A device and method for solid-liquid separation combined with pressure swing adsorption for high-efficiency biogas production and purification

A solid-liquid separation and pressure swing adsorption technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of complex process structure, low separation efficiency, and bulky volume, and achieves optimized device structure, improved The efficiency of biogas production and the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

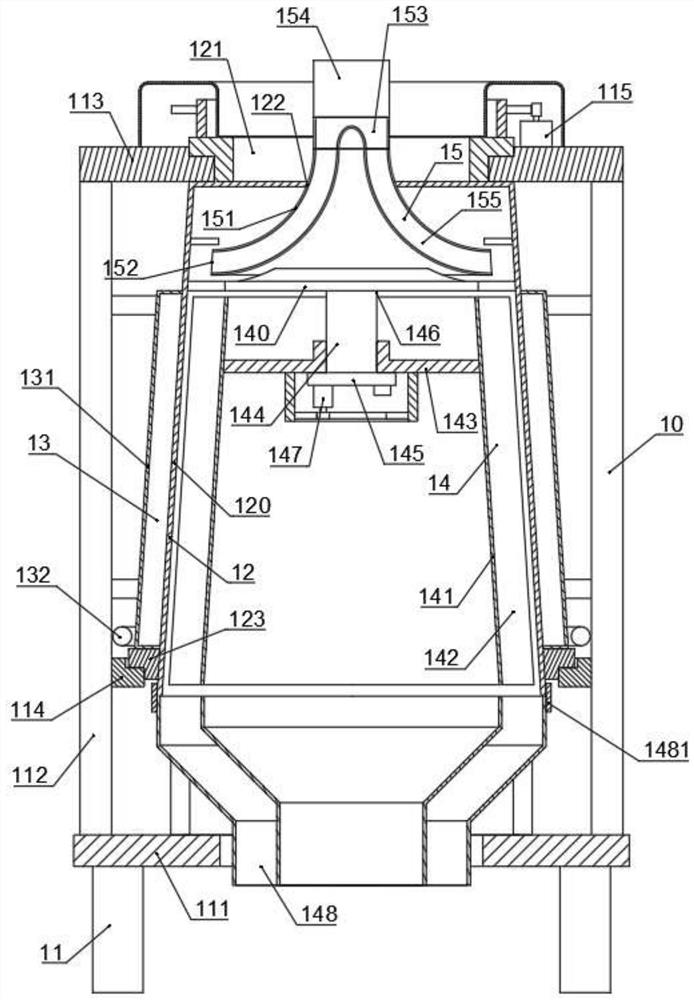

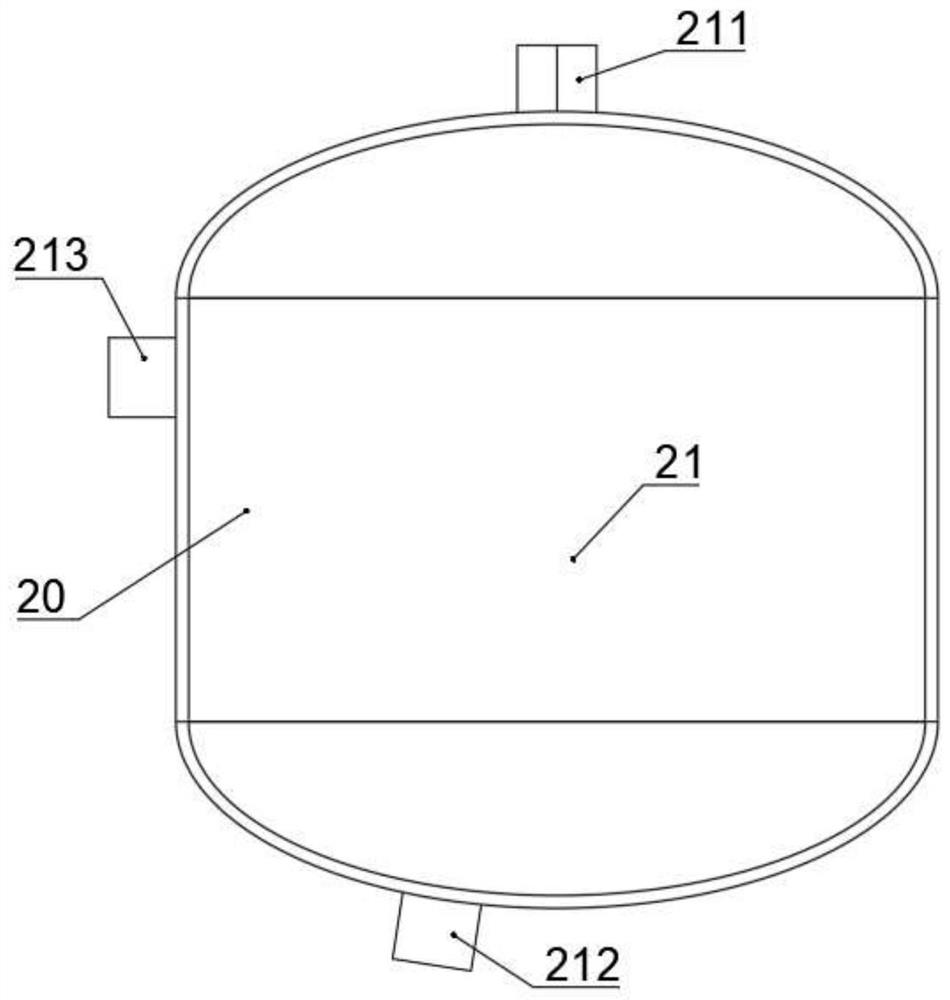

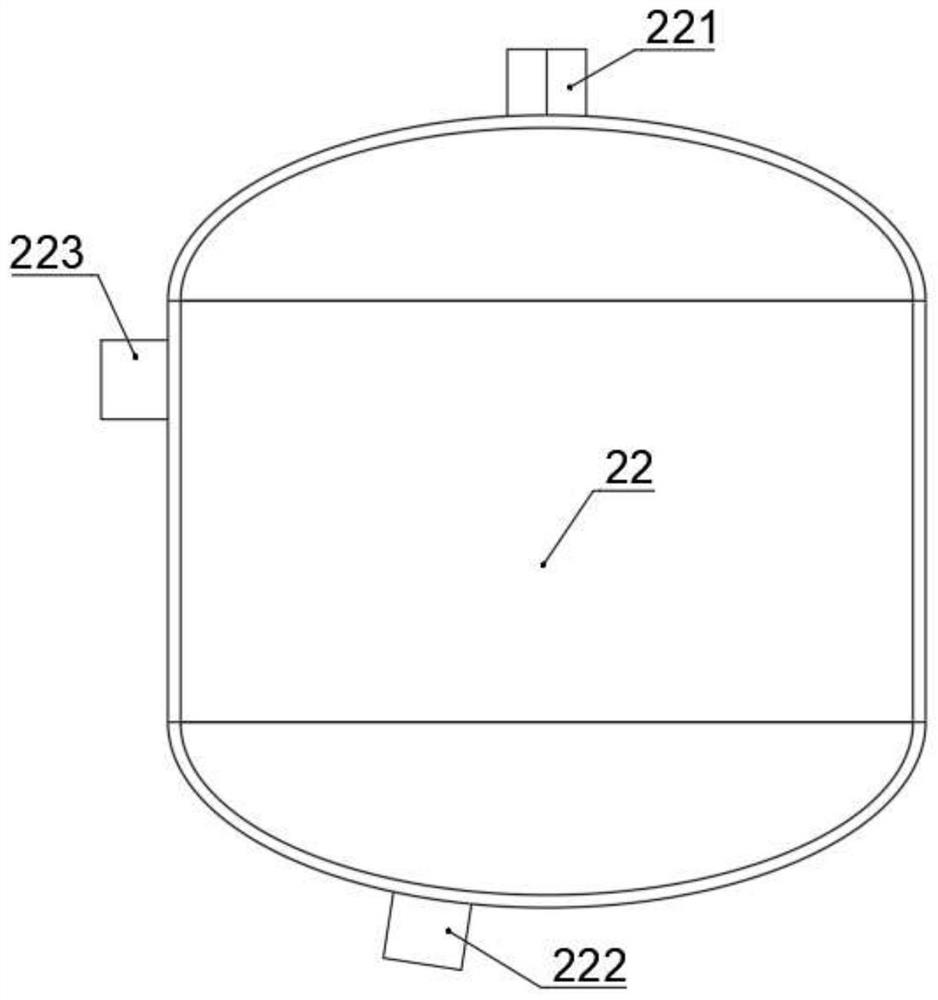

[0092] A device and method for solid-liquid separation combined with pressure swing adsorption for high-efficiency biogas production and purification, such as Figure 1-15 As shown, it includes a solid-liquid separation assembly 10, a gas production assembly 20 for fermenting the liquid components and solid components separated by the solid-liquid separation assembly 10 to produce biogas, and for producing the gas production assembly 20 The gas collection assembly 30 for centrally storing the biogas, the desulfurization drying tower 40 for desulfurization and drying of the biogas stored in the gas collection assembly 30, and the filtration treatment for the biogas treated by the desulfurization drying tower 40 The filter tower 50, the primary adsorption tank 60 and the secondary adsorption tank 70 used to absorb and purify the biogas, and the purified adsorbent used in the primary adsorption tank 60 and the secondary adsorption tank 70 Auxiliary vacuum tank 80 for regeneration...

Embodiment 2

[0121] The difference from Embodiment 1 is that the taper of the centrifuge tank 12 is 0.12, and the circumferential rotation angle of the feeding guide plate 155 extending from top to bottom is 130°.

Embodiment 3

[0123] The difference from Embodiment 1 is that the taper range of the centrifuge tank 12 is 0.16, and the circumferential rotation angle of the feeding guide plate 155 extending from top to bottom is 180°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com