Novel airport fabricated pavement flexible transition layer system and method

A prefabricated, transition layer technology, applied in roads, roads, road repair and other directions, can solve the problems of difficult control of grouting amount and pressure, long adjustment period, difficult control, etc. The effect of improving accuracy and meeting waterproof requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

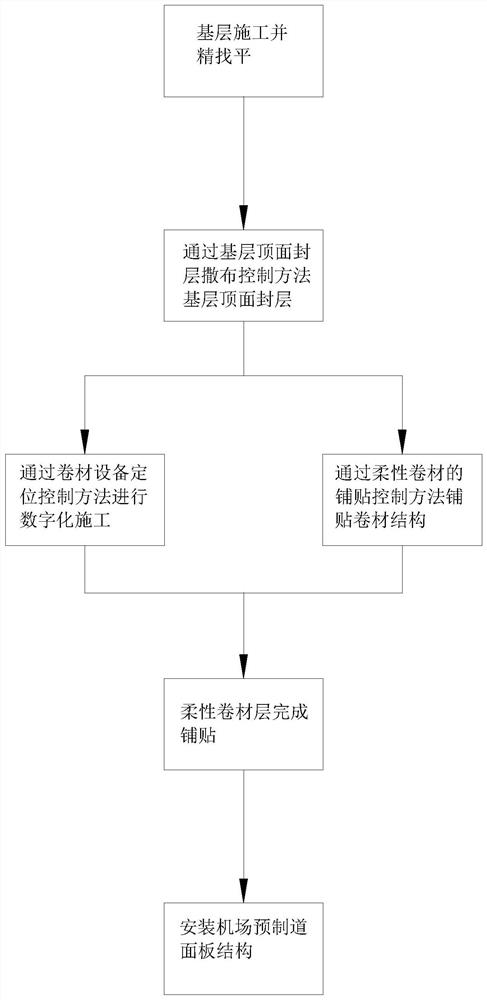

[0043] combine Figure 1 to Figure 4 , a new airport assembly-type pavement flexible transition layer system and method, including an airport pavement base layer 1, and the airport pavement base layer 1 is used to seal the top surface of the airport pavement base layer through a method for controlling the spreading of the base layer top surface seal layer, And the flexible coiled material board 2 is laid on the top surface seal layer of the base course of the airport road by means of the coiled material equipment positioning control method and the flexible coiled material paving control method, and then the concrete prefabricated road panel 3 is laid on the flexible coiled material board 2 .

Embodiment 2

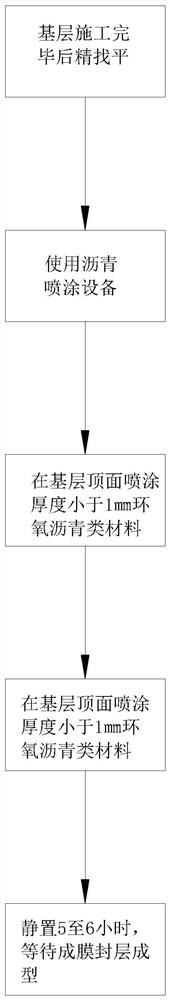

[0045] combine Figure 1 to Figure 4 A novel airport assembly pavement flexible transition layer system and method, comprising an airport pavement base layer, wherein the airport pavement base layer is sealed on the top surface of the airport pavement base layer by a control method for top surface sealing layer spreading of the base layer. The spreading control methods of the base layer top surface seal layer include the following:

[0046] Step A1, after the construction of the base layer is completed, the base layer is further finely leveled, and then the epoxy asphalt material is evenly spread on the top surface of the base layer using asphalt spraying equipment, and the film thickness of the asphalt spraying is ≤1mm;

[0047] Step A2, using the digital automatic control system of the asphalt spraying equipment to scrape the top surface of the film-forming seal layer, with a flatness of ≤2mm / 3m;

[0048] In step A3, after the flattening control of the film-forming sealing ...

Embodiment 3

[0050] combine Figure 1 to Figure 4 , a new airport assembly type pavement flexible transition layer system and method, including the base layer of the airport road, the top surface of the base layer of the airport road is sealed by the top surface sealing layer spreading control method of the base layer, and the base layer of the airport road is sealed by Coil equipment positioning control method.

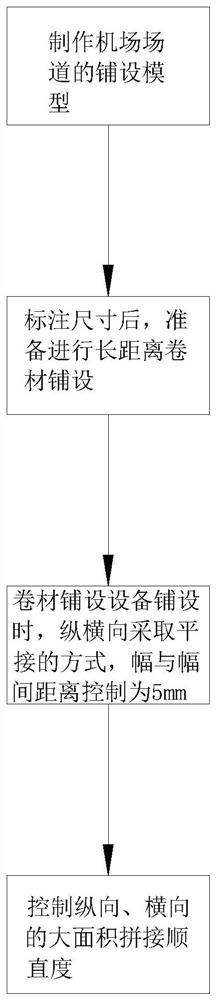

[0051] Coil equipment positioning control methods include the following:

[0052] Step B1, making a laying model: using 3D digital positioning equipment and 3D production software to form a model of flexible coiled material boards laid on the airport track;

[0053] Step B2, after dimensioning the model made by the 3D production software, the coil laying equipment performs long-distance coil laying;

[0054] Step B3, when the coil laying equipment is laid, the vertical and horizontal joints are adopted, and the distance between the webs is controlled to 5mm;

[0055] In step B4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com