Efficient welding bridge steel and manufacturing method thereof

A manufacturing method and bridge steel technology, applied in the field of iron and steel production, can solve problems such as weakening of welding and welding area strength, unqualified welding area flaw detection, and affecting mechanical properties of products, so as to avoid strength loss, eliminate adverse effects, and improve uniformity of structure sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

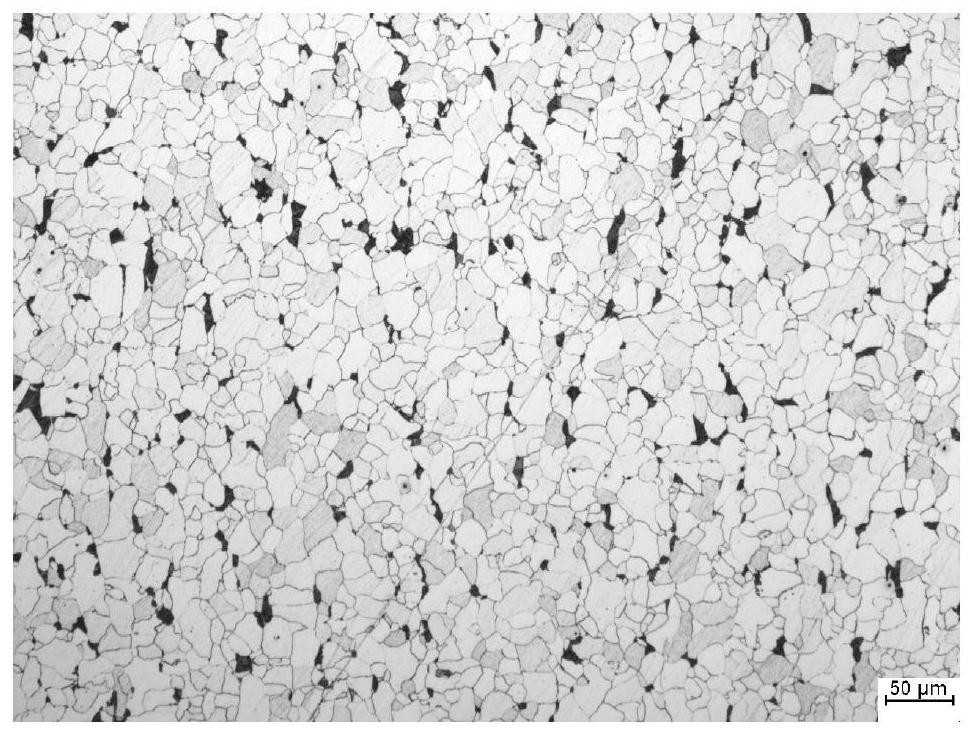

Image

Examples

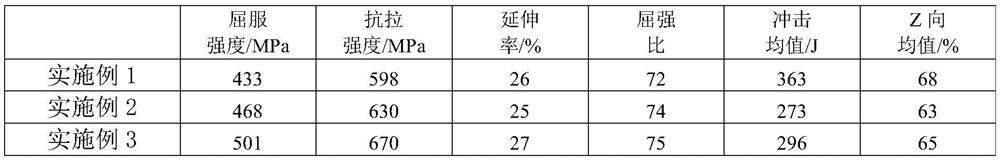

Embodiment 1

[0036] A high-efficiency welded bridge steel provided in this example has the following chemical composition and mass percentage: C: 0.06%, Si: 0.130%, Mn: 1.15%, P: 0.011%, S: 0.0020%, Nb: 0.026%, V: 0.016%, Ti: 0.017%, Cr: 0.02%, Ni: 0.19%, Mo: 0.01%, Cu: 0.03%, B: 0.0002%, Al: 0.029%, Mg: 0.0023%, N: 0.00350%, Ca is not added, and the balance is Fe and impurities.

[0037] Its manufacturing method comprises the following steps:

[0038] S1. Converter or electric furnace is used for molten steel smelting, the steel is fully deoxidized, and the aluminum content after the furnace is 0.041%;

[0039] S2. Using LF for desulfurization and slagging, alloying according to the composition design, without magnesium alloy treatment;

[0040] S3. Use RH or VD for vacuum treatment, feed magnesium aluminum wire after vacuum treatment, magnesium content is 0.0033%, and statically stir for 15 minutes after magnesium treatment;

[0041] S4. Continuous casting adopts ventilating nozzle to...

Embodiment 2

[0047] A high-efficiency welded bridge steel provided in this example differs from Example 1 in that its chemical composition and mass percentage are as follows: C: 0.068%, Si: 0.23%, Mn: 1.35%, P: 0.011%, S: 0.00150%, Nb: 0.033%, V: 0.026%, Ti: 0.016%, Cr: 0.02%, Ni: 0.22%, Mo: 0.03%, Cu: 0.02%, B: 0.0001%, Al: 0.041%, Mg: 0.0021%, N: 0.0043%, no Ca is added, the balance is Fe and impurities.

Embodiment 3

[0049] A high-efficiency welded bridge steel provided in this example differs from Example 1 in that its chemical composition and mass percentage are as follows: C: 0.073%, Si: 0.23%, Mn: 1.44%, P: 0.010%, S: 0.0010%, Nb: 0.036%, V: 0.033%, Ti: 0.016%, Cr: 0.02%, Ni: 0.27%, Mo: 0.02%, Cu: 0.02%, B: 0.0001%, Al: 0.039%, Mg: 0.0013%, N: 0.0029%, no Ca is added, the balance is Fe and impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com