Vacuum grabbing device of industrial robot and using method thereof

An industrial robot and grasping device technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of increasing man-hours and equipment categories, lack of versatility, and reducing production efficiency, achieving simple structure, improving production efficiency, Easy to assemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

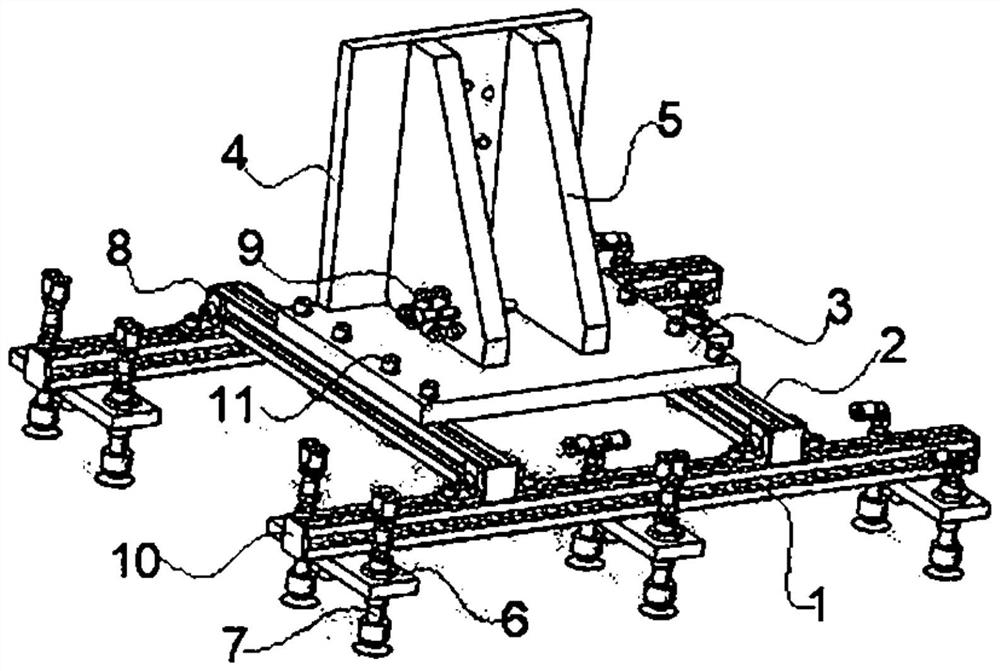

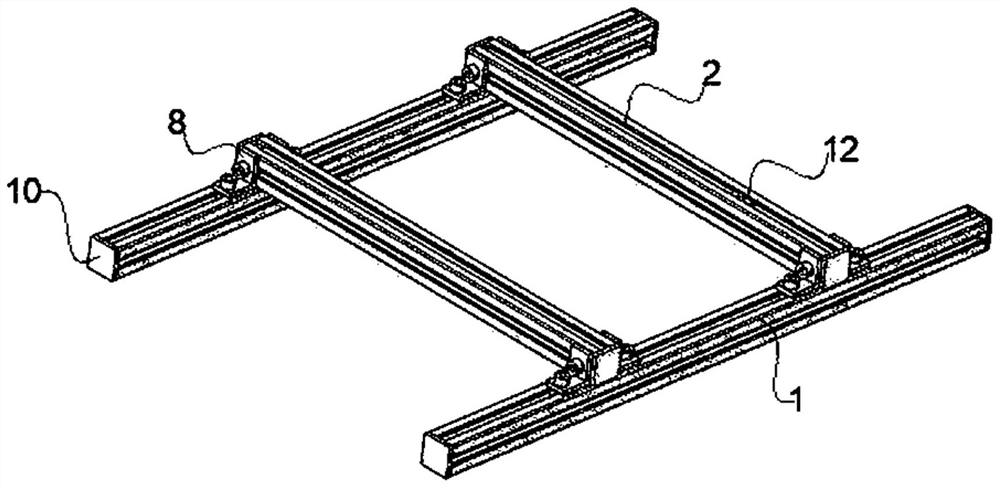

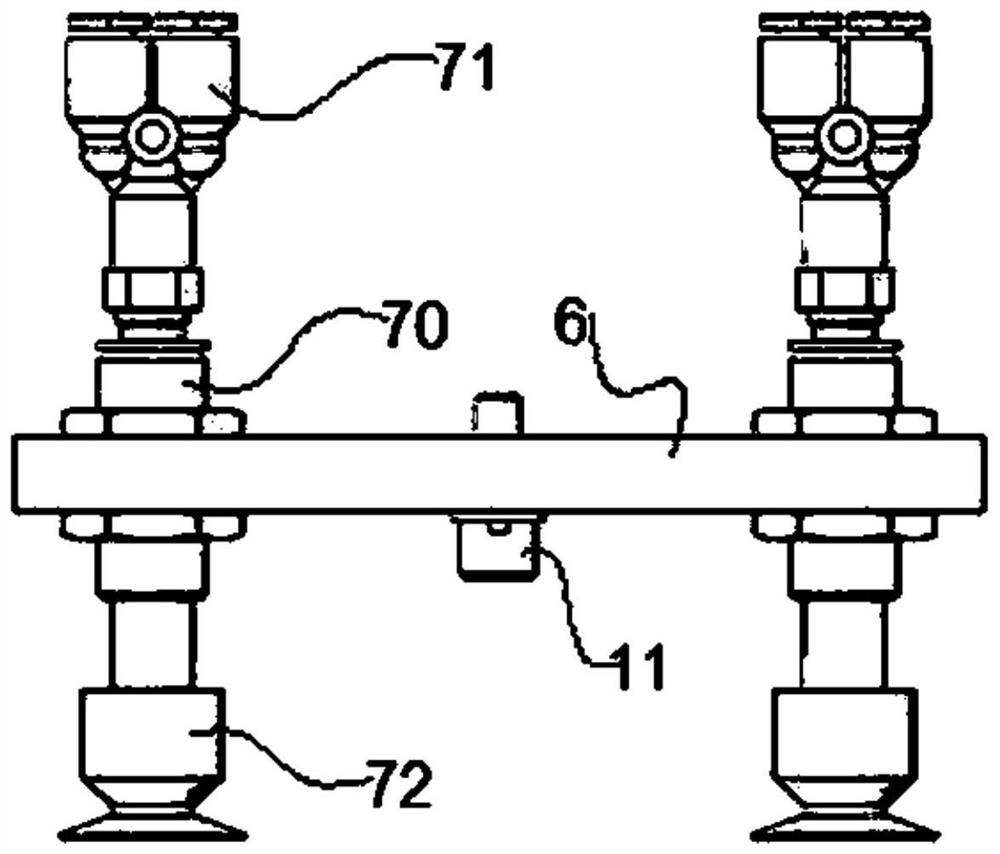

[0025] like Figure 1-3 As shown, the specific embodiment of the present invention: an industrial robot vacuum grabbing device and its use method, including the long slide rail 1 with the spacing between the left and right sides, the short slide rail 2 with the spacing between the front and rear sides, including the long slide rail 1. The short slide rail 2, the connecting frame 3 and the suction cup fixing frame 6 are characterized in that, the two ends of the short slide rail 2 are symmetrically installed with L-shaped brackets 8, and the short slide rail 2 and the long slide rail 1 pass through the L-shaped The bracket 8 is connected, and the short slide rails 2 are provided with two in total, and the top of the two short slide rails 2 is fixed with a connecting frame 3 by bolts 11, and the connecting frame 3 is connected to the connecting flange 4 through the rib plate 5 connection, the ribs 5 are provided with two groups in total, and the ribs 5 of the two groups are used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com