Lightweight attachment joint convenient to assemble and lift

A lightweight, chord technology, applied in the direction of cranes, pivot connections, etc., can solve problems such as lifting, installation in place, heavy weight, etc., to achieve the effect of easy and fast assembly and safe lifting, light weight, and reduced welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

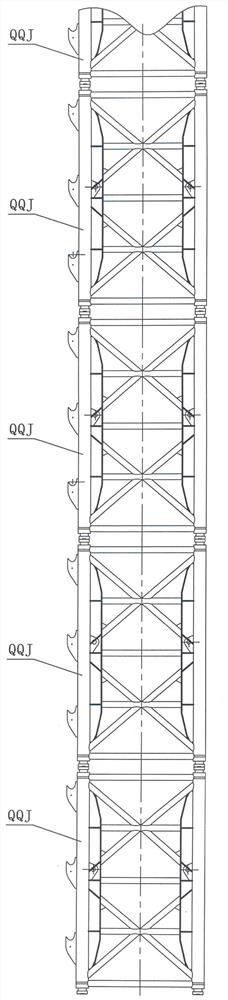

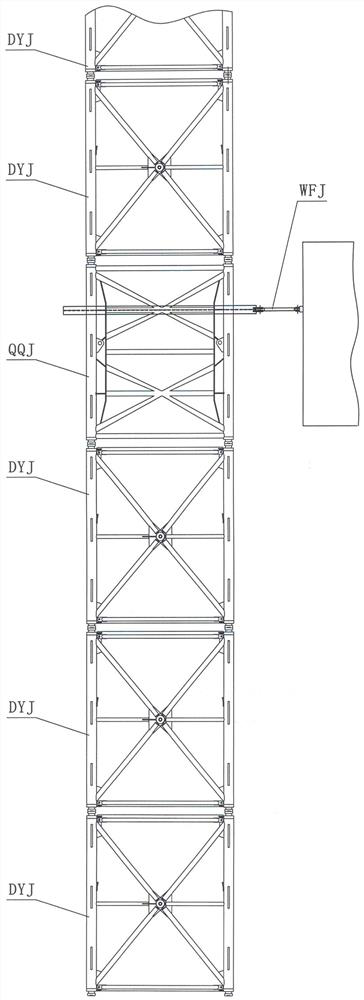

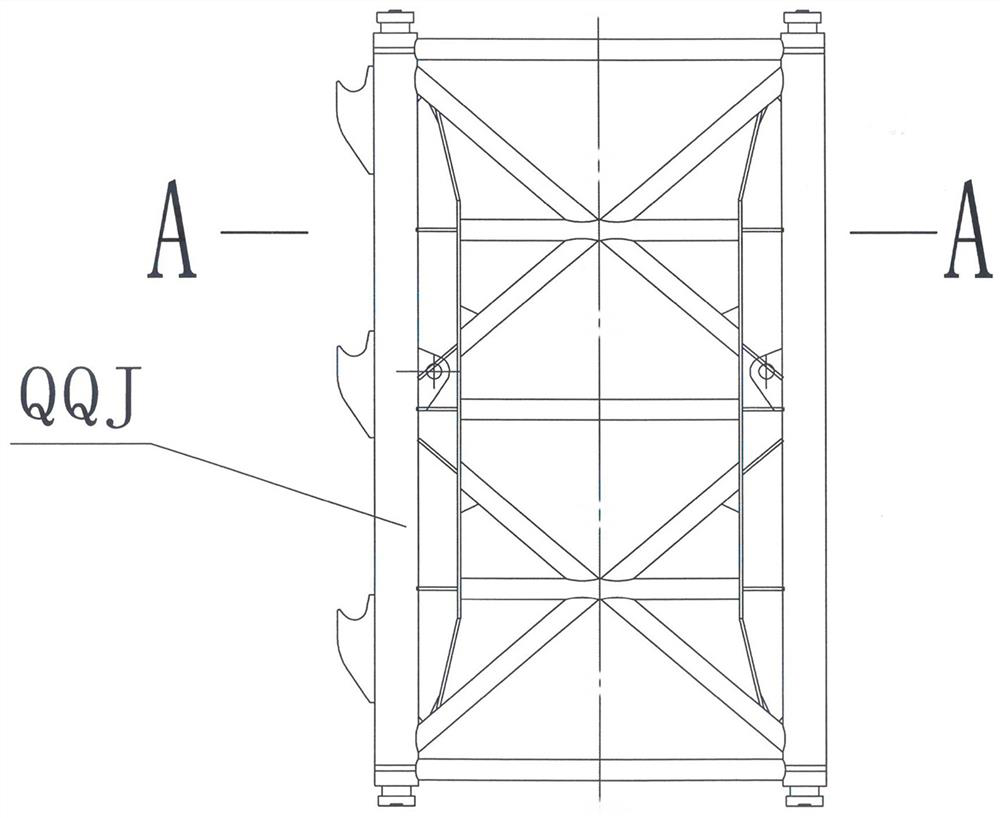

[0031] Such as Figure 6 ~ Figure 9 As shown, a light-weight attachment joint that is easy to assemble and lift in Embodiment 1 is composed of four identical vertical chords 1, an upper, middle and lower three-layer cross-web rod group 2 hingedly connected to the vertical chords, arranged on each The cuboid frame (as the stiffness skeleton of the attachment joint) composed of eight sets of façade web bar groups 3 between two adjacent vertical chords and each adjacent two-layer transverse web bar group, in the upper half of the cavity of the cuboid frame There are several layers of horizontally reinforced web members 4 in the way of hinged connection (this can improve the flexural modulus of the vertical chords and attachment joints, and meet the load requirements of the adhesion on the tower body structure), in the upper half of the four vertical chords The inner sides are all provided with vertical stiffeners 5 (this can increase the shear area of the vertical chords and at...

Embodiment 2

[0037] Such as Figure 10 , Figure 11 As shown, the difference between embodiment two and embodiment one is that in embodiment two, several layers of horizontal reinforcing web bar groups 4 are arranged in a hinged connection mode in the lower half of the cuboid frame (which can improve The flexural modulus of the vertical chords and attachment joints meets the load requirements of the adhesion on the tower body structure), and vertical stiffeners 5 are arranged on the inner sides of the lower half of the four vertical chords (this can improve the vertical chord The shear area of the rod and the attachment joint meets the load requirements of the adhesion on the tower body structure); the horizontal reinforced web rod group 4 is composed of four horizontal diagonal braces 4-1 through the proximal connecting plate 4-2 and hinged Bolt 6 connects each near-end hingedly together, through the far-end connecting plate 4-3 and hinged bolt 6, each far-end is respectively hingedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com