Separation device and separation method for gas, water and coal slag in coal mine gas extraction pipeline

A coal mine gas and separation device technology, which is applied in the direction of gas discharge, safety devices, drainage, etc., can solve problems that affect the drainage effect, complex structure, and blockage of the drainage pipeline, so as to improve the efficiency of gas drainage and the overall structure is simple , to ensure the effect of the pumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

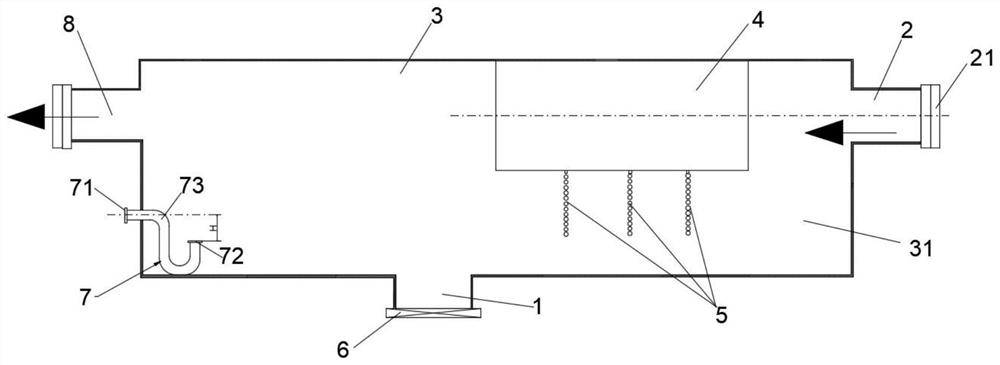

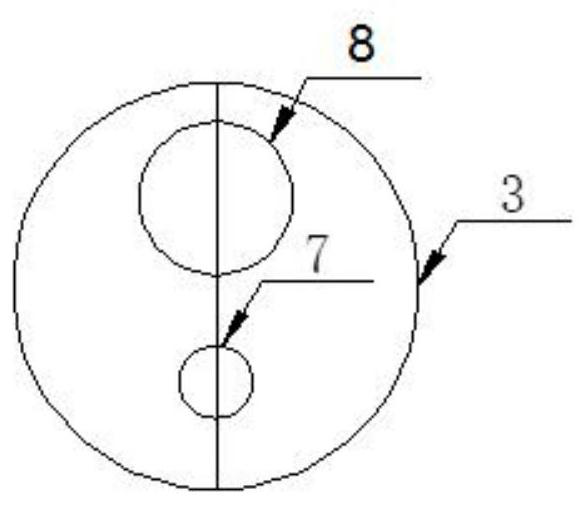

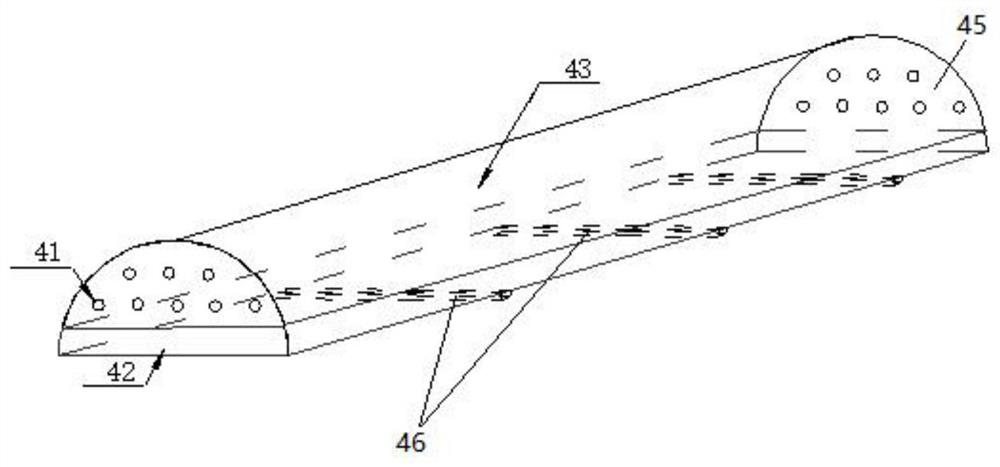

[0043] Example 1, such as Figure 1-5 As shown, a coal mine gas extraction pipeline gas, water, coal slag separation device, including

[0044] The water slag storage 3, the inlet pipe 2 and the outlet pipe 8 of the water slag storage 3 are provided with a gas, water and coal slag separator 4 in the storage chamber 31 of the slag storage 3; the mixed gas containing water and coal slag passes through The inlet pipe 2 is discharged into the storage cavity 31, the gas, water and cinder separator 4 separates gas, water and cinder from the mixed gas, and the gas after separation is processed by the The outlet pipe 8 is discharged; a slag discharge pipe 1 is provided at the bottom of the cavity of the water slag storage 3, and a slag discharge valve 6 is provided on the slag discharge pipe 1 to discharge the separated coal slag;

[0045] It also includes an automatic drainage device 7, the automatic drainage device 7 is arranged at the bottom of the storage chamber 31 at one end of...

Embodiment 2

[0058] Embodiment 2, the present invention also provides the gas, water, and cinder separation method of the coal mine gas extraction pipeline gas, water, and cinder separation device, including the following steps:

[0059] Step 1. Discharging the mixed gas containing water and coal slag into the water slag storage 3 through the inlet pipe 2 of the water slag storage 3, the extraction negative pressure of the mixed gas is generally not lower than 13KPa;

[0060] Step 2. The gas flow of the mixed gas is separated from gas, water and cinder through the gas, water and cinder separator 4 in the storage chamber 31 of the water slag storage 3. The specific gas, water and cinder separation steps include:

[0061] A: The first separation of gas, water and cinder: when the water and cinder with a diameter greater than 1-2mm in the mixed gas enter the large-diameter storage chamber 31 from the small-diameter inlet pipe 2, due to the sharp decrease in wind speed, the Gas cinder separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com