Friction-Optimized Vacuum Orbiter Pump

A technology of aircraft and vacuum pump, which is applied to components of pumping devices for elastic fluid, rotary piston type/swing piston type pump components, pumps, etc., can solve serious problems and achieve the effect of improving frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

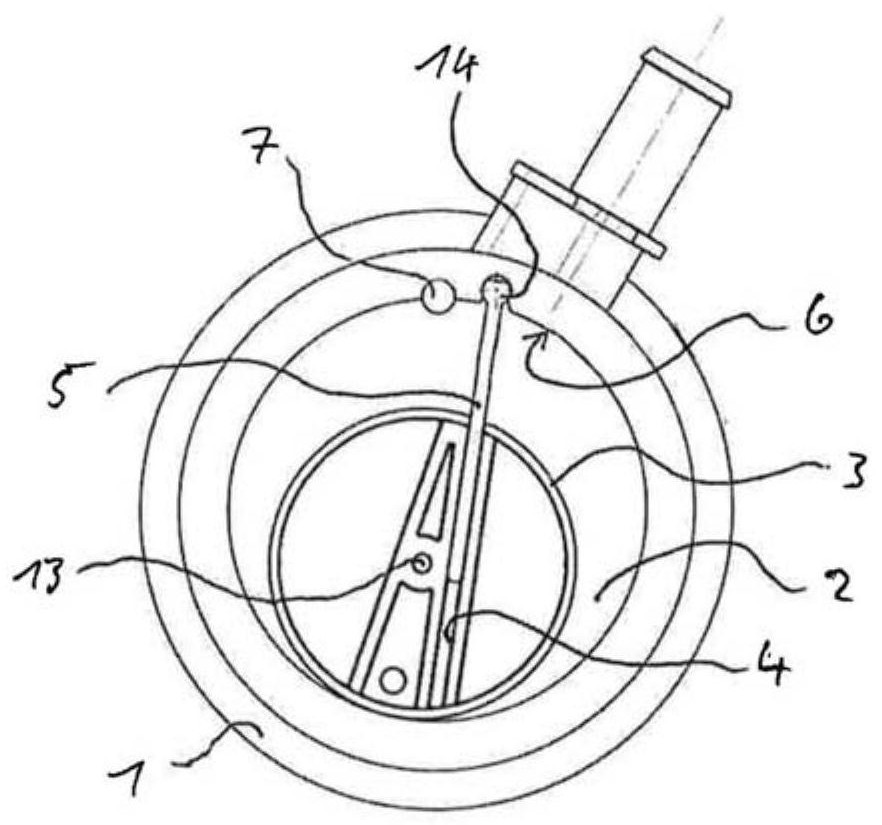

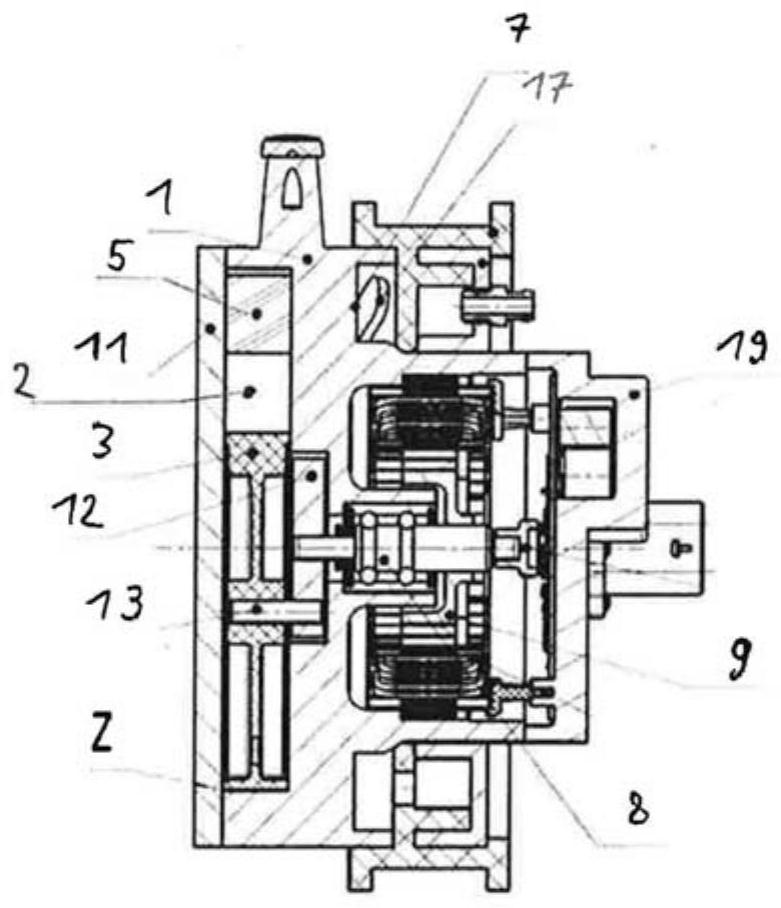

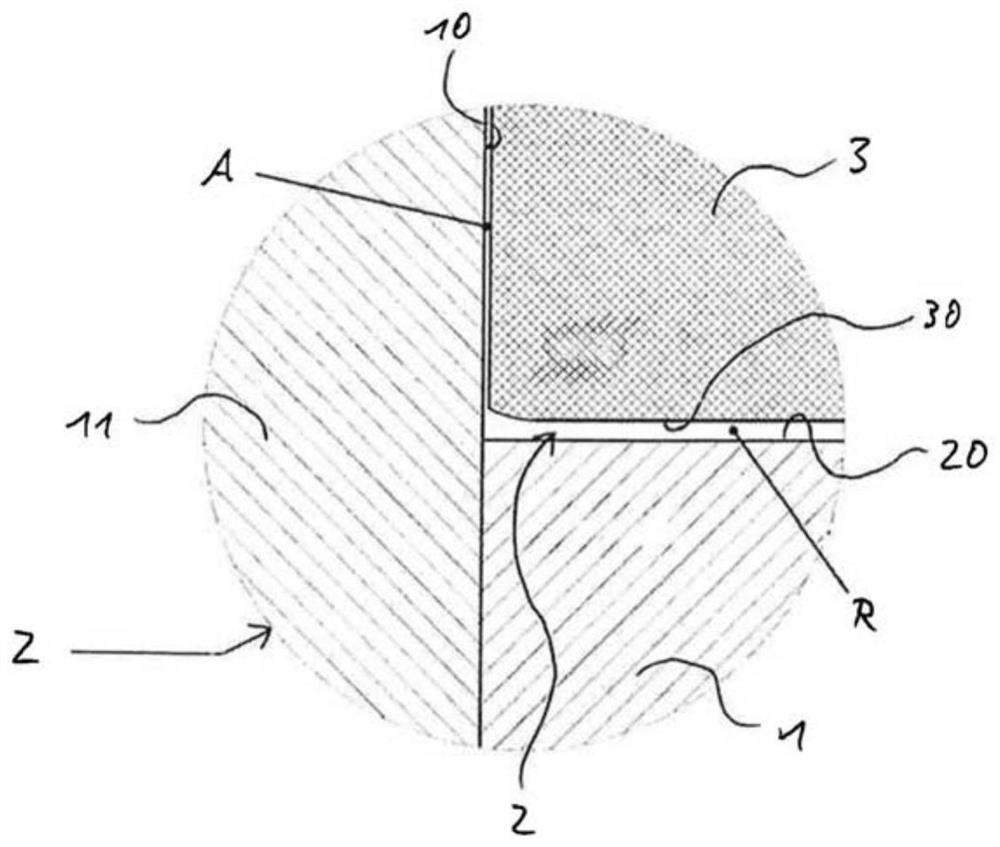

[0056] Such as figure 1 As shown, an orbiter vacuum pump according to an embodiment of the invention is formed by a pump housing 1 comprising a pump chamber 2 with cylindrical chamber walls. In the pump cavity 2, the orbiter eccentric piston 3 performs a circular movement, wherein the orbiter eccentric piston 3 is in circumferential sliding contact with the cavity wall. In the orbiter eccentric piston 3 there is provided a guide groove 4 in which a blocking slide 5 is slidably received. A blocking slide 5 extends through the pump cavity 2 into the orbiter eccentric piston 3 and is pivotally mounted at the free end. For this purpose, a pivot bearing 14 is provided in the cavity wall between the inlet opening 6 and the outlet opening 7 . The inlet of the pump has a nozzle for connecting a vacuum hose.

[0057] Depending on the position of the orbiter eccentric piston 3 in the circular movement in the pump chamber 2 , a part of the blocking slide 5 located opposite the pivotab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com