Reinforced cement movable mobile house

A technology of reinforced concrete and movable houses, which is applied to residential buildings, building components, and fire prevention. It can solve the problems of poor overall solidity and durability, limited security and anti-theft performance, and large impact of external forces. performance, the effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

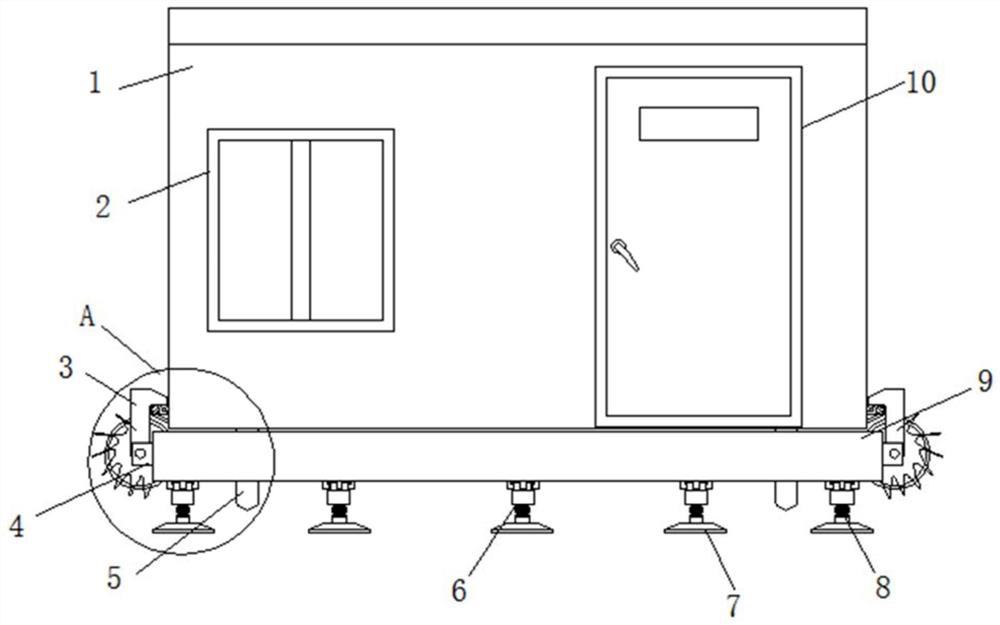

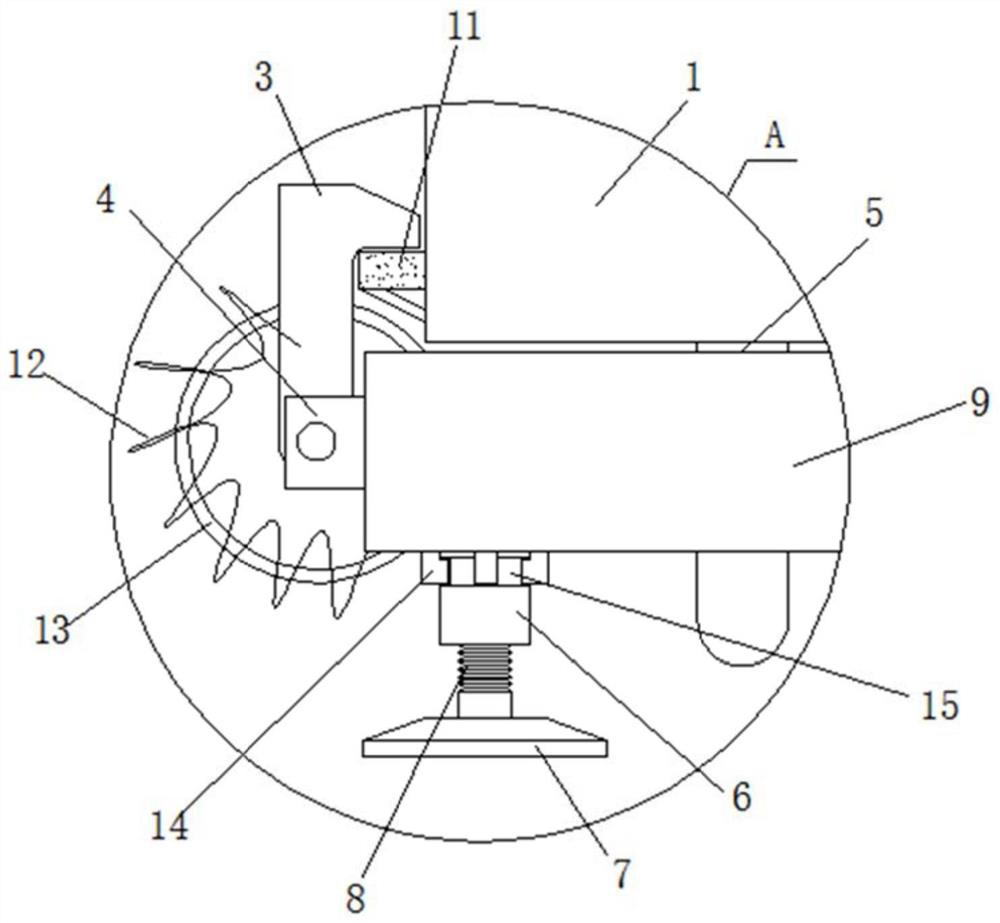

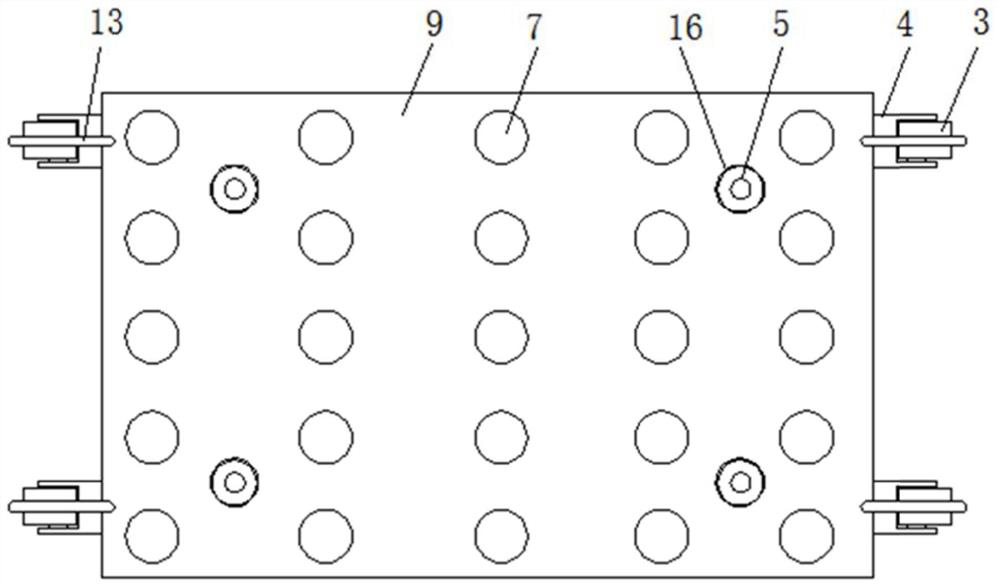

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution: a reinforced concrete movable house, including a house body 1, a bottom plate 9 is provided at the bottom of the house body 1, and mounting frames 4 are fixed at the four corners of the side walls of the bottom plate 9. Blocks 11 are fixed at the four corners of the side wall of the body 1, and the inside of the installation frame 4 is connected to the frame 3 through the rotation of the shaft column. Through the design of the frame 3 and the block 11, the frame 3 is stuck on the block by rotating one end 11 is clamped and connected, so as to realize fast assembly and fixation between the room body 1 and the bottom plate 9, which greatly reduces the difficulty of assembly. One end of the card frame 3 is placed on the top of the block 11, and the bottom end of the bottom plate 9 is provided with a rotary cylinder 6. Through The designed rotary drum 6 and screw rod 8, rotating the rotary drum...

Embodiment 2

[0027] see Figure 1 to Figure 4 , the present invention provides a technical solution: a reinforced concrete movable house, including a house body 1, a bottom plate 9 is provided at the bottom of the house body 1, and mounting frames 4 are fixed at the four corners of the side walls of the bottom plate 9. Blocks 11 are fixed at the four corners of the side wall of the body 1, and the inside of the installation frame 4 is connected to the frame 3 through the rotation of the shaft column. Through the design of the frame 3 and the block 11, the frame 3 is stuck on the block by rotating one end 11 is clamped and connected, so as to realize fast assembly and fixation between the room body 1 and the bottom plate 9, which greatly reduces the difficulty of assembly. One end of the card frame 3 is placed on the top of the block 11, and the bottom end of the bottom plate 9 is provided with a rotary cylinder 6. Through The designed rotary drum 6 and screw rod 8, rotating the rotary drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com