Digging and anchoring all-in-one machine monitoring system based on digital twinning technology

A technology of monitoring system and all-in-one machine, which is applied in the direction of design optimization/simulation, etc. It can solve the problems of large impact on video image acquisition, unsatisfactory reliability and effect, and large dust concentration, so as to improve the effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

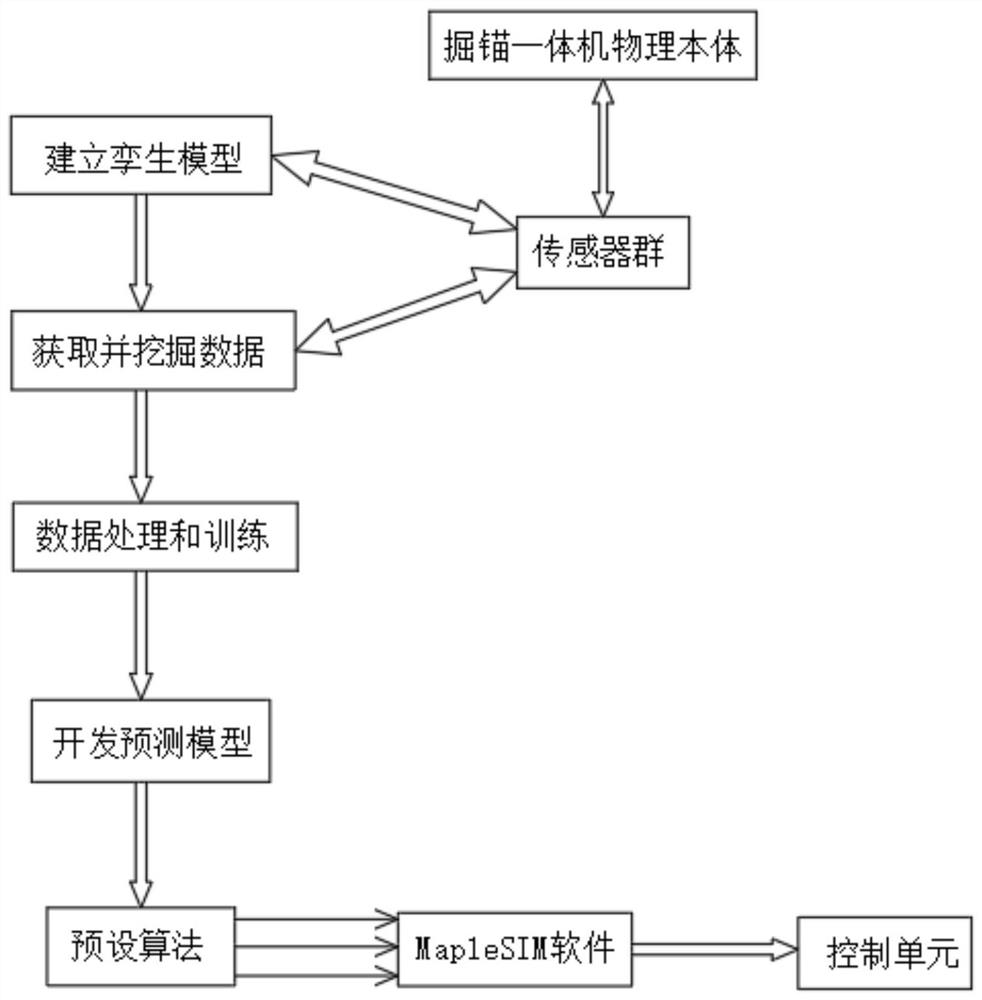

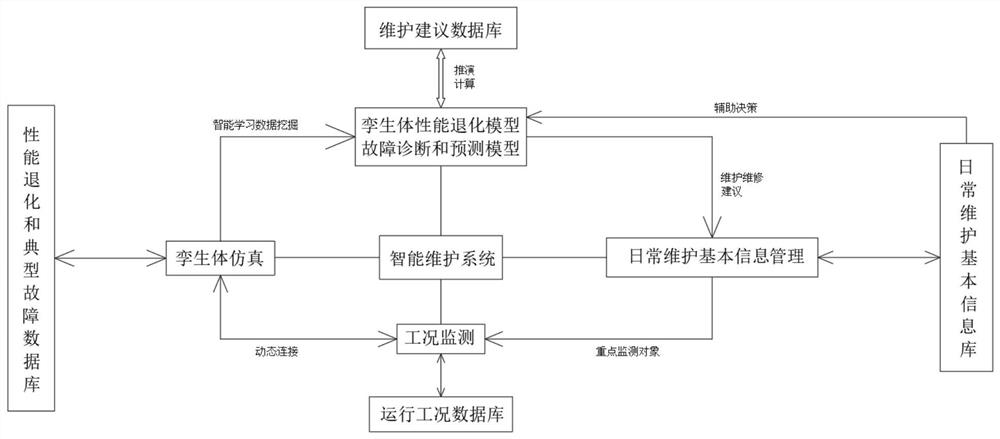

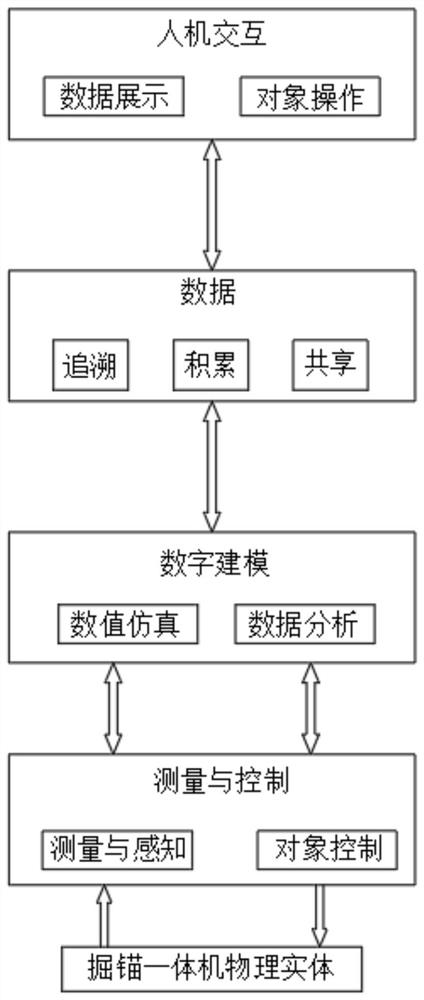

[0035] see Figure 1 to Figure 3 , an embodiment provided by the present invention: a monitoring system for a bolter mining integrated machine based on digital twin technology, comprising:

[0036] The physical body of the all-in-one machine for digging and bolting: the all-in-one machine for digging and bolting in mines, the work execution department is responsible for the normal operation of the bolting and digging work;

[0037] Sensor group: Distributed and fixedly installed on the physical body of the bolter digging machine, responsible for real-time collection of data related to the physical body movement of the bolter digging machine and real-time feedback dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com