Straw briquetting equipment for agricultural machinery

A technology of agricultural machinery and block equipment, applied in the field of straw briquetting equipment for agricultural machinery, can solve the problems of environment and operator injury, reduce work efficiency, etc., and achieve the effect of avoiding injury and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

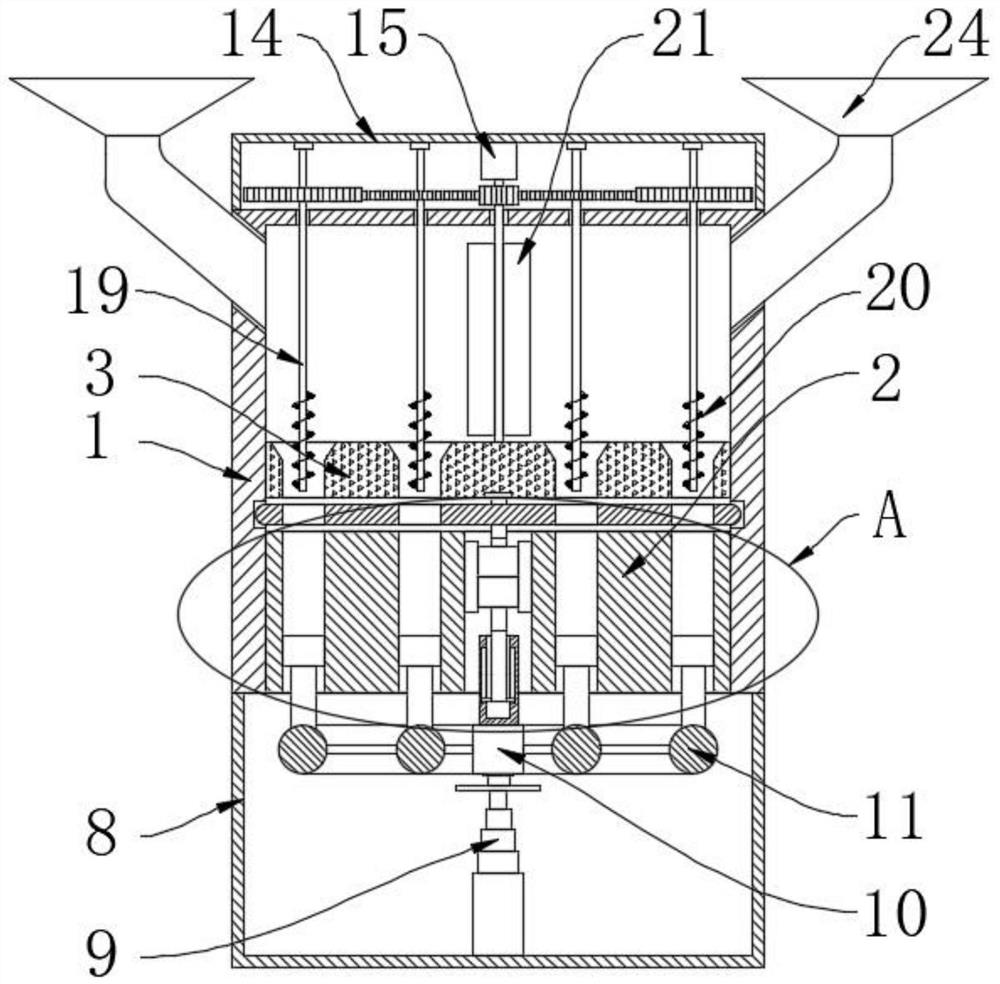

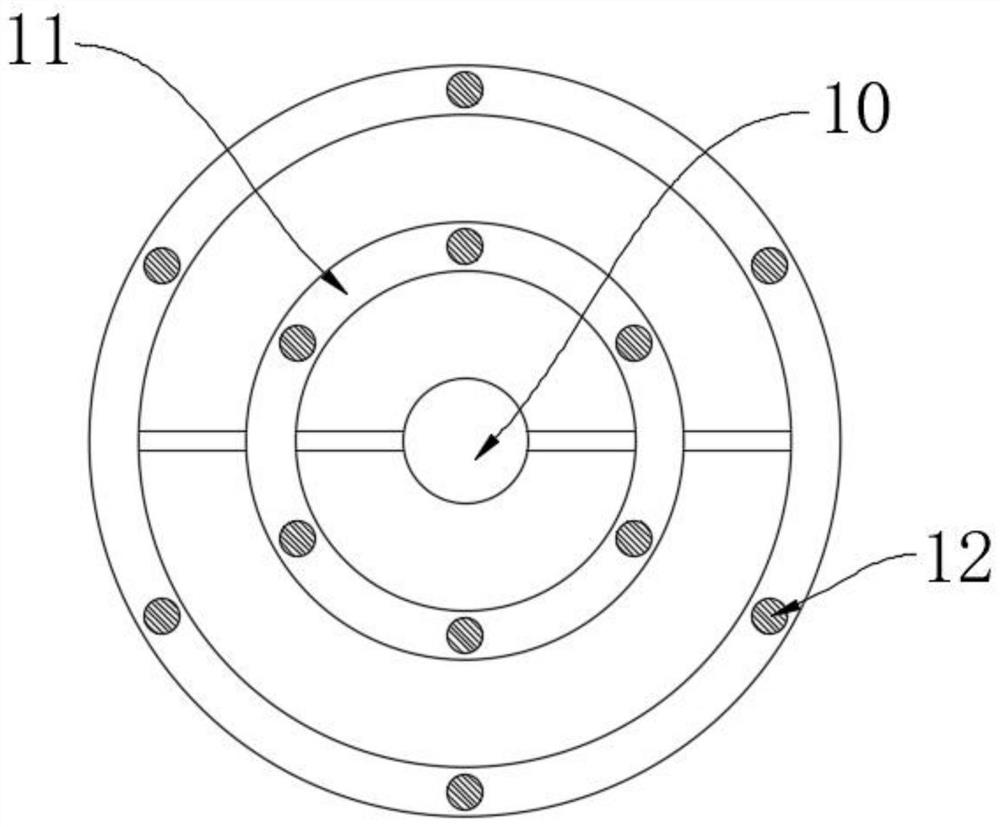

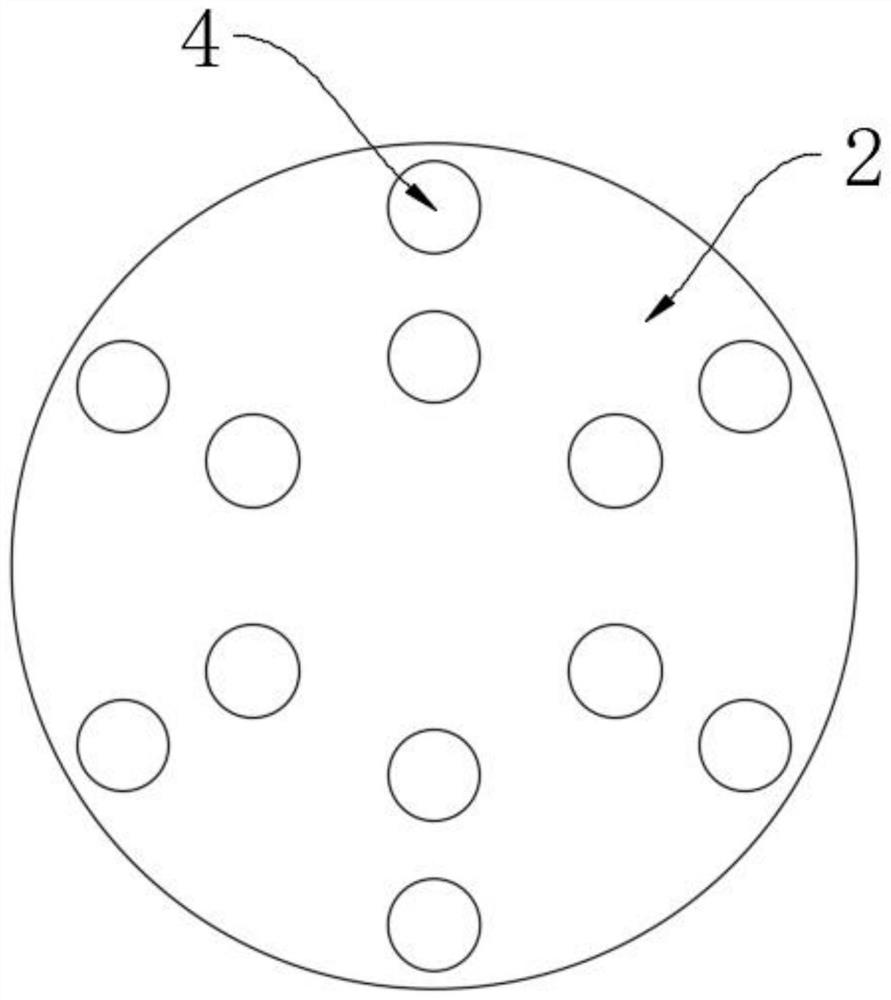

[0025] refer to Figure 1-4 , a kind of straw briquetting equipment for agricultural machinery, comprising an equipment box 1, the inner wall of the equipment box 1 is respectively fixedly connected with a mold 2 and a feeding tray 3, and the upper surface of the mold 2 is respectively provided with an installation opening and a plurality of briquetting holes 4 , the middle of the mold 2 and the feeding tray 3 is provided with a blocking disk 5, the upper surface of the blocking disk 5 is provided with a through hole matching the briquetting hole 4, and the blocking disk 5 rotates with the lower surface of the feeding disk 3 through the rotating shaft connection, the inner wall of the installation opening is fixedly installed with an upper motor 6 and a lower motor 7 respectively, the output end of the upper motor 6 is fixedly connected with the lower surface of the blocking plate 5, the lower surface of the equipment box 1 is provided with a fixed frame 8, and the fixed frame ...

Embodiment 2

[0030] refer to Figure 5-6 , different from Embodiment 1, the upper surface of the fixed box 14 is fixedly equipped with a dust collection box 16, the both sides surfaces of the equipment box 1 are all provided with feeding funnels 24, and the both sides surfaces of the dust collection box 16 are all embedded with A dust collection hood 25 compatible with the feed hopper 24 is provided with a dust collecting bag 26 at the gas outlet end of the dust collection hood 25, and a protective net 27 is provided at the top and bottom of the installation pipe.

[0031] The inner top wall of the dust collection box 16 is embedded with a mounting tube, the inside of the mounting tube is provided with a dust suction fan 17, the upper output end of the bidirectional motor 15 is fixedly connected with the main shaft of the dust suction fan 17, and the inner wall of the fixed frame 8 is rotated by a rotating shaft Two receiving frames 18 are connected.

[0032] The surfaces of the two recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com