Wind turbine generator blade and bearing crack monitoring system

A technology for wind turbines and monitoring systems, which is applied in the monitoring of wind turbines, wind turbines, motors, etc., can solve the problems of high requirements for application scenarios, large limitations, and limited installation space, so as to facilitate the transmission of antenna signals and realize monitoring. Feedback and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

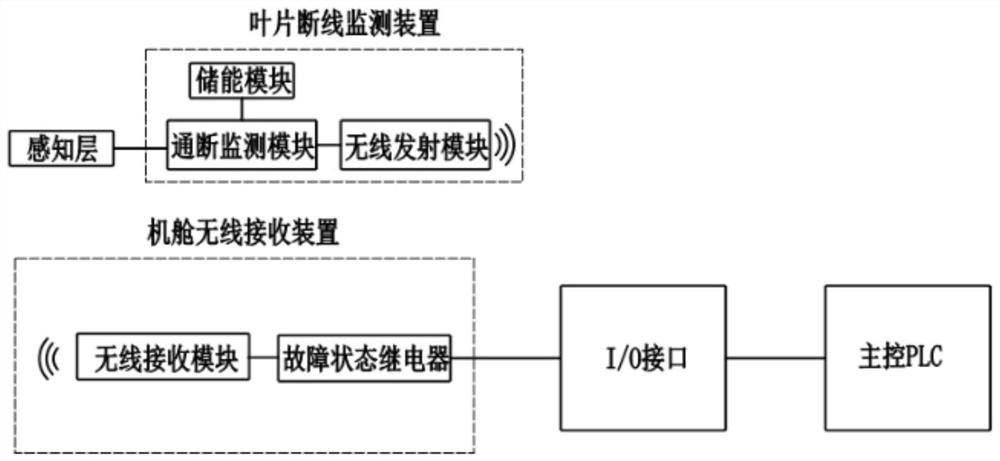

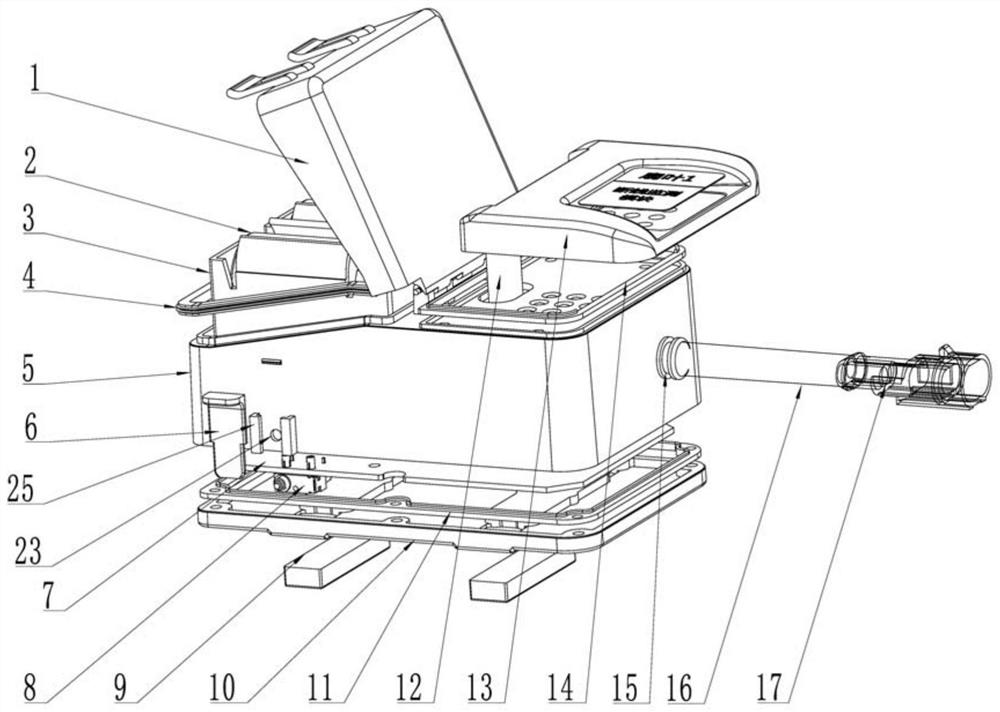

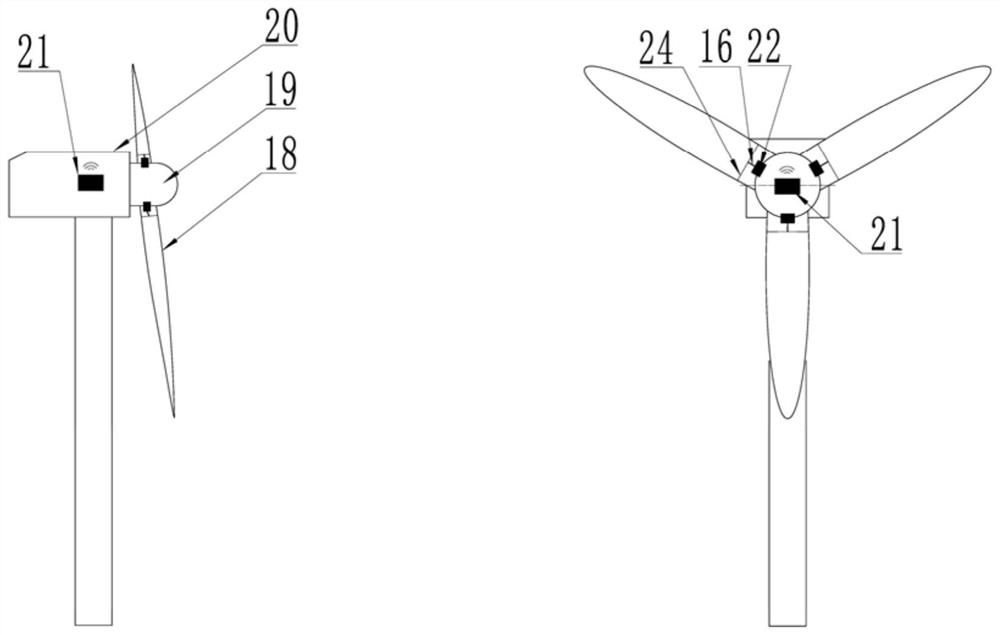

[0022] This embodiment provides a monitoring system for wind turbine blades and bearing cracks, combined with Figure 1 to Figure 4 , including at least a sensing layer 24 and a wire breakage monitoring device 22 installed on the peripheral outer wall of the root of the blade 18, the two are connected by a wire 16, the sensing layer is an insulating enameled wire sensor, and the sensing layer is bonded on the peripheral outer wall of the blade root by glue , the bottom of the disconnection monitoring device is provided with a magnet, and the disconnection monitoring device is fixed on the peripheral outer wall of the blade root connected to the hub 19 through a magnet 9, and is also provided with a wireless receiving device 21 and an I / O interface, and the disconnection monitoring device It includes a housing and an energy storage module installed in the housing, an on-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com