Surface aeration method and equipment based on silk thread shearing sewage

A technology of surface aeration and silk thread, which is applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., and can solve problems such as reduced efficiency, clogging of mesopore diffusers, heavy maintenance workload, etc. , to achieve the effect of simple equipment structure, improved power efficiency and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

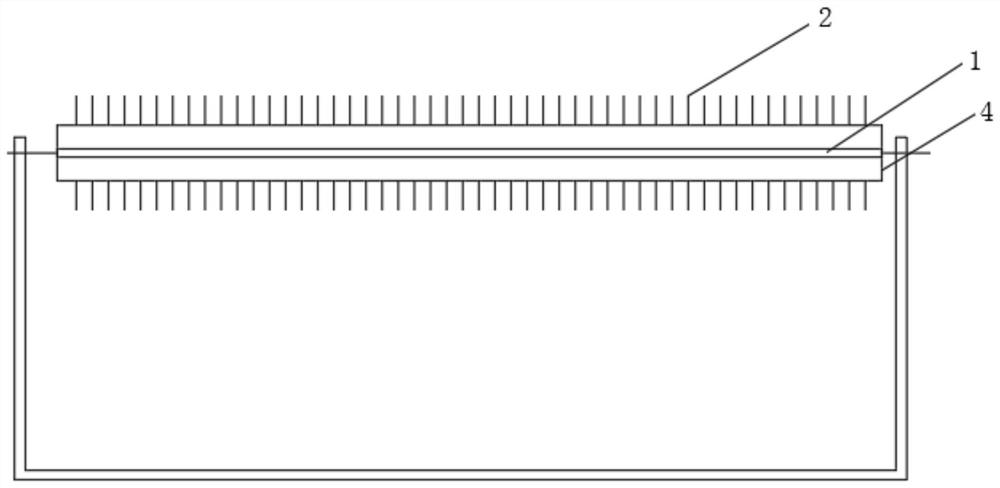

[0049] Implementation Mode 1: Horizontal Arrangement of Power Shaft - Shearing of Spring Steel Wire, see figure 1 .

[0050] The power shaft 1 placed horizontally is arranged about 0.2m above the water level of the aeration tank. The effective length of the power shaft 1 is equal to the width of the aeration tank. Several thin spring steel wires 2 are vertically welded on the power shaft 1 (or the spring steel wire 2 is welded on Connected to the cylinder 4 of the power shaft 1), the length of the spring steel wire 2 is 0.25-0.45m, and the submerged water depth is 0.05-0.25m deep (ignoring the diameter of the power shaft 1), and 6-10 rows of spring steel wire 2 can be welded on the power shaft 1 ( Take an even number), each row of spring steel wires 2 is staggered from the adjacent row of spring steel wires 2, that is, odd rows of spring steel wires 2 are aligned in the direction of rotation of the power shaft 1, and even rows are also aligned. But the spring steel wires 2 of...

Embodiment approach 2

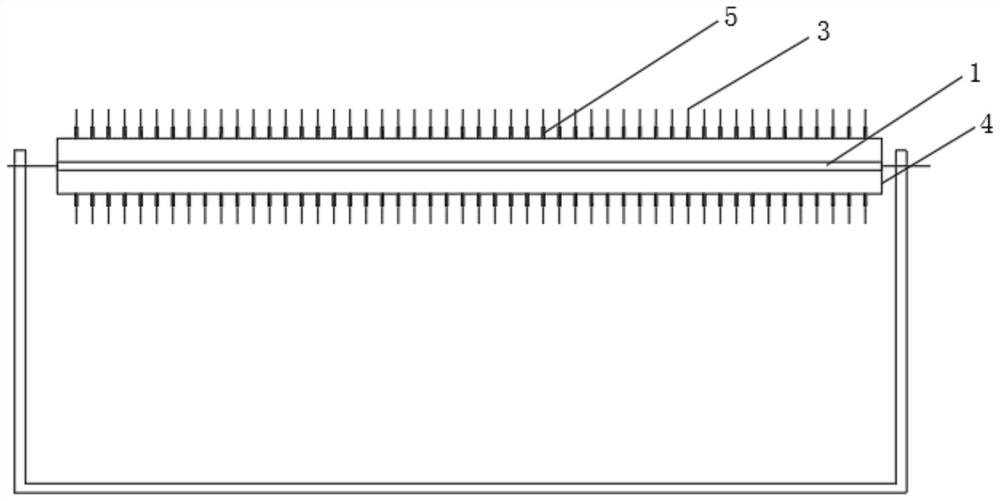

[0053] Embodiment 2: Horizontal arrangement of the power shaft 1 - shearing of the fiber thread 3, see figure 2 .

[0054] Others are the same as Embodiment 1, except that a steel bar 5 is provided at the end of the fiber thread 3 , and the end of the steel bar 5 is welded on the power shaft 1 to fix the fiber thread 3 on the steel bar 5 . The underwater part of the aeration equipment also has a steel bar 5 except the fiber thread 3 .

Embodiment approach 3

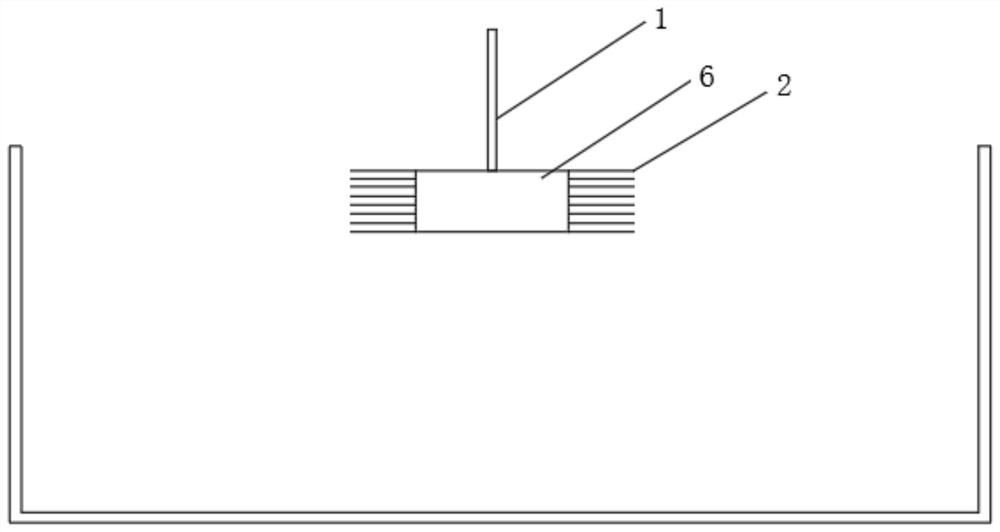

[0055] Implementation Mode Three: Vertical Arrangement Mode 1 of Power Shaft 1 - Shearing of Spring Steel Wire 2, see image 3 .

[0056] The motor is arranged at a certain position above the surface of the aeration tank, the power shaft 1 is perpendicular to the water surface, and a ring 6 is arranged at the end of the power shaft 1, and the center of the ring 6 is connected to the power shaft 1. When the power shaft 1 rotates, The circular ring 6 rotates, and the circular ring 6 is porous to ensure the lateral flow of water. The ring 6 is just submerged in water, and the height of the ring 6 is the depth of submersion. The diameter of the ring 6 is determined according to the shape of the aeration tank. Spring steel wires 2 are arranged outside the ring 6. The spring steel wires 2 are parallel to the water surface. The length of the spring steel wires 2 is 0.15-0.30m. When the motor is turned on, the rotation of the ring 6 drives the spring steel wires 2 to rotate and cut ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com