Transport vehicle for cement poles in vertical state

A vertical state, cement rod technology, applied in the direction of transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of restrictions, large turning radius, and increase the difficulty of cement rods, so as to reduce the impact, reduce friction, and benefit the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

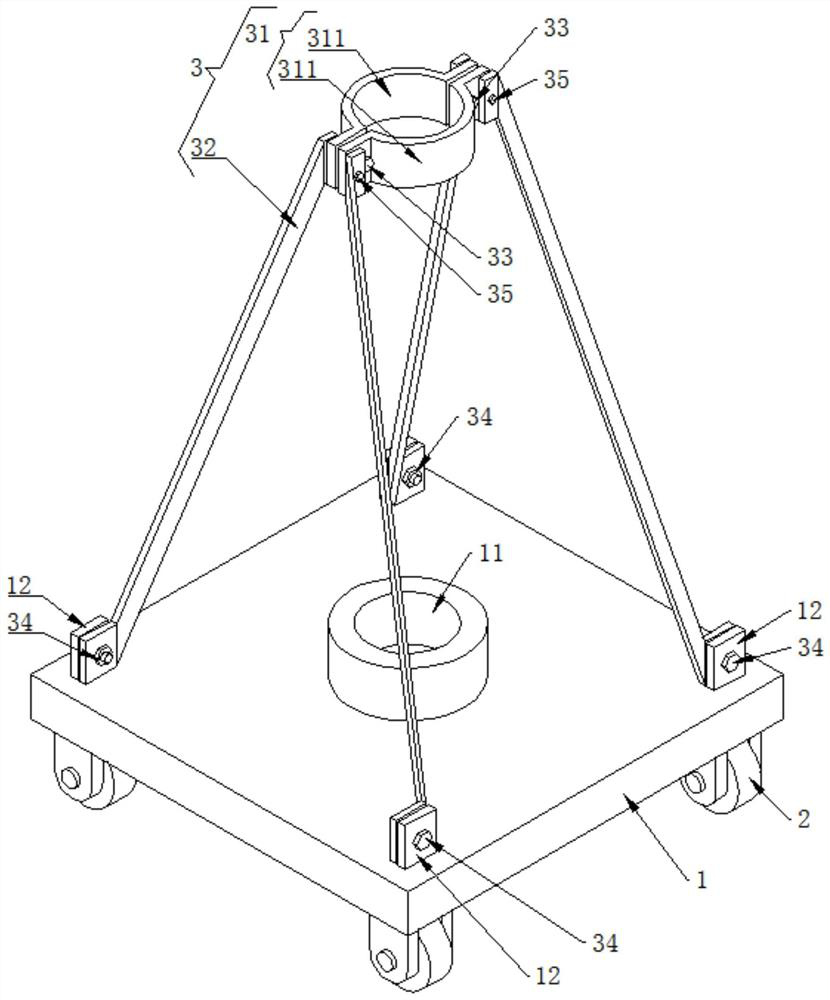

[0044] Such as figure 2 As shown, a cement rod transport vehicle in a vertical state includes a base 1 , moving wheels 2 , and a supporting mechanism 3 .

[0045] A moving wheel 2 is installed on the lower end surface of the base 1 .

[0046] The upper end surface of the base 1 is provided with a mounting groove 11, and the mounting groove 11 is used for inserting a cement rod in a vertical state.

[0047] A support mechanism 3 is provided above the base 1, and the support mechanism 3 is used to support the middle and upper part of the cement rod in a vertical state. The supporting mechanism 3 includes a hoop 31 and a supporting rod 32 . The hoop 31 includes at least two arc-shaped plates 311 for assembling into a ring structure. In this embodiment, the hoop 31 includes two arc-shaped plates 311, and the first fastener 33 adopts bolts. The shaped plates 311 are fastened together by bolts. There are at least two supporting rods 32. In this embodiment, there are four suppor...

