Mechanical seal cooling structure, high-temperature hot water circulating pump with mechanical seal cooling structure and method

A technology of cooling structure and high-temperature hot water, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of poor cooling effect of high-temperature circulating pumps, etc., to solve the problems of poor cooling effect, The effect of extending the cooldown time and strengthening the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

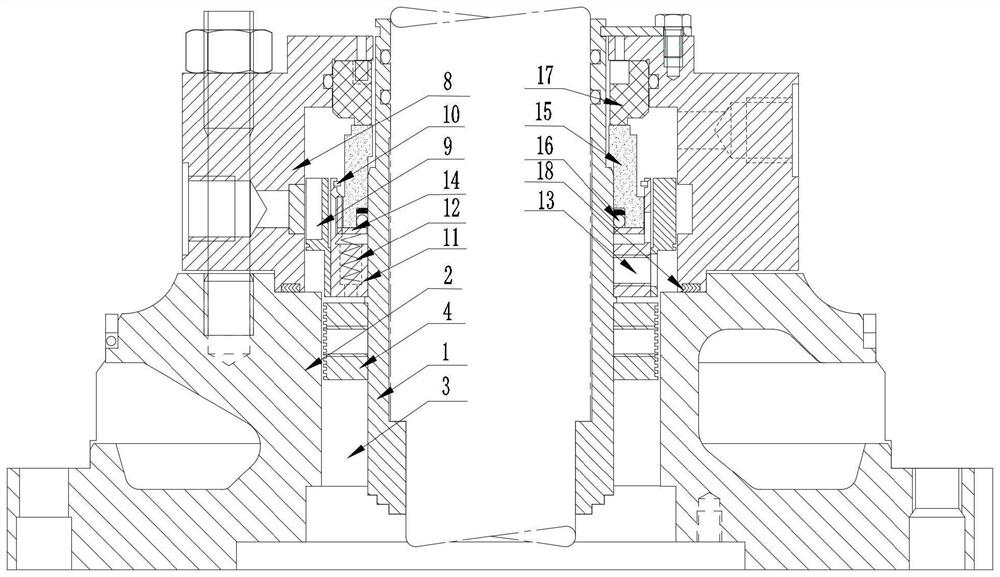

[0054] A mechanical seal cooling structure applied to high temperature hot water circulating pumps, wherein, such as figure 1 As shown, it includes: shaft sleeve 1, connecting seat 2, throttle ring 4.

[0055] The connecting seat 2 is sheathed on the shaft sleeve 1, and there is a hot water chamber 3 for passing hot water between the connecting seat 2 and the shaft sleeve 1.

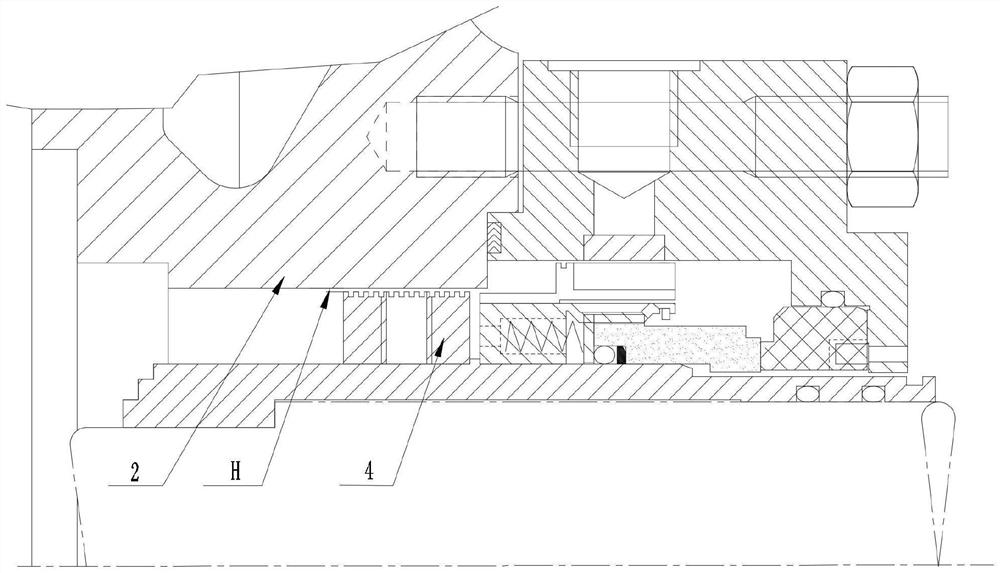

[0056] Such as Figure 1-3 As shown, the throttling ring 4 is located in the hot water chamber 3, and the throttling ring 4 divides the hot water chamber 3 into left and right parts. The flow gap H is connected, so that the high-temperature hot water flows through the hot water chamber 3, and is blocked by the throttle ring 4, and then the flow volume of the hot water is limited through the flow gap H so that the hot water is connected with the throttle ring 4 Seat 2 fully exchanges heat.

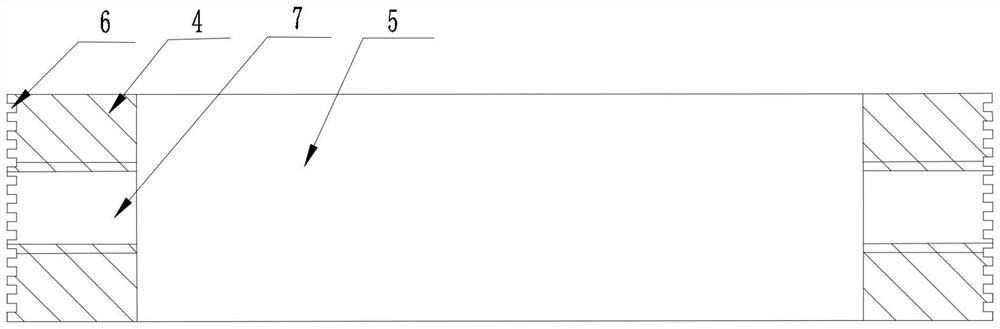

[0057] The throttle ring 4 has a casing hole 5 and a buffer cooling groove 6 , and the throttle ring 4 is sleeve...

Embodiment 2

[0072] A mechanical seal cooling structure, which is applied to high-temperature hot water circulating pumps, has the same characteristic structure as that of Embodiment 1, wherein, such as image 3 As shown, the ratio of the flow gap H formed by the outer end surface of the throttle ring 4 and the inner surface of the connecting seat 2 to the size of the hot water chamber 3 can also be set to 0.03:0.97. The size of the overcurrent gap H is 0.5mm or cm or dm or m.

[0073] After many tests, under the condition of high temperature hot water at 260°C, with this setting, after the high temperature hot water passes through the overflow gap H, its temperature will drop by about 150°C. And it is also found that this is the best choice found at present. If the size of the overflow gap H continues to be reduced, the problem of reducing the cooling effect on the mechanical seal may occur when the hot water is circulated (too little water flow for cooling flow) .

Embodiment 3

[0075] A high-temperature hot water circulation pump, which has the mechanical seal cooling structure in any one of the above-mentioned embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com