Vacuum pump one-way valve assembly

A one-way valve, vacuum pump technology, applied in the valve device, control valve, functional valve type and other directions, can solve the problems of inconvenient force-driven size adjustment control, poor opening and closing response efficiency, etc., to improve the force-driven response efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

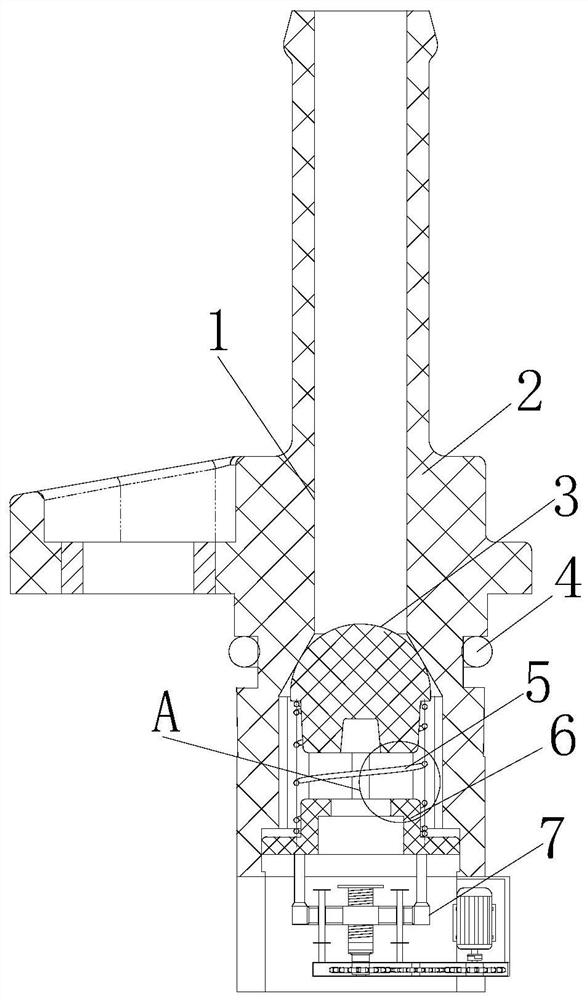

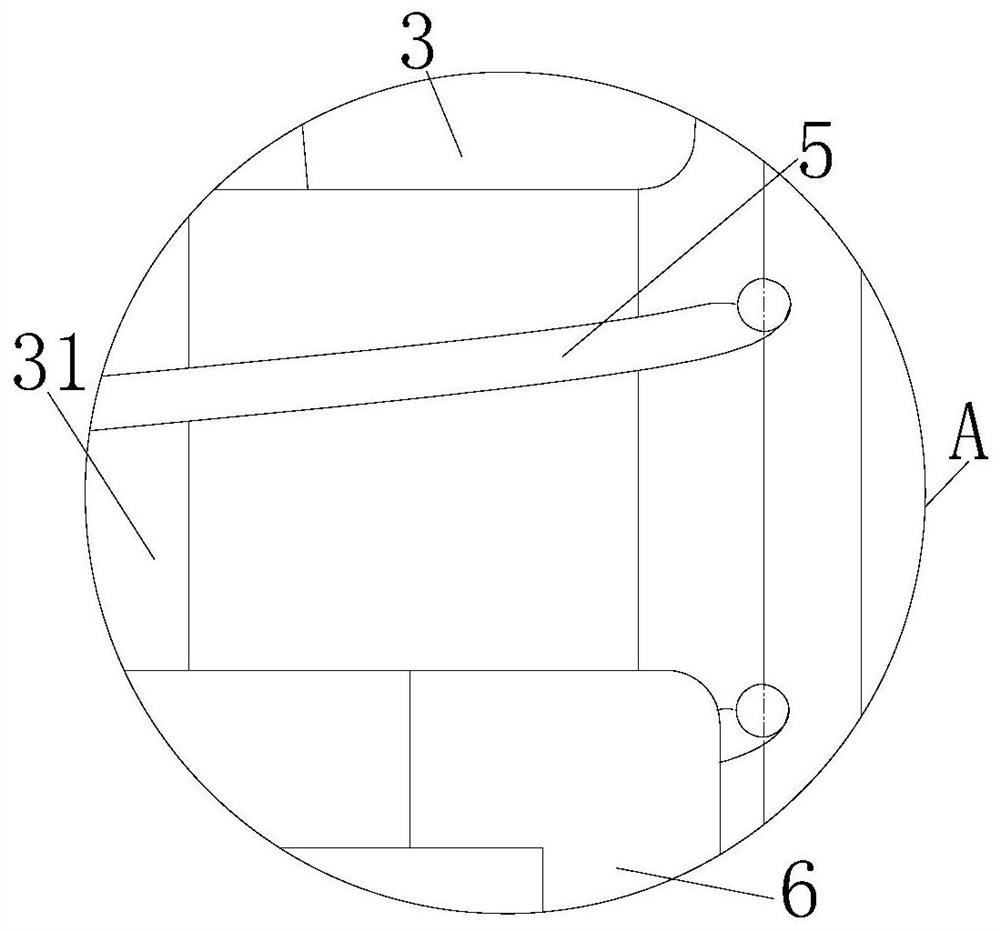

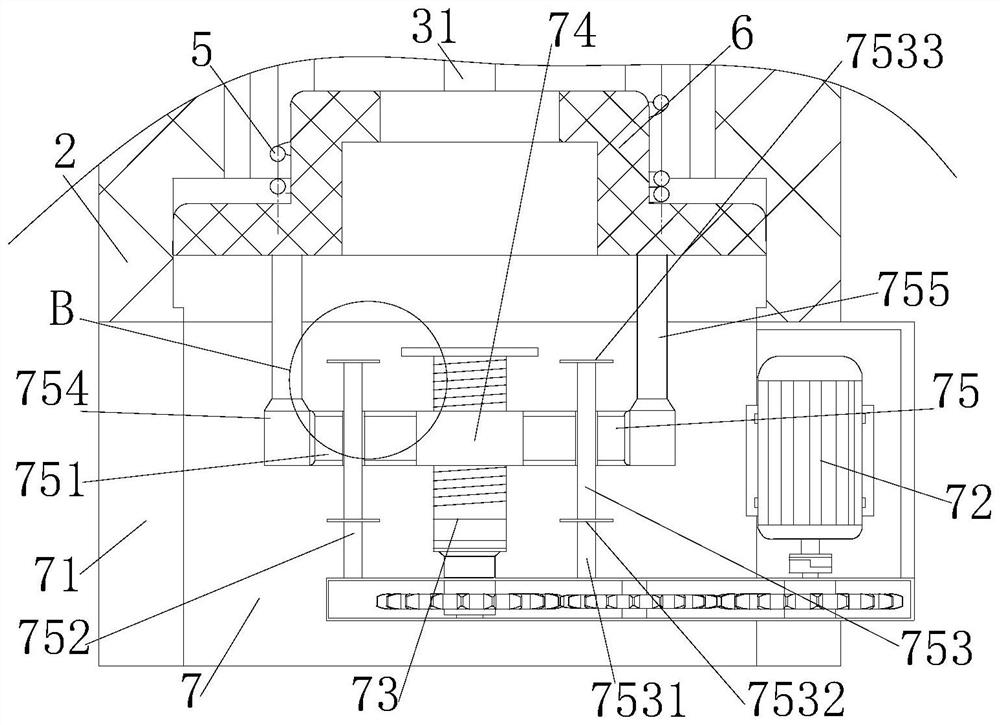

[0029] see figure 1 and figure 2 , a vacuum pump check valve assembly of the present invention, assembly main body 1, valve body 2, hemispherical valve core 3, O-shaped sealing ring 4, spring 5, valve seat 6 and adjustment structure 7, the air flow channel inside the valve body 2 The hemispherical valve core 3 is installed, and the outer middle side of the valve body 2 is connected with an O-ring 4. The outer surface of the bottom side of the hemispherical valve core 3 is in elastic contact with the valve seat 6 through the spring 5, and the valve seat 6 is slidably connected to the inner side of the valve body 2. The bottom side of the valve body 2 is connected with an adjustment structure 7, and the adjustment control is performed through the adjustment structure 7. A pillar 31 is embedded in the middle side of the bottom of the hemispherical valve core 3, and the bottom of the pillar 31 is inserted into the inner side of the valve seat 6 to fix it, and it plays a role of s...

Embodiment 2

[0032]A vacuum pump check valve assembly of the present invention, the bottom side of the hemispherical valve core 3 is provided with an inward inclination angle, the inner top side of the spring 5 is wrapped at the inclination angle of the bottom side of the hemispherical valve core 3, and the inner bottom side of the spring 5 is wrapped in the valve The outer surface of the top side of the seat 6 is supported by the spring 5 to provide elastic force for the hemispherical valve core 3. The channel opened inside the valve body 2 gradually increases from top to bottom, and the connection between the channel and the hemispherical spool 3 is conical. Table-shaped structure, the closedness after being adjusted is increased, the valve seat 6 is in a convex structure, and the valve seat 6 is arranged in a section of the chute on the bottom side of the valve body 2 and is longitudinally slidably connected with it, which is beneficial to the valve seat 6. The height position is adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com