Oral liquid bottle separating device for oral liquid production line and oral liquid production process

A technology of oral liquid and production line, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, complex structure, investment cost and production cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

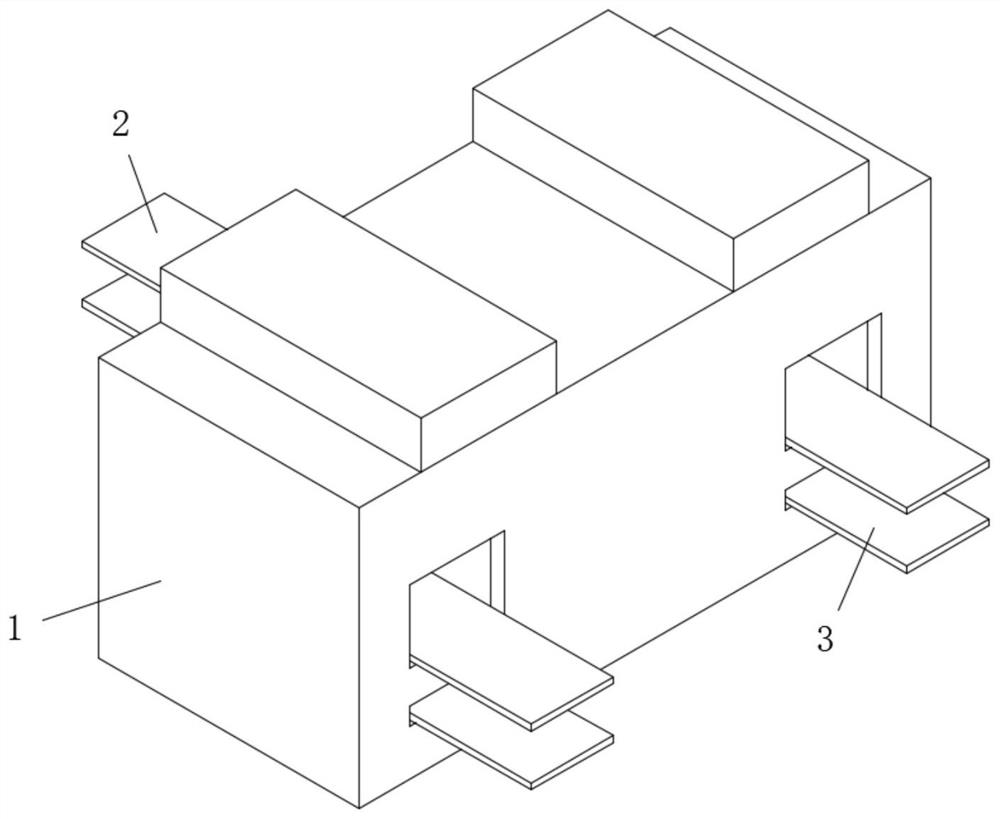

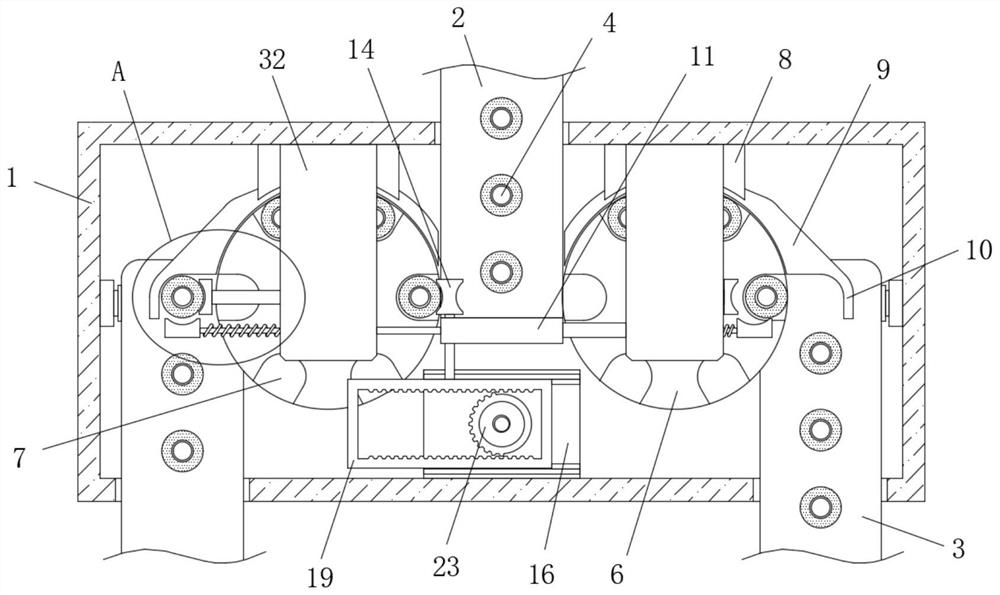

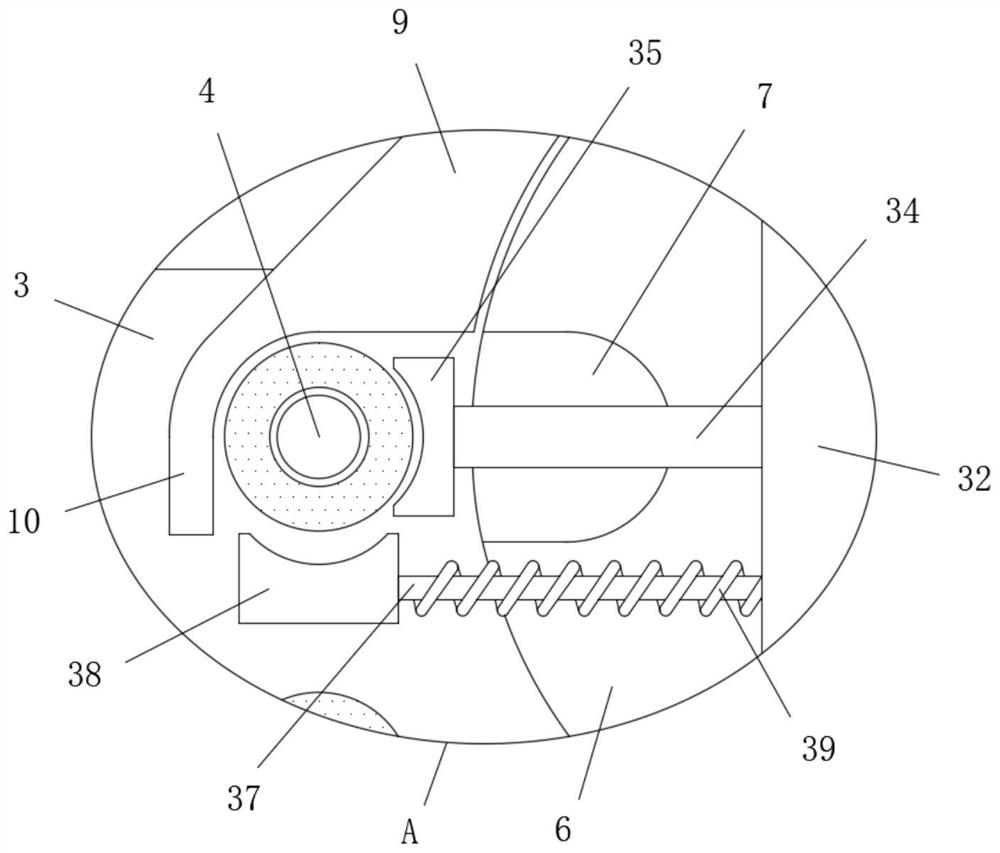

[0038] refer to Figure 1-11 , an oral liquid bottle channeling device for an oral liquid production line, comprising a cover body 1, a main conveyor belt 2 runs through one side of the cover body 1, and two branch conveyors run symmetrically through the side of the cover body 1 away from the main conveyor belt 2 Belt 3, and the both sides of main conveyer belt 2 and two branch conveyer belts 3 extend to the inside and the outside of cover body 1 respectively, the top of main conveyer belt 2 and two branch conveyer belts 3 all convey bottle body 4, cover The inner wall of the bottom of the body 1 is symmetrically provided with two sets of lane components, the two sets of lane components are respectively located on both sides of the main conveyor belt 2 and are respectively matched with the two branch conveyor belts 3, and the cover body 1 is close to one side of the main conveyor belt 2. Two groups of protective components are arranged symmetrically on the inner wall of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com