Novel falling type empty frame conveying device

A conveying device, drop-type technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high failure rate, complex structure, difficult synchronous drive control of multiple sets of equipment, etc., to reduce the overall failure rate, High synchronization performance and reduced control device effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

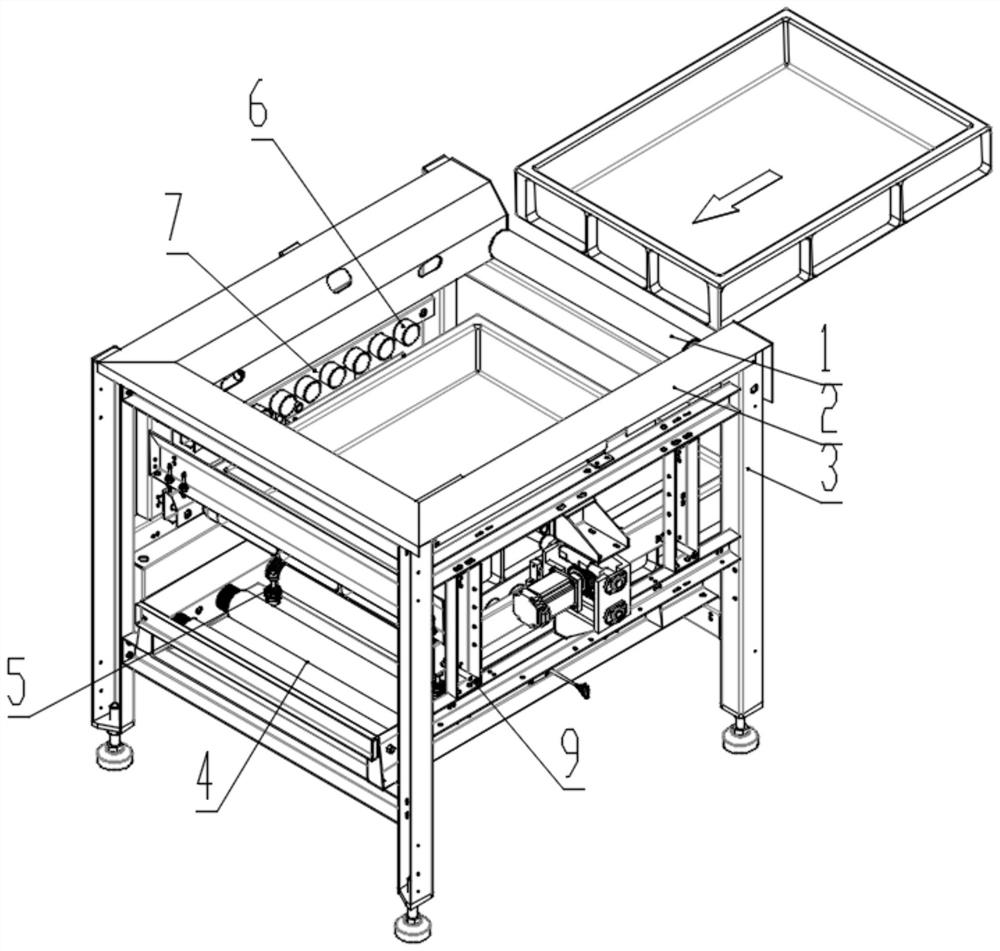

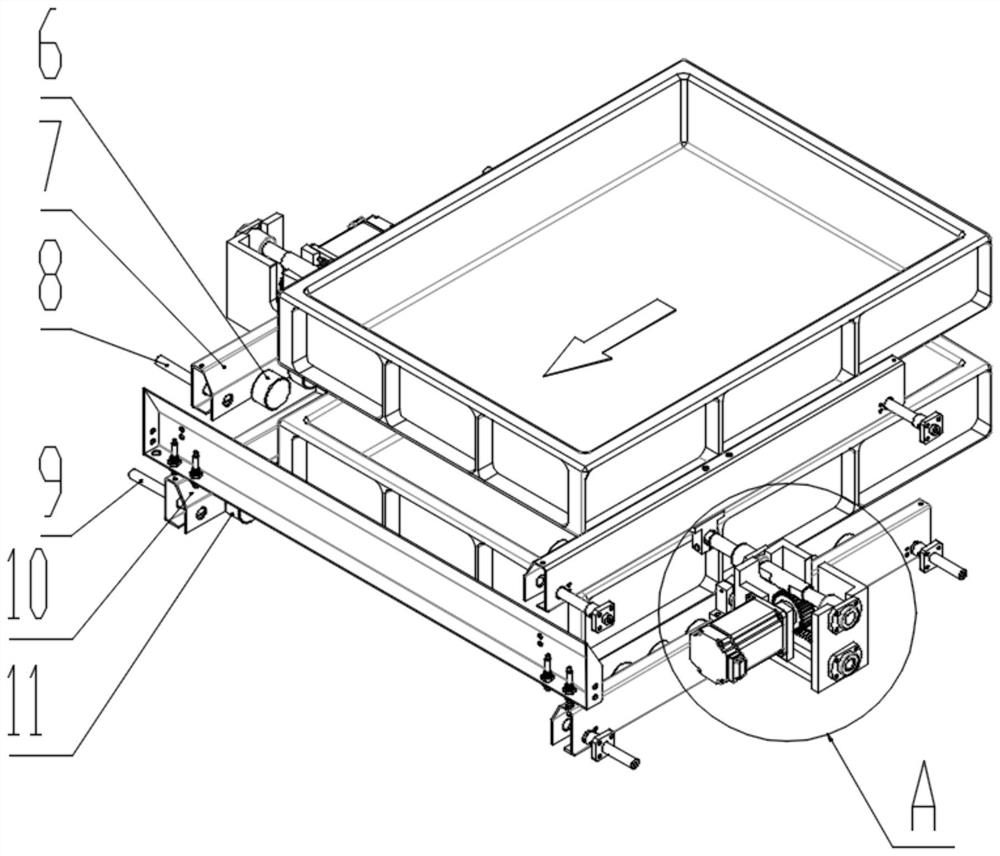

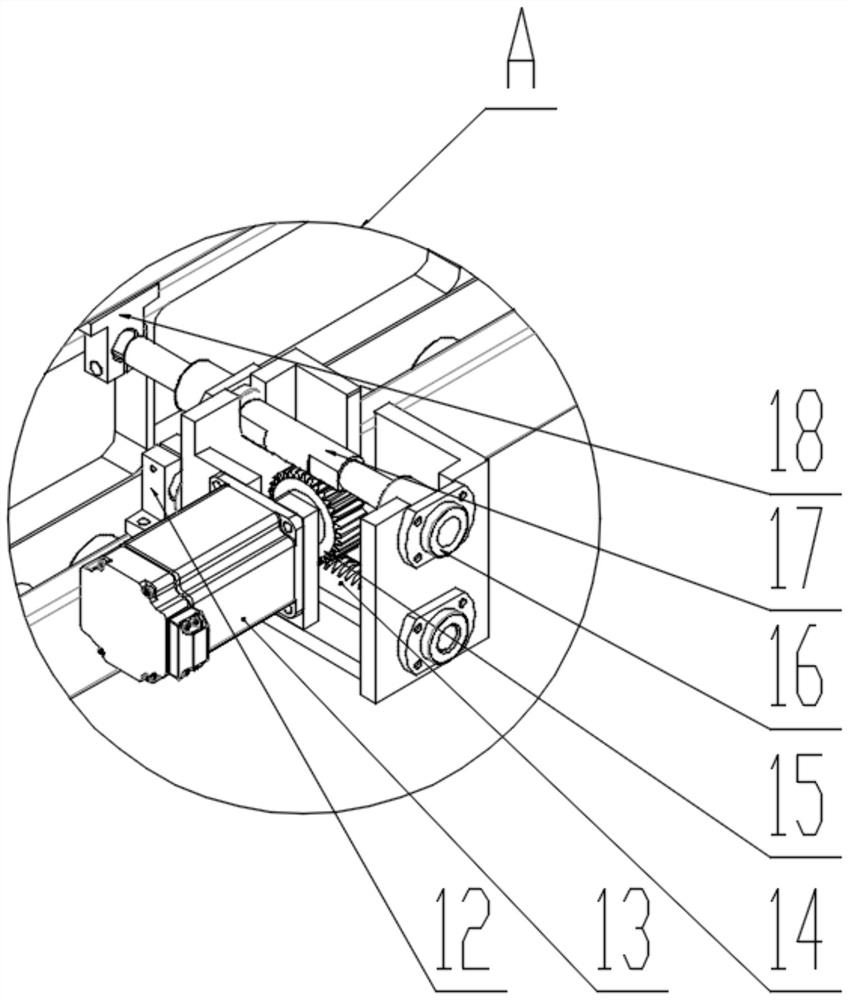

[0031] The present invention provides such Figure 1-4 A new drop-type empty frame conveying device shown includes a frame 3, the top of the frame 3 is fixedly connected with a guide groove 2, and one end of the guide groove 2 is rotatably installed with a transition electric drum 1, and the machine Both sides of the inner top of the frame 3 are provided with an upper material receiving plate 7, and both sides of the inner middle part of the frame 3 are provided with a lower material receiving plate 10, and the two lower layer material receiving plates 10 are respectively located at the two upper layers. At the bottom of the material plate 7, the frame 3 is fixedly equipped with an upper guide rod 8 near the position of the upper layer material r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap