Intelligent cooling control method for transformer

A cooling control and transformer technology, applied in the direction of transformer/inductor cooling, non-electric variable control, temperature control, etc. Service life and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

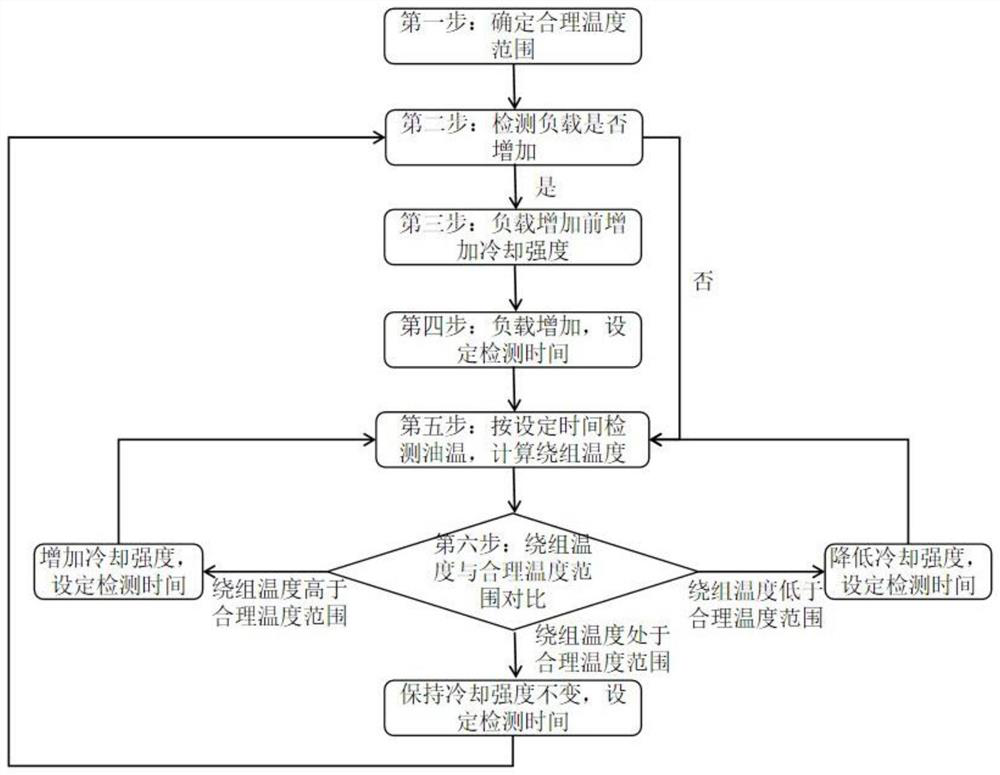

[0028] like figure 1 Shown is a step-by-step flow chart of a transformer intelligent cooling control method, and the method specifically includes the following steps:

[0029] The first step: According to the service life of the transformer, equipment parameters and physical and chemical indicators of the cooling fluid, determine the maximum temperature that the transformer winding can withstand when maintaining its normal life. Taking the maximum temperature as the upper limit, set a lower limit temperature, the maximum temperature and the lower limit temperature constitute a target operating temperature range for the transformer to realize the maximum utilization value, and execute the second step.

[0030] Step 2: Detect whether the operating load of the transformer increases, if not, skip to step 5, and if it increases, execute step 3.

[0031] Step 3: Increase the cooling intensity of the cooling system before the transformer operating load increases, so as to prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com