Splitting device and roadway floor pressure relief method

A technology of roadway and floor, which is applied in earth-moving drilling, surface mining, underground mining, etc., can solve the problems of inability to operate in parallel, difficult to handle, and large amount of engineering, so as to improve the splitting depth, shorten the operation time, and shorten the operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

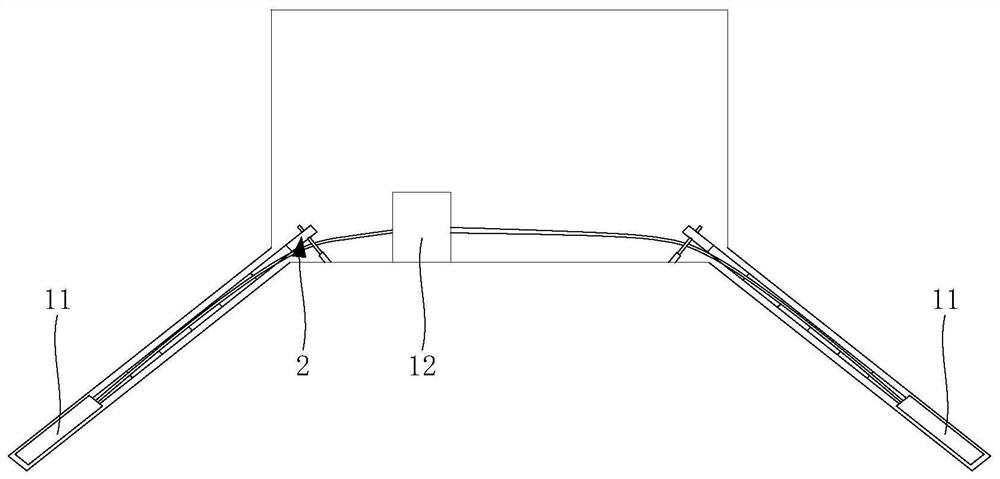

[0070] Such as Figure 4 As shown, a kind of roadway floor pressure relief method provided in this embodiment includes:

[0071] Step S101: using a drilling rig to drill holes at the two bottom corners of the roadway;

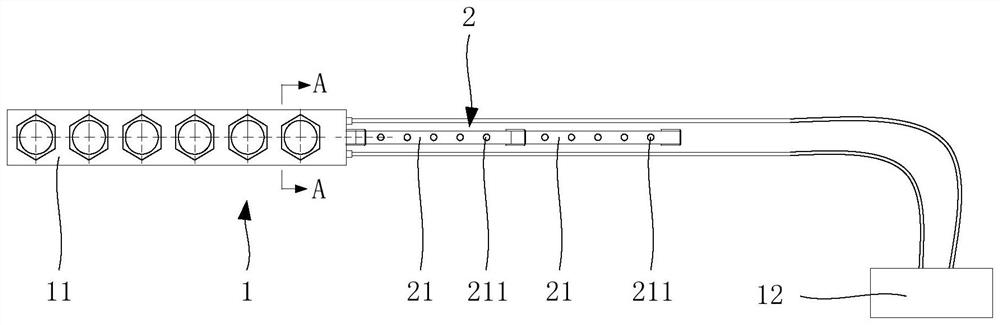

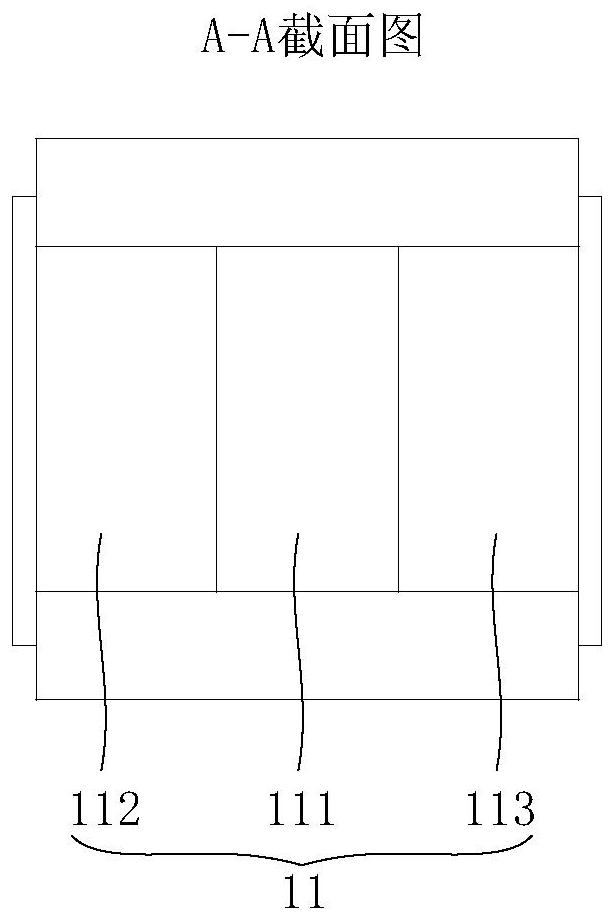

[0072] Step S1021: extending the hydraulic jack 11 in the splitting rod 1 into the bottom of the hole by adjusting the assembly 2;

[0073] Step S103: splitting the rock around the bottom of the hole by hydraulic jack;

[0074] Step S104: Shorten the distance between the hydraulic jack 11 and the hole opening by adjusting the component 2, and use the hydraulic jack to split the rocks around the hydraulic jack 11.

[0075] In order to describe the pressure relief method for the above-mentioned roadway floor more clearly, it can be specifically described as Figure 4 The method shown is described as an example. Such as Figure 4 As shown, first perform step S101 and use a drilling rig to drill holes at the two bottom corners of the roadway, with a hole diame...

Embodiment 2

[0077] Such as Figure 5 As shown, a kind of roadway floor pressure relief method provided in this embodiment includes:

[0078] Step S101: using a drilling rig to drill holes at the two bottom corners of the roadway;

[0079] Step S1021: extending the hydraulic jack 11 in the splitting rod 1 into the bottom of the hole by adjusting the assembly 2;

[0080] Step S1022: fixing the adjustment assembly 2 on the floor of the roadway;

[0081] Step S103: splitting the rock around the bottom of the hole by hydraulic jack;

[0082] Step S104: Shorten the distance between the hydraulic jack 11 and the hole opening by adjusting the component 2, and use the hydraulic jack to split the rocks around the hydraulic jack 11.

[0083] In order to describe the pressure relief method for the above-mentioned roadway floor more clearly, it can be specifically described as Figure 4 The method shown is described as an example. Such as Figure 4 As shown, first perform step S101 and use a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com