Automatic hub collecting equipment

A technology of automatic material collection and hub, applied in transportation and packaging, conveyor objects, loading/unloading, etc., can solve the problems of consuming workers' time and physical strength, consuming workers' time, and hub weight, saving working time and reducing labor. Strength, the effect of avoiding handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0046] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

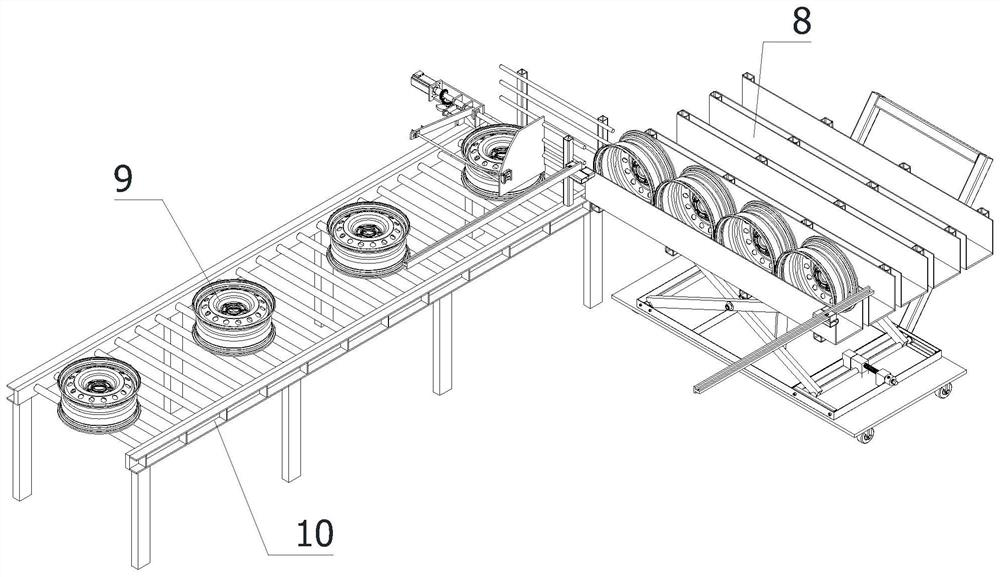

