Cement floor support plate and manufacturing method thereof

A floor deck and cement technology, which is applied in the direction of floor slabs, structural elements, building components, etc., can solve the problems of metal parts affecting the project quality and living comfort, prolonging the construction period, and high cost of production equipment, so as to solve the difficulties in the construction of equipment and pipelines , reduce labor intensity, reduce the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

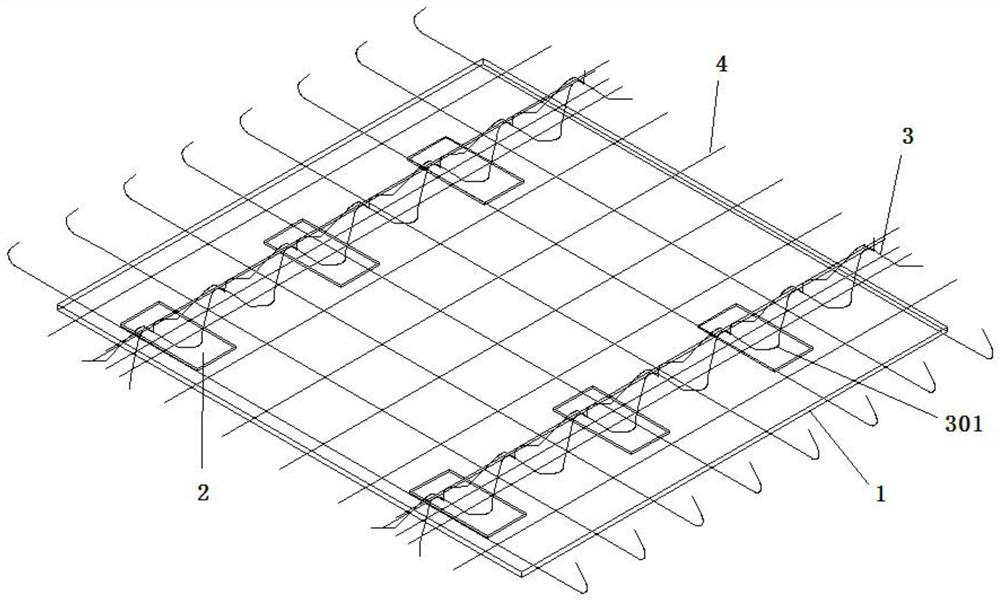

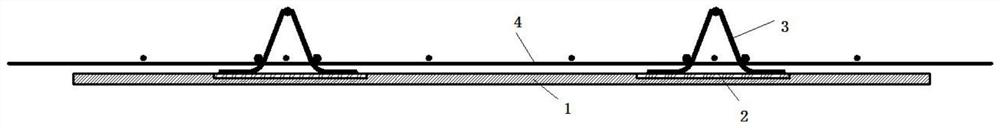

[0039] like Figure 1-4 As shown, the present embodiment proposes a cement building plate, including a bottom template body 1, a bottom template body 1, and a partial burn steel plate 2 or a partially having a plurality of pre-buried steel plates 2, the upper surface of the pre-buried steel plate 2 is exposed to the outside world. , As the weld base surface; the lower surface of the pre-buried steel sheet 2 is inserted inside the bottom template body 1; the upper surface of the pre-buried steel sheet 2 may be higher or lower than the upper surface of the bottom template body 1, or it can be flat. It is preferred to adopt a tempered mode.

[0040] like Figure 5-8 As shown, the pre-buried steel sheet 2 includes, but is not limited to, a strip, a rectangular block or a whole panel structure; wherein the bottom template body 1 has an embedded steel plate 2, the pre-buried steel plate 2 is a whole panel structure; when the pre-buried steel plate 2 is When the rectangular block is shaped...

Embodiment 2

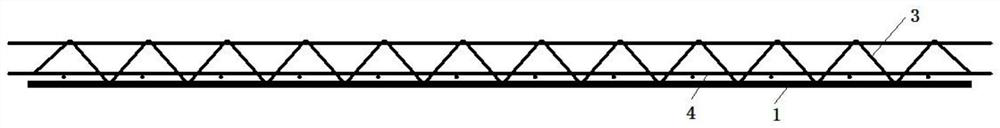

[0043] Continue reference Figure 1-8 In this embodiment, a cement building is proposed. The floor panel contains the above-mentioned bottom template; the bottom template is a bottom template with a pre-buried steel sheet in the first embodiment; and a multi-set longitudinally set steel truss 3, The reinforcing truss 3 includes a set of upper string steel 31, two sets of lower string steel 32; between the upper string steel 31 and the lower string steel 32 are welded to be integrated by the wavy belly reinforcing bar 33, forming a three-dimensional structural truss having a triangular shape of the end surface; steel truss 3 connection There is a steel mesh 4; the reinforced truss 3 and the steel mesh 4 are welded as a whole with the embedded steel plate 2.

[0044] The steel mesh 4 is welded by longitudinal steel bars and transverse steel bars; the longitudinal steel bars extend to the end template body 1 in the end of the longitudinal steel bar to the bottom template body 1. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com