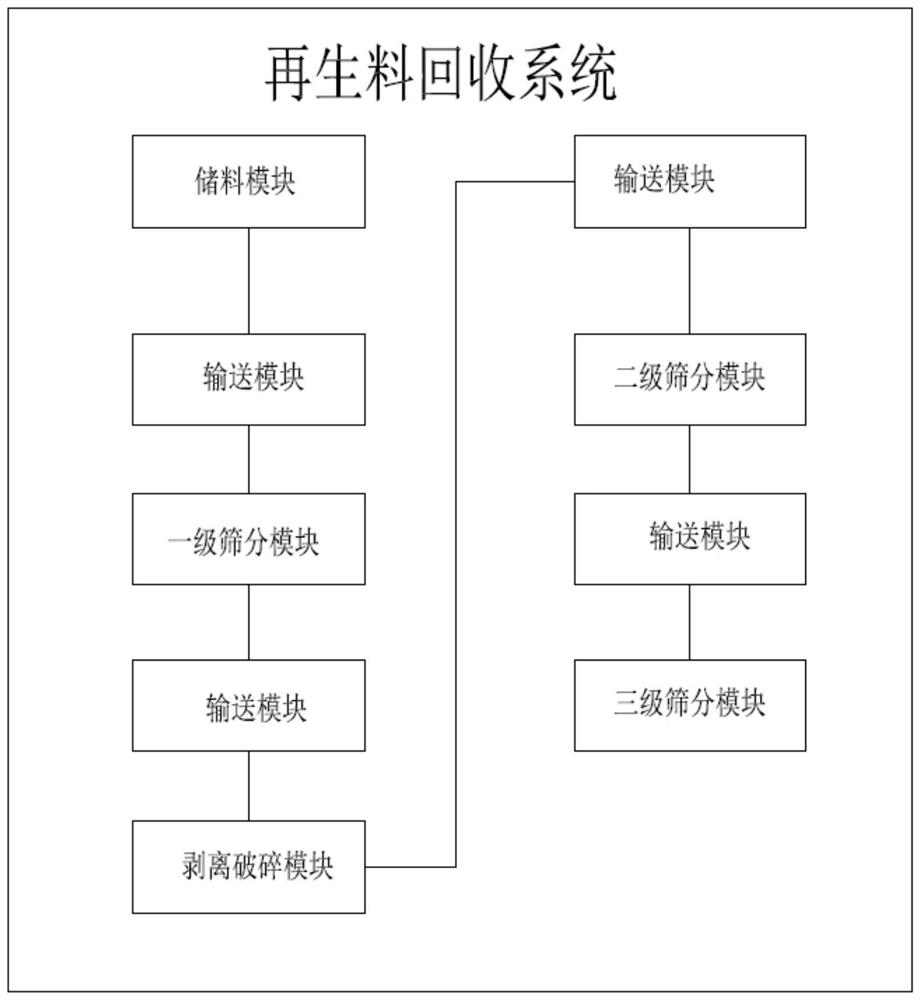

Asphalt concrete reclaimed material recovery system and recovery method

A technology of asphalt concrete and recovery system, which is applied in roads, road repairs, roads, etc., can solve the problems of high viscosity of materials and high agglomeration rate, and achieve the effect of reducing agglomeration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] refer to figure 2 , put the asphalt concrete to be screened in the silo, and transport it to the cold vibrating screen through the belt conveyor. The belt conveyor is controlled by frequency conversion and equipped with vibration arch breaking, which can effectively prevent the asphalt concrete from arching during the conveying process. Primary screening of asphalt concrete by cold vibrating sieve can screen out asphalt concrete with a particle size greater than 40mm. Asphalt concrete with a diameter of less than 40mm can be transported to the hoist through the belt conveyor, and then transported to the stripping crusher through the hoist, and the asphalt concrete will be rotated and broken evenly by the stripping crusher, and the excess asphalt in the asphalt concrete will be stripped. Specifically, reduce The asphalt content attached to the asphalt concrete with a particle size greater than 5mm, while increasing the asphalt content attached to the asphalt concrete wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com