invention; Figure 4 As shown, it is a schematic diagram of the connection structure between the unloading belt and the front plate in the active recovery system in the conveyor belt push plate unloading device in Embodiment 1 of the present invention; Figure 5 As shown, it is a schematic diagram of the connection structure between the front plate and the hydraulic winch in the active recovery system in the conveyor belt push plate unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com