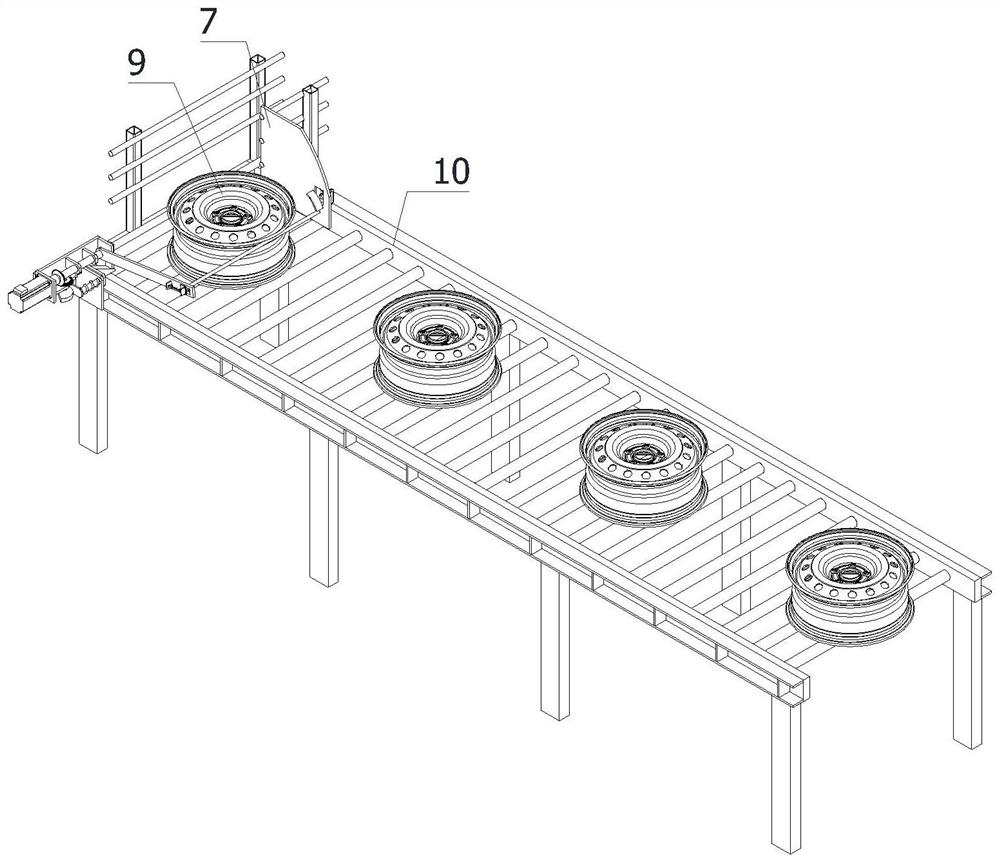

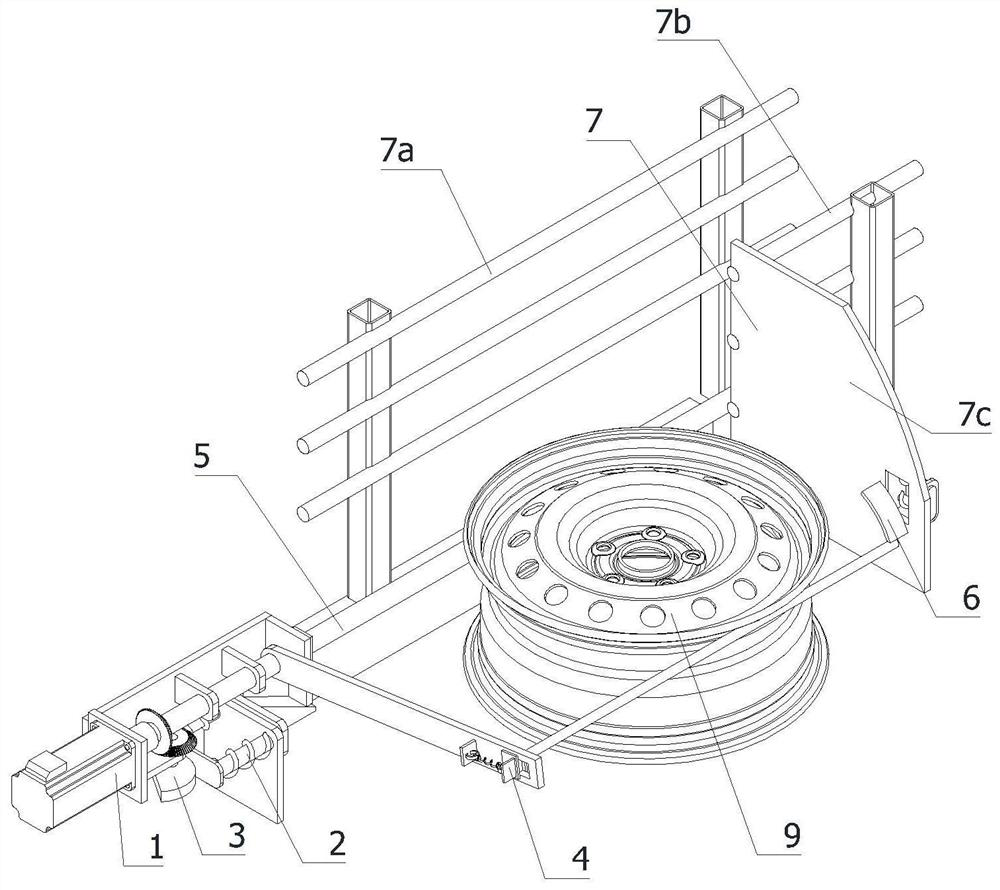

[0047] refer to Figure 1 to Figure 12 The shown automatic hub material receiving equipment includes a rotating mechanism 1, a push-up mechanism 2, a transmission mechanism 3, an elastic extruding arm 4, a rotating frame 5, a one-way expanding mechanism 6, a supporting guide frame 7, and a hub collecting vehicle 8 and the conveying line 10, the conveying line 10 is fixedly installed on the ground, several hubs 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com