Electrophoresis tank system for steel wheel and electrophoretic coating method

An electrophoretic coating and electrophoretic tank technology, which is applied in the field of wheel manufacturing, can solve the problems of puncturing the anode film, affecting the quality of electrophoretic coating, and equipment damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

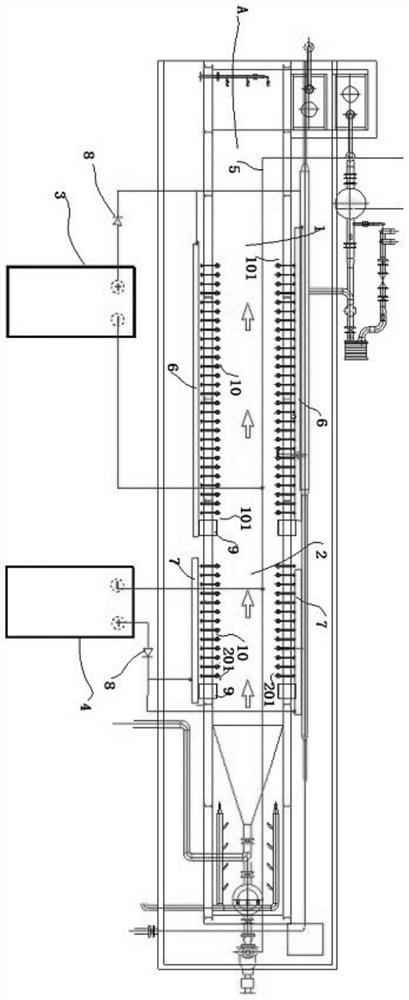

[0046] This embodiment provides an electrophoresis tank system for steel wheels, the specific structure is as follows figure 1 shown, including:

[0047] Tank body A for storing electrophoretic paint, high-voltage power supply 3 , low-voltage power supply 4 and electrophoretic device transportation part 5 .

[0048] The tank body A includes a low-pressure tank section 2 and a high-pressure tank section 1 connected together. The high-voltage tank section 1 is provided with a high-voltage anode structure 101, and the low-pressure tank section 2 is provided with a low-pressure anode structure 201. The tank body A is equipped with an inlet and outlet The import and export of electrophoretic paint (not shown in the figure), the positive pole of high-voltage power supply 3 is connected with high-voltage anode structure 101, and in the present embodiment, high-voltage power supply 3 is a high-voltage rectifier cabinet, and the voltage value provided is 160V~250V; The positive pole o...

Embodiment 2

[0054] This embodiment provides a method for electrophoresis steel wheels using the system of Embodiment 1, in which a steel wheel blank made of B530 main body is coated with a layer of epoxy-isocyanate paint film by electrophoresis.

[0055] Specific steps are as follows:

[0056] Step S1: Debug the distance between the bare anode of the high-voltage anode structure and the last anode unit of the low-voltage anode structure. The specific method of debugging is: after the equipment has been running for a week, take out the anode cover of the last anode unit of the low-voltage anode structure, Observe whether there are electrophoretic paint film particle deposits on the surface. If there are, it means that the electrodes of the high-voltage power supply and the electrodes of the low-voltage power supply form positive and negative electrolytic reactions in the electrophoretic paint. At this time, the distance needs to be increased by 0.2 times the width of the bare anode. Subseq...

Embodiment 3

[0061] This embodiment provides a method for electrophoresis steel wheels using the system of Embodiment 1. A steel wheel blank made of (B530) main body is coated with a layer of epoxy-isocyanate paint film by electrophoresis.

[0062] Adopt the production method of the S2-1 model product in Example 2, the only difference is that in step S1, the debugging is carried out with 0.3 times the width of the bare anode, the number of debugging is 5 times, and the minimum distance of the debugging is 560mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com