Gas recycling device of round tube high-temperature creep fatigue tester

A technology of high-temperature creep and gas circulation, which is applied in the direction of gas collection devices, gas storage and transportation devices, and measurement devices, can solve problems such as resource waste, undiscovered test gas collection and recovery, unfavorable test development, etc., to save time, The effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

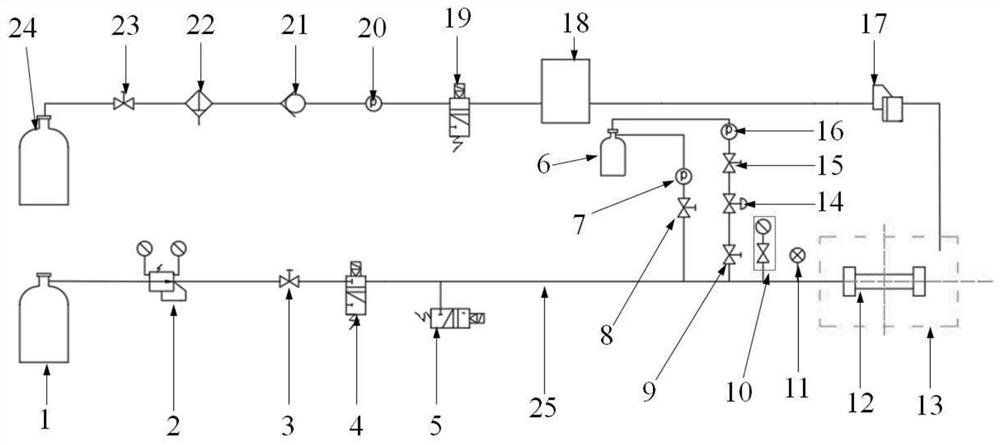

[0019] Example: such as figure 1 As shown, a gas circulation recovery device for a circular tube high-temperature creep fatigue tester is mainly composed of a high-pressure gas cylinder 1, a gas cylinder decompression valve 2, a first valve 3, a pressure solenoid valve 4, a load solenoid valve 5, a temporary Gas cylinder 6, first compressor 7, second valve 8, third valve 9, pressure gauge 10, pressure sensor 11, round tube sample 12, furnace body 13, air control needle valve 14, manual needle valve 15 , second compressor 16, safety valve 17, gas treatment pool 18, driving solenoid valve 19, third compressor 20, one-way valve 21, air filter 22, fourth valve 23, gas recovery bottle 24 and pipeline 25 A pipeline 25 is connected between the above-mentioned high-pressure gas cylinder 1 and the above-mentioned furnace body 13, between the above-mentioned furnace body 13 and the above-mentioned gas treatment pool 18, between the above-mentioned gas treatment pool 18 and the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com