Embodiment 2

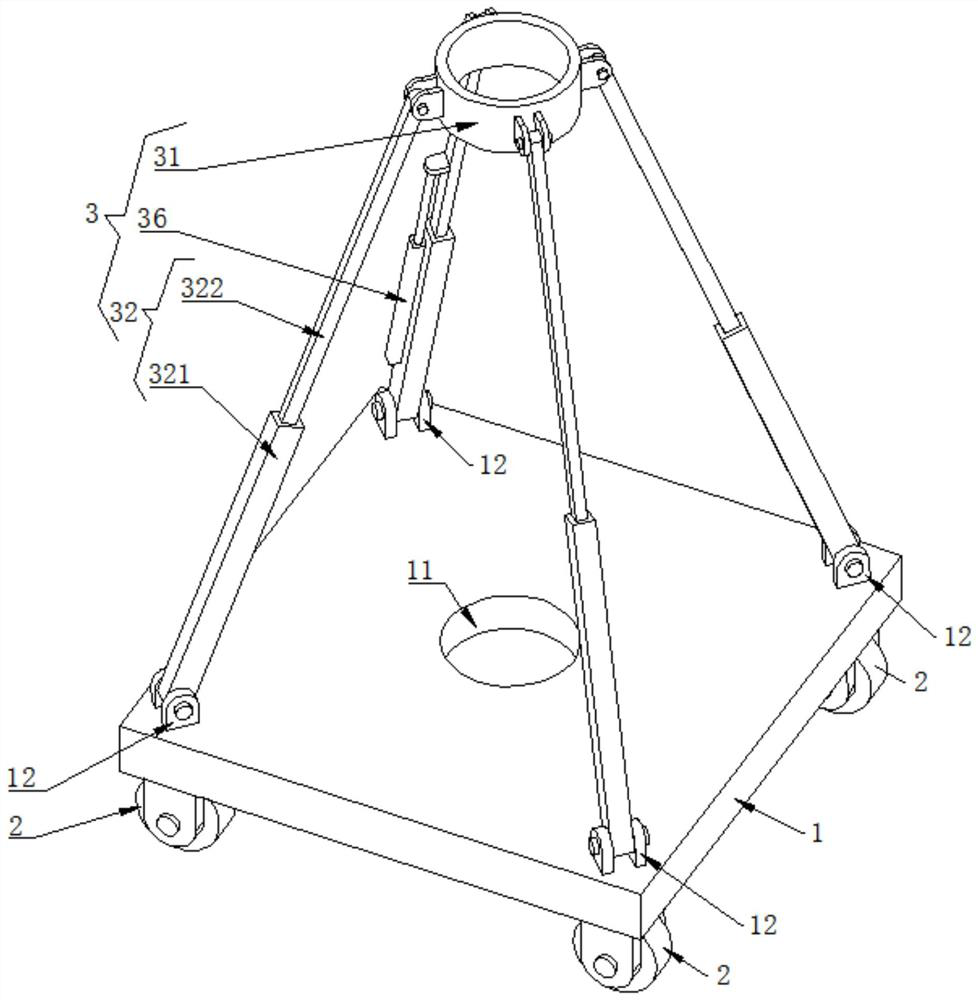

[0058] Such as image 3 As shown, a cement rod transport vehicle in a vertical state includes a base 1 , moving wheels 2 , and a supporting mechanism 3 .

[0059] A moving wheel 2 is installed on the lower end surface of the base 1 .

[0060] The upper end surface of the base 1 is provided with a mounting groove 11, and the mounting groove 11 is used for inserting a cement rod in a vertical state.

[0061] A support mechanism 3 is provided above the base 1, and the support mechanism 3 is used to support the middle and upper part of the cement rod in a vertical state. The supporting mechanism 3 includes a hoop 31 , a supporting rod 32 , and a supporting telescopic rod 36 . The hoop 31 is an annular structure. There are multiple supporting rods 32. In this embodiment, there are four supporting rods 32. These four supporting rods 32 are radially distributed with the installation groove 11 as the center of the circle. Each supporting rod 32 includes a supporting cover 321 and a...

Embodiment 3

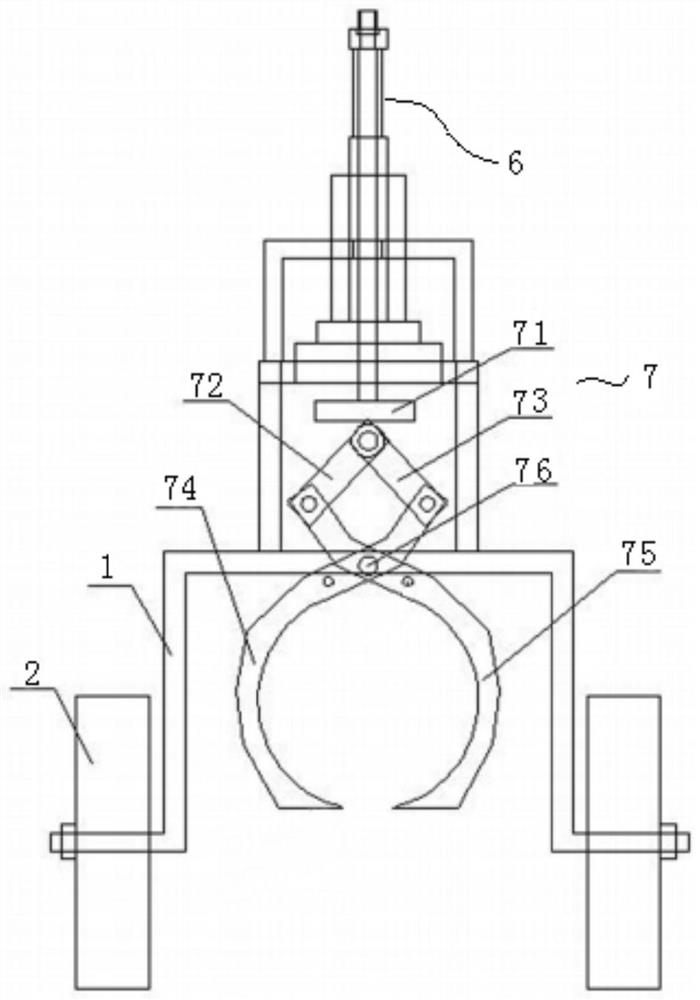

[0073] Present embodiment 3 makes further improvement on the basis of embodiment 1 or embodiment 2:

[0074] Such as Figure 4 with Figure 5 As shown, the upper end surface of the base 1 is provided with a feed hole 13, and the installation groove 11 communicates with the outside of the side wall of the base 1 through the feed hole 13, and the feed hole 13 is provided with an obliquely arranged guide plate 131 at an end close to the installation groove 11 , the lower end of the guide plate 131 is set away from the installation groove 11 , and the guide plate 131 is welded and fixed to the hole wall of the feed hole 13 .

[0075] A clamping mechanism 4 is provided on the upper surface of the base 1 , and the clamping mechanism 4 includes a fixed arc-shaped plate 41 , a movable arc-shaped plate 42 , and a driving assembly 43 .

[0076] The fixed arc-shaped plate 41 is arranged at the end of the installation groove 11 away from the feeding hole 13 , and the fixed arc-shaped pